An Adaptive Damping Shock Absorber Cable Joint

A shock absorber and self-adaptive technology, applied in the direction of the linear motion axis, etc., can solve the problems of stiff gear shifting and shifting handle vibration, etc., and achieve the effects of weakening vibration energy, improving smoothness and softness, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

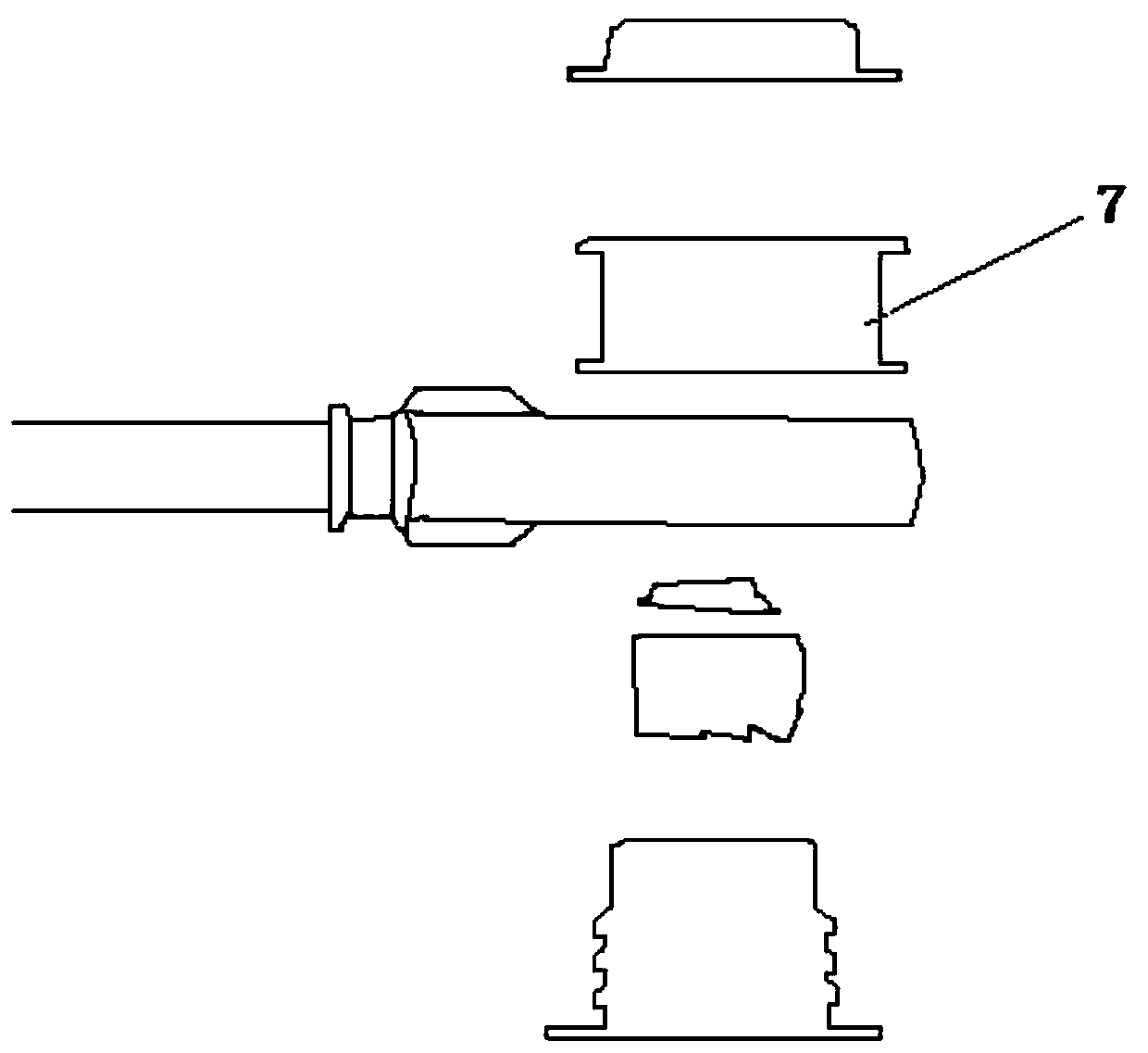

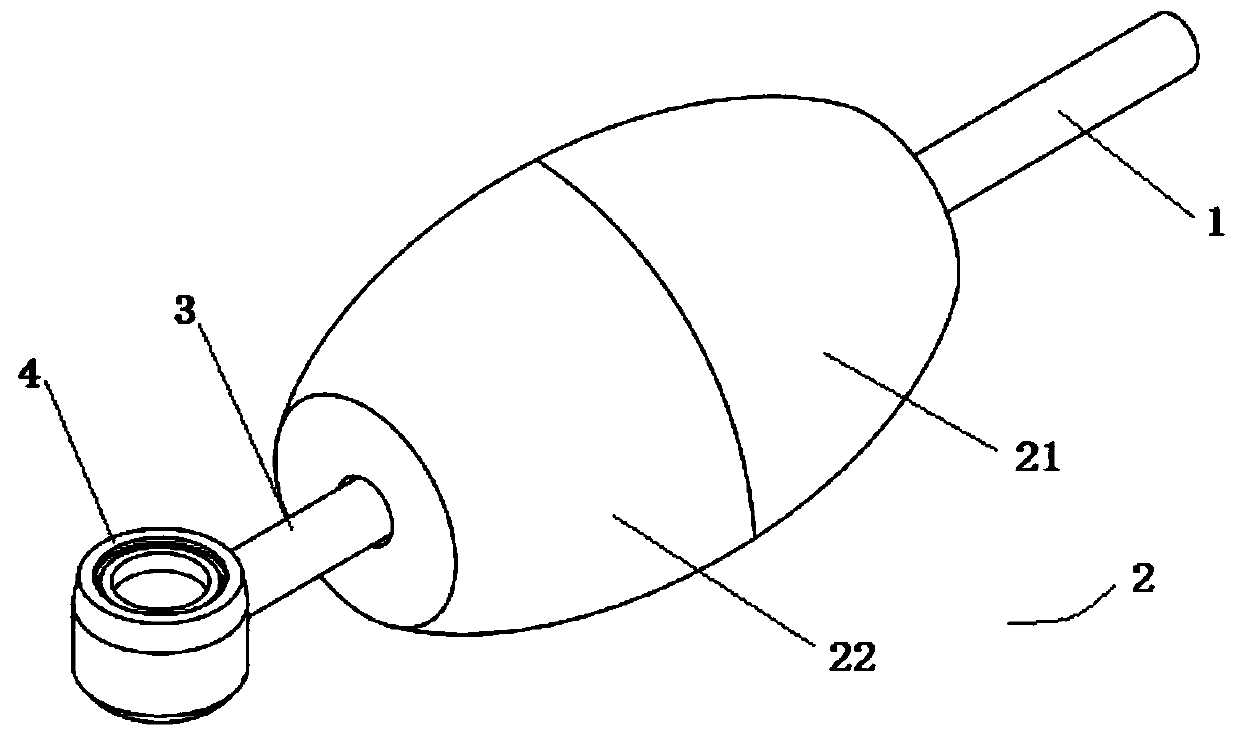

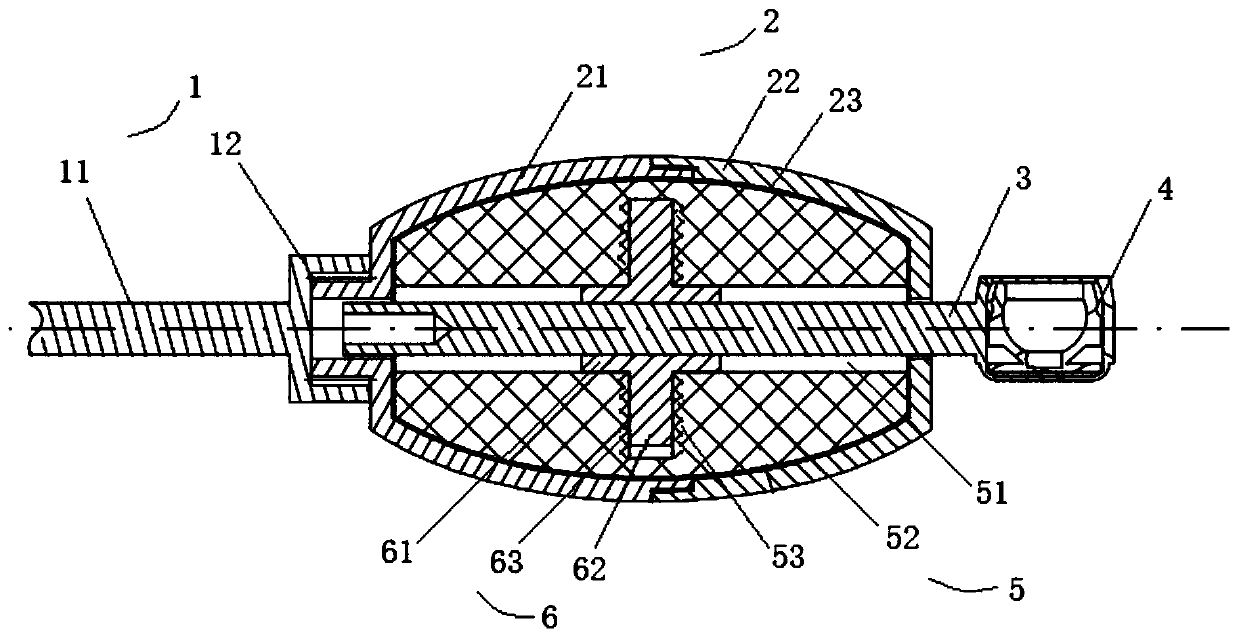

[0031] In order to solve the problems in the prior art, the present invention provides an adaptive damping shock absorber cable joint, see figure 2 , image 3 with Figure 4 , the cable joint includes a metal rod 1 at the active end of the cable and a metal rod 3 at the cable joint end, a flange 6, a vibration-damping rubber spring 5 and a vibration-damping housing 2 that are sequentially sleeved from the inside to the outside. Specifically, The metal rod 1 at the driving end of the cable is connected to the shifter assembly through the shift cable sheath, and the driver operates the shift handle on the shifter assembly to switch gears of the transmission.

[0032]Further, the vibration-damping housing 2 is sleeved on the outside of the vibration-damping rubber spring 5 , and the flange 6 and the vibration-damping rubber spring 5 are both arranged in the inner cavity of the vibration-damping housing 2 middle. As preferably, the structure of the damping housing 2 is ellipso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com