Solid herbicide composition containing fluorine to chlorine ratio

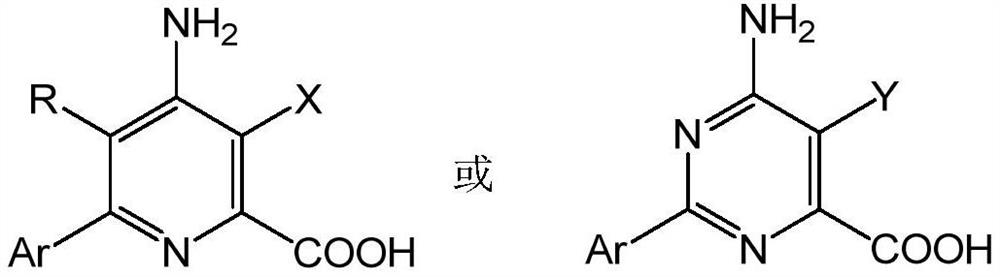

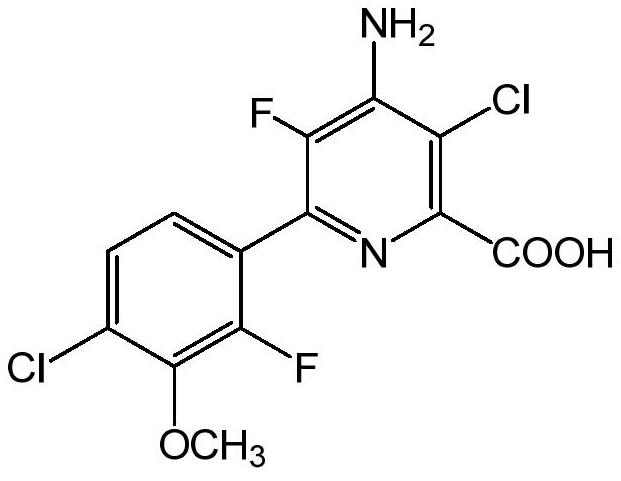

A fluorine-to-chlorine ratio, herbicide technology, applied in biocides, animal repellents, plant growth regulators, etc., can solve the problems of incompetent biological efficacy, inability to fully disperse solid preparations, and physical instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

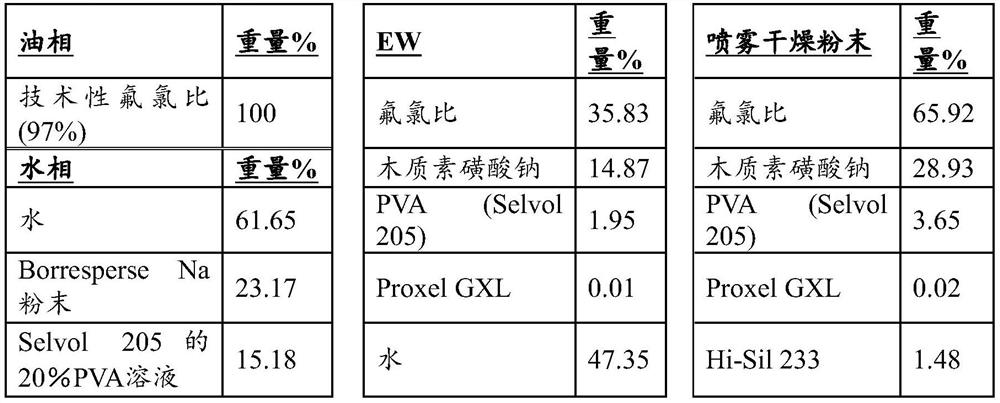

[0116] Example 1 . Preparation of said composition

[0117] sample 1 .Preparation of highly loaded herbicide granule compositions from spray-dried powders

[0118] The oil phase composition of the molten technical fluorine-to-chlorine ratio is heated between 70°C-80°C and a three-stage (coarse, medium and fine) type rotor-stator on-line homogenizer (IKA Magic LAB), with 1.79 water phase / oil phase flow ratio and the water phase (Table 1) also maintained between 70°C-80°C for on-line (in-line ) to form an oil-in-water emulsion having the following particle size distribution: d50 of about 3 micrometers (μm) and d90 of about 7 μm. A particle size distribution with a d50 of less than 2 μm is obtained when the tip speed is increased to about 25 m / s. Alternatively, an oil-in-water emulsion is prepared in batch mode by adding the heated oil phase to the heated water phase in a vessel with agitation and then recirculating it by passing it discretely through an in-line homogenizer ...

Embodiment 2

[0129] Example 2 .Storage Stability of Highly Loaded Herbicide Granular Compositions

[0130] Particle Size, Wet Sieving and Dispersion Time Test Methods

[0131] Particle size analysis : After dispersing a small sample of the extruded particles in 342 ppm hard water at room temperature, the particle size distribution of the resulting particle dispersion was determined using a Mastersizer 2000 laser diffraction particle size analyzer and reported as d in microns (μm) 50 / d 90 value.

[0132] wet sieve test : After dispersing a weighed sample of extruded particles in 342 ppm hard water at room temperature, the resulting particle dispersion and several water rinses were passed through a 200 mesh screen. The material remaining on the screen was dried, weighed and reported as weight % of the original test sample of extruded granules.

[0133] Dispersion time measurement

[0134] a) Weigh 0.1g of the particle sample into a 25mL beaker;

[0135] b) Add 100 mL of 342 ppm...

Embodiment 3

[0144] Example 3 . Differential Scanning Calorimetry Analysis of Spray Dried Powder (Sample 1)

[0145] Differential scanning calorimetry (DSC) indicated that the fluorine to chlorine ratio contained in the spray-dried powder (Table 3) reached almost complete crystallinity within about 48 hours after spray-drying.

[0146] DSC thermal data heat flow (absorption)

[0147] 100% crystalline fluorine to chlorine ratio sample 70.01J / g

[0148] Spray-dried powder (65.92% fluorine to chlorine ratio) 43.28J / g

[0149] (Fluorine to Chlorine Ratio in Spray Dried Powder) Calculation of crystallinity

[0150] Heat flow into spray dried powder (if 100% crystallized) = (70.01J / g) x 65.92% = 46.15J / g

[0151] Crystallinity of spray-dried powder = [(43.28J / g) / (46.15J / g)] x 100 = 93.8%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com