Adjacent-chamber object conveying mechanism for medical instrument production

A technology of medical equipment and room transmission, which is applied in the direction of transportation and packaging, slideways, etc., can solve the problems of laborious noise, pollution, etc., and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

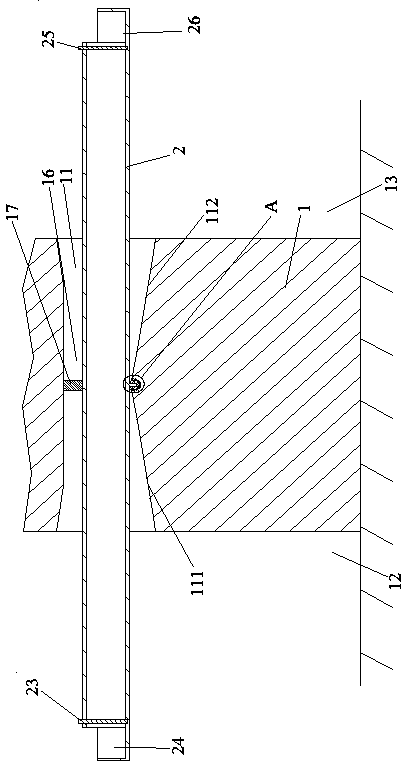

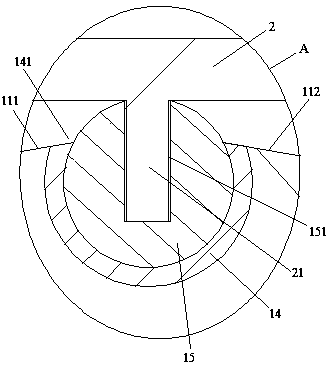

[0018] Embodiment one, see figure 1 with figure 2 , an adjacent chamber transfer mechanism for medical device production, comprising a left chamber 12 and a right chamber 13 separated by a wall 1 . The wall 1 is provided with a communicating hole 11 communicating the left ventricle and the right ventricle. A left inclined section 111 is provided at the left end of the bottom wall of the communication hole, and a right inclined section 112 is provided at the right end. A round steel pipe 14 is poured at the junction of the left inclined section and the right inclined section. The round steel pipe extends horizontally and is perpendicular to the center line of the communication hole. An opening 141 is provided on the upper portion of the peripheral surface of the round steel pipe. The opening extends along the axial direction of the round steel pipe. The round steel pipe is worn on the rotating shaft 15. The upper side of the rotating shaft is exposed in the communication...

Embodiment 2

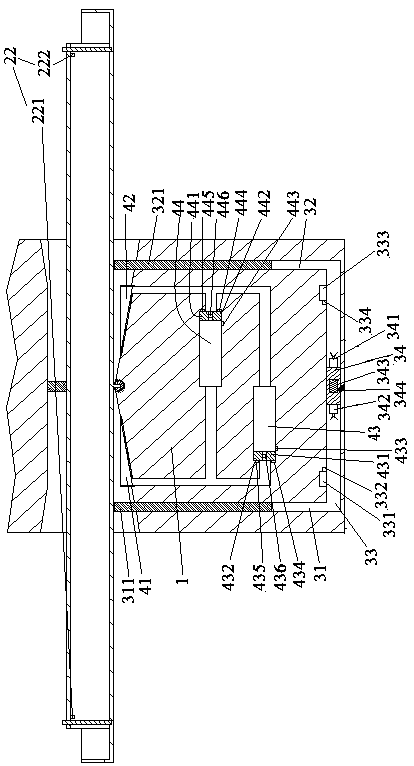

[0021] Embodiment two, the difference with embodiment one is:

[0022] see image 3, the wall 1 is provided with a left vertical hole 31, a right vertical hole 32 and a sliding hole 33 communicating with the left vertical hole and the right vertical hole. The upper end of the left vertical hole is sealed and slidably pierced with a left push rod 311 supported on the left end of the feeding pipe. The upper end of the right vertical hole is sealed and slidably pierced with a right push rod 321 supported on the right end of the feed pipe. The sliding hole, the left vertical hole and the right vertical rod are filled with hydraulic oil. A piston 34 is sealed and slidably connected in the sliding hole. One end of the piston is connected with a left push propeller 341 which drives the piston to move towards the left vertical hole, and the other end is connected with a right push propeller 342 which drives the piston to move towards the right vertical hole. The piston is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com