Device and method for testing anti-scouring capability of soil body

A kind of ability and soil technology, which is applied in the field of devices for testing soil erosion resistance, can solve the problem of no experimental device for testing soil erosion resistance, and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

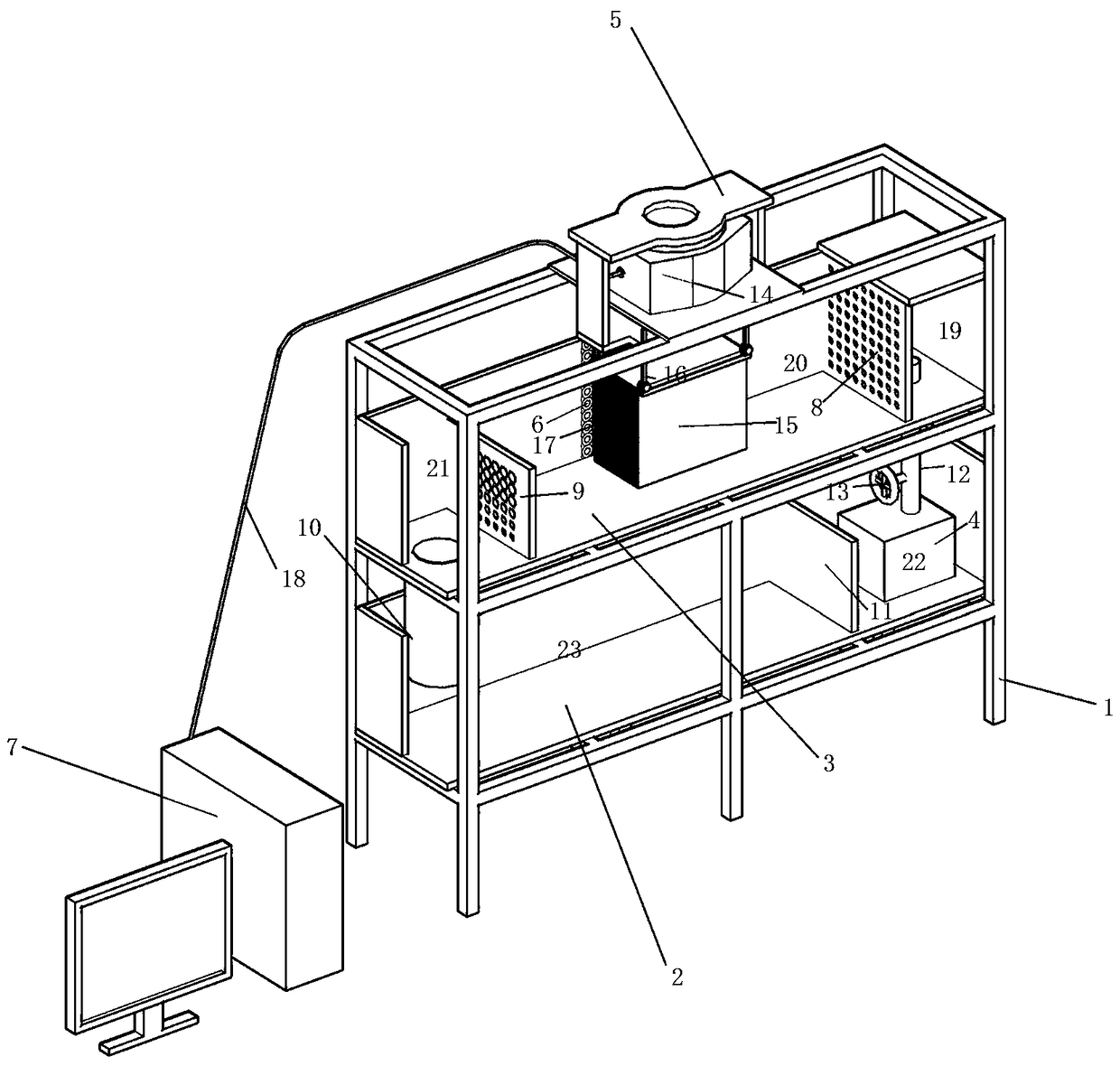

[0033] Such as figure 1 As shown, a device for testing the erosion resistance of the soil, including a load-bearing frame 1,

[0034] The load-bearing frame 1 is provided with an upper water tank 3 and a lower water tank 2, and the inner space of the upper water tank 3 is divided into a water flow entry section 19, a water flow stabilization section 20 and a water flow discharge section by a vertical water inlet mesh plate 8 and a drainage mesh plate 9 21 three parts, the hole diameter on the water inlet sieve plate 8 gradually decreases from top to bottom, so that the water flow for controlling the washing of the sample is stable; the hole diameter on the drainage sieve plate 9 gradually decreases from top to bottom, so that Control the steady flow of water between the two sieve plates.

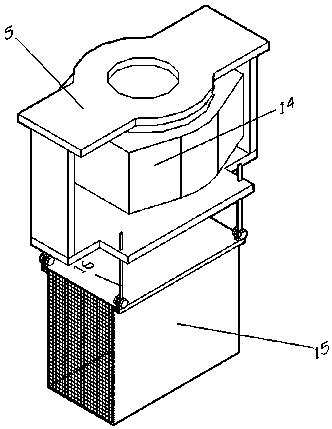

[0035] An electronic balance 14 is installed above the load-bearing frame 1, and the sample frame 5 is composed of a force transmission platform, a dowel bar 16 and a sample box 15. The sam...

Embodiment 2

[0043] A method for testing soil erosion resistance by using the above-mentioned device, the method includes the following steps:

[0044] Step 1: close the valve 13;

[0045] Step 2: Add water of 3 / 4 of the volume of the lower tank into the lower tank 2;

[0046] Step 3: Open the valve 13 and start the variable frequency water pump 4 at the same time;

[0047] Step 4: Continue to add water to the sink 2;

[0048] Step 5: The frequency conversion water pump 4 sends the water in the lower water tank 2 to the upper water tank 3 through the upper water pipe 12, until the upper water tank 3 and the lower water tank 2 form a circulation system through the frequency conversion water pump 4 and the connecting water channels at both ends, and then stop adding water;

[0049] Step 6: Put the prepared soil sample into the sample box 15, and then cover with a detachable plexiglass cover;

[0050] Step 7: Turn on the electronic balance 14, and reset the reading of the electronic balanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com