MOF complex and synthesizing method thereof and application of MOF complex for absorbing organic dye in waste water

A technology of complexes and dyes, applied in the direction of adsorption of water/sewage treatment, water pollutants, and other chemical processes, to achieve superior adsorption capacity, reduce pollution, and reduce treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The synthesis of the MOF complex of the present invention and the fluorescence recognition of Fe are as follows through specific examples 3+ method is further explained.

[0030] 1. Synthesis of MOF complexes

[0031] Ligand H 2 L (0.0226g, 0.1mmol) was dissolved in 6 mL of acetonitrile / water (1:1 v / v), then added to a 10mL reactor, and then 0.25 mL of Zn(NO 3 ) 2 ·6H 2 Aqueous solution of O (0.4 mol∙L -1 ), stirred to form a suspension. Then the suspension was placed in a 25 mL polytetrafluoroethylene autoclave and reacted at 140 °C for 4 days. When the temperature dropped to room temperature, a colorless flaky crystal was obtained, which was washed with distilled water and dried naturally to obtain the MOF complex. Yield 36.0%.

[0032] Infrared data (KBr, cm -1): 3500(m), 3105(m), 3023(w), 2922(m), 2856(w), 1574(s), 1376(m), 1288(w), 1142(w), 987(w ), 892(w), 756(w), 675(w).

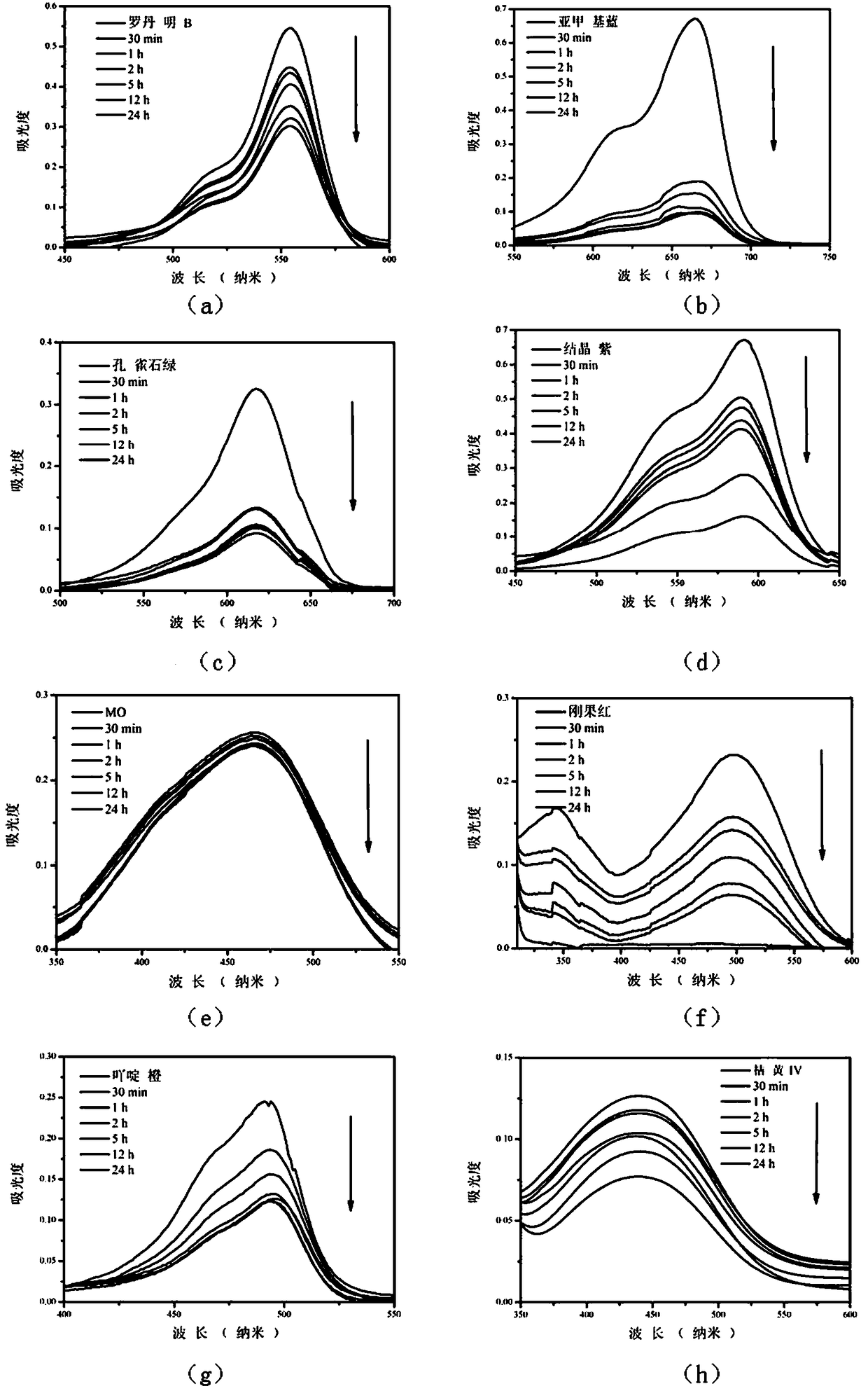

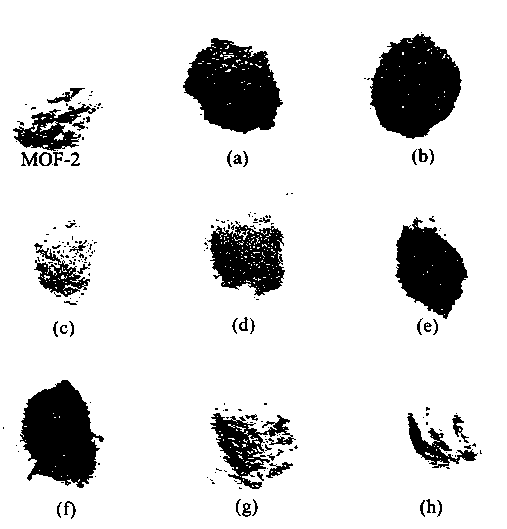

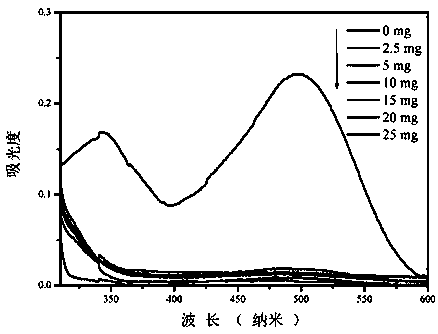

[0033] 2. Application of MOF complexes in the treatment of dye wastewater

[00...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap