High frequency ultrasound transducer and method for manufacture

A transducer, ultrasonic technology, applied in the direction of fluid using vibration, ultrasonic/sonic/infrasonic diagnosis, application, etc., can solve problems such as error-prone, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

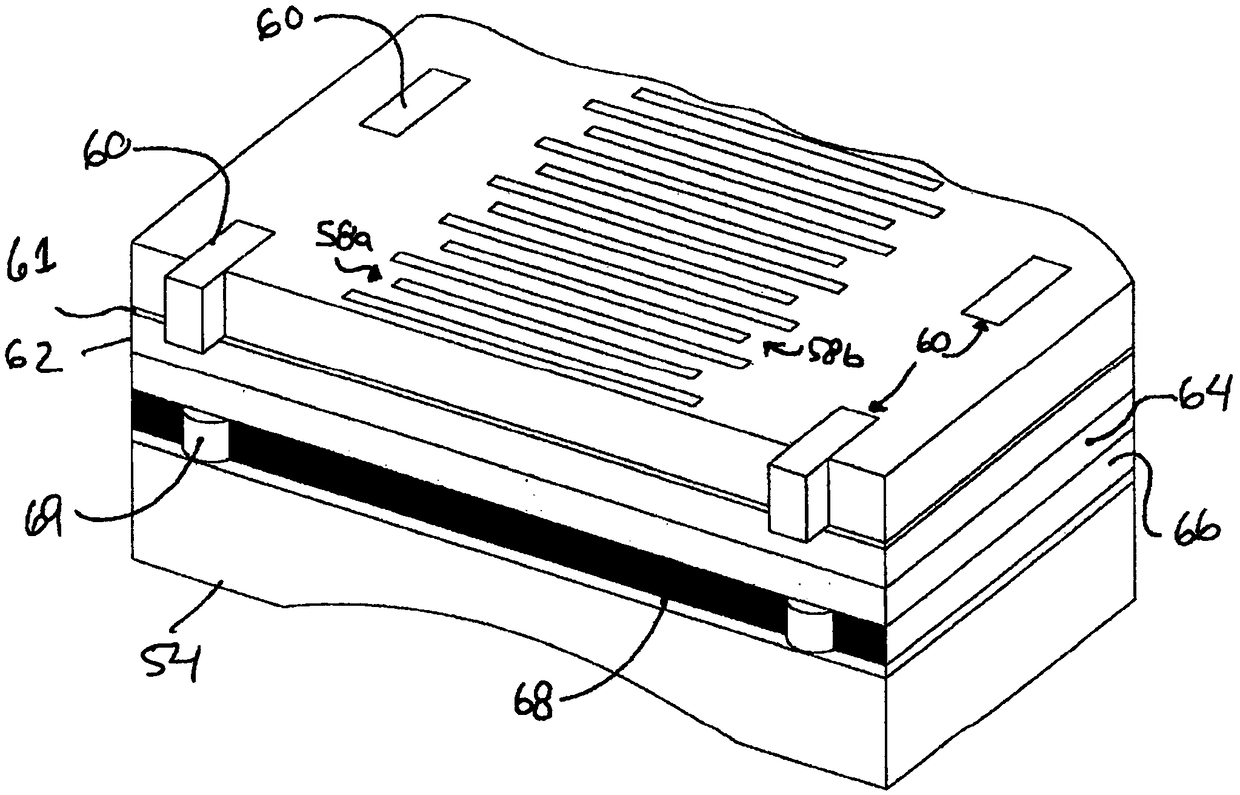

[0023] As mentioned above, one of the challenges associated with manufacturing high frequency ultrasound transducers is performing the step of electrically connecting multiple conductive leads or traces to the individual transducer elements of the transducer array without interrupting the array transduction. performance of device components. Previously the conductive traces had to be manually aligned to the transducer elements, after which they were handled with care until the manufacturing process was complete. Accidental bumping of the transducer assembly or improper alignment of the traces can result in part rejection. This problem becomes more acute as the operating frequency of ultrasonic transducers increases and the transducer elements are miniaturized. The techniques described herein simplify the manufacturing process steps of aligning and connecting the conductive traces to the individual transducer elements of a transducer array.

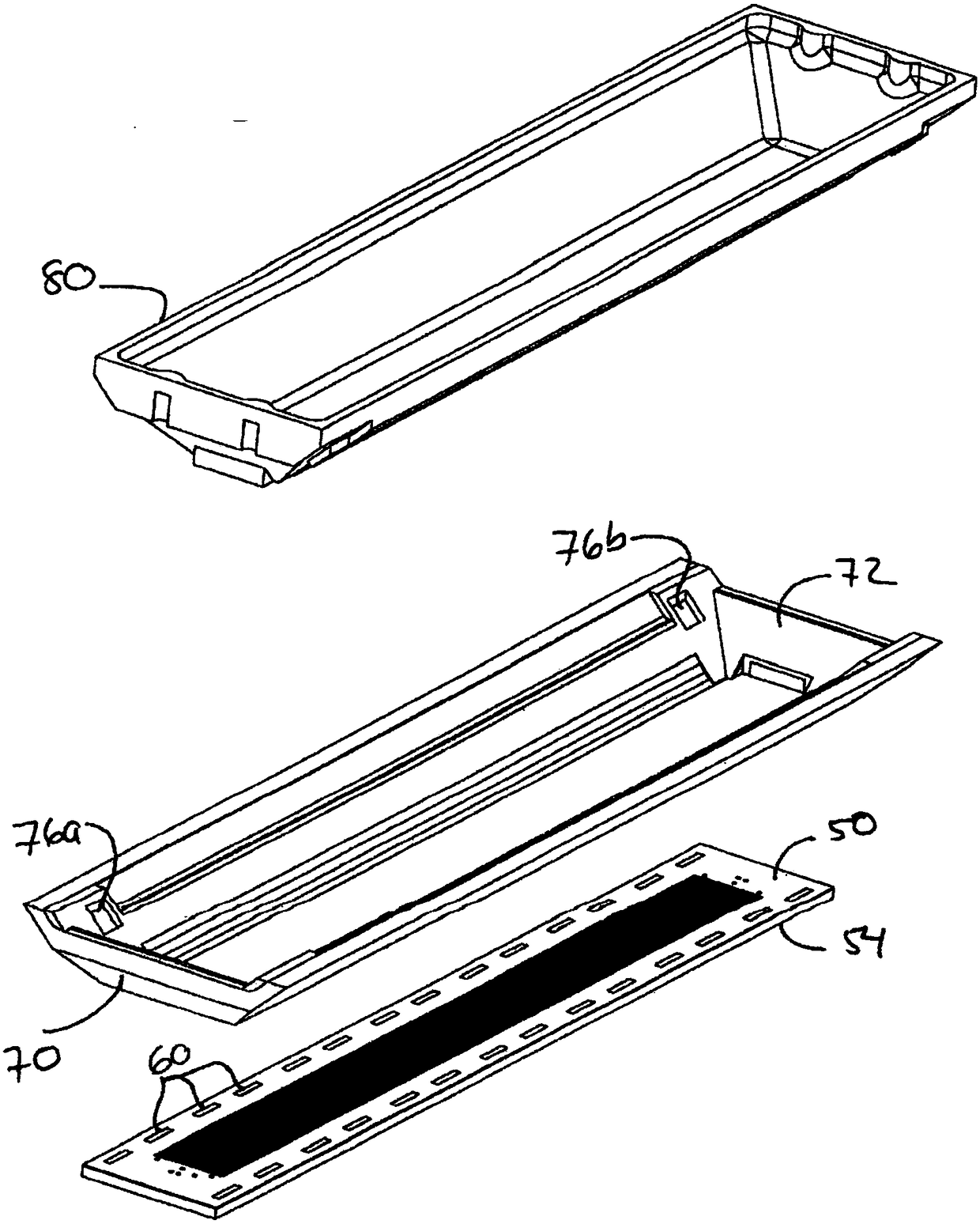

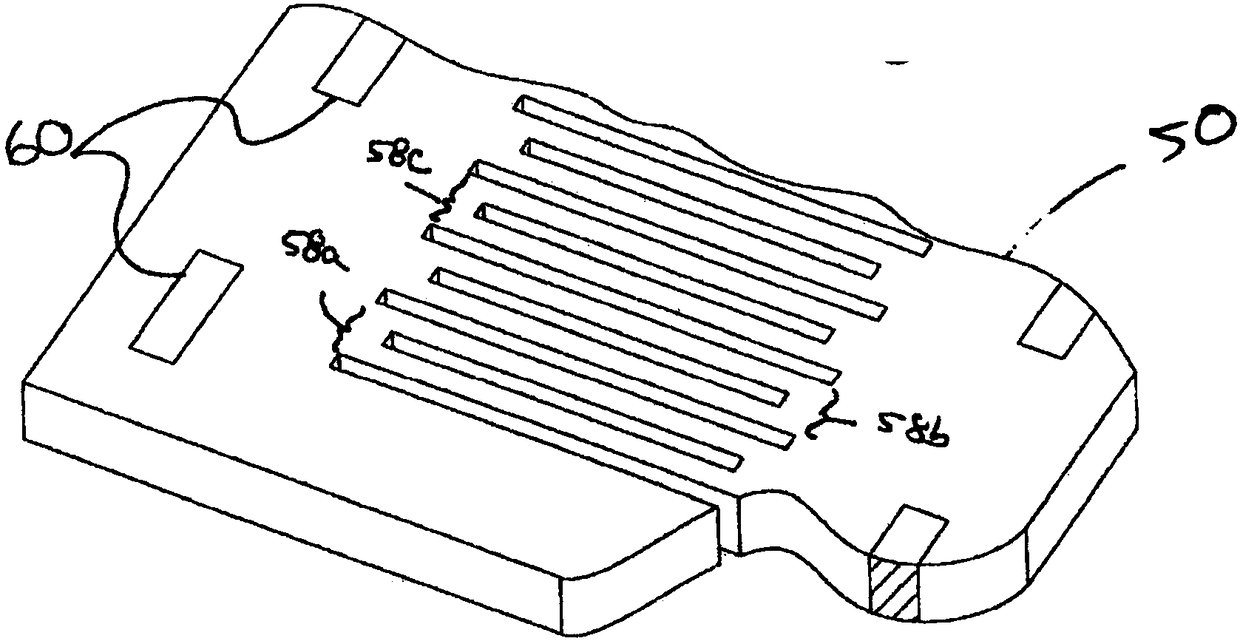

[0024] Figures 1A-1D and the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com