Cord fabric separating and rolling device for elevation stand cutting machine

A technology of coiling device and cutting machine, which is applied in the field of machinery, can solve the problem of easy dust accumulation of the cord, achieve the effect of removing static electricity, strengthening the effect of dust removal, and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

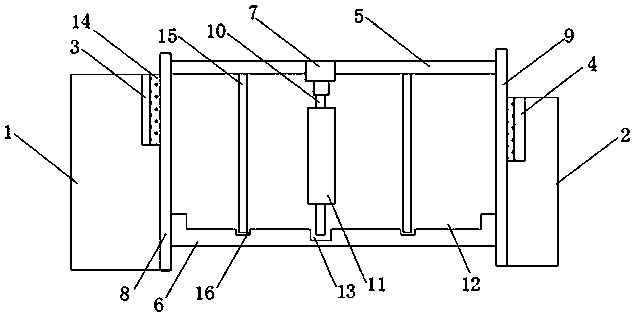

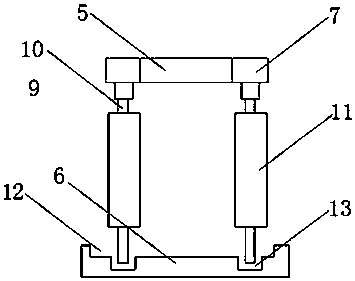

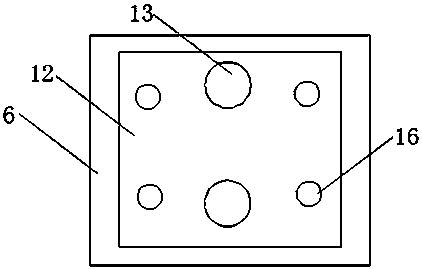

[0030] see Figure 1-4 , the high platform cutting machine cord separation and coiling device, including the coiler body 2 located on the right side of the cutting machine body 1, the right side of the cutting machine body 1 is provided with a side cloth outlet 3, and the left side of the coiler body 2 is provided with a Side roll cloth opening 4, a cleaning device is arranged between the cutting machine body 1 and the coiler body 2, the cleaning device includes a fixed frame, an upper support plate 5, a lower support plate 6 and a motor 7, and the fixed frame includes a first fixed rod 8 and the second fixed rod 9, the first fixed rod 8 is fixedly connected to the front and rear ends of the cutting machine body 1, the second fixed rod 9 is fixedly connected to the front and rear ends of the coiler body 2, and the upper support plate 5 The left and right ends are respectively fixedly connected to the upper end of the first fixed rod 8 and the upper end of the second fixed rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com