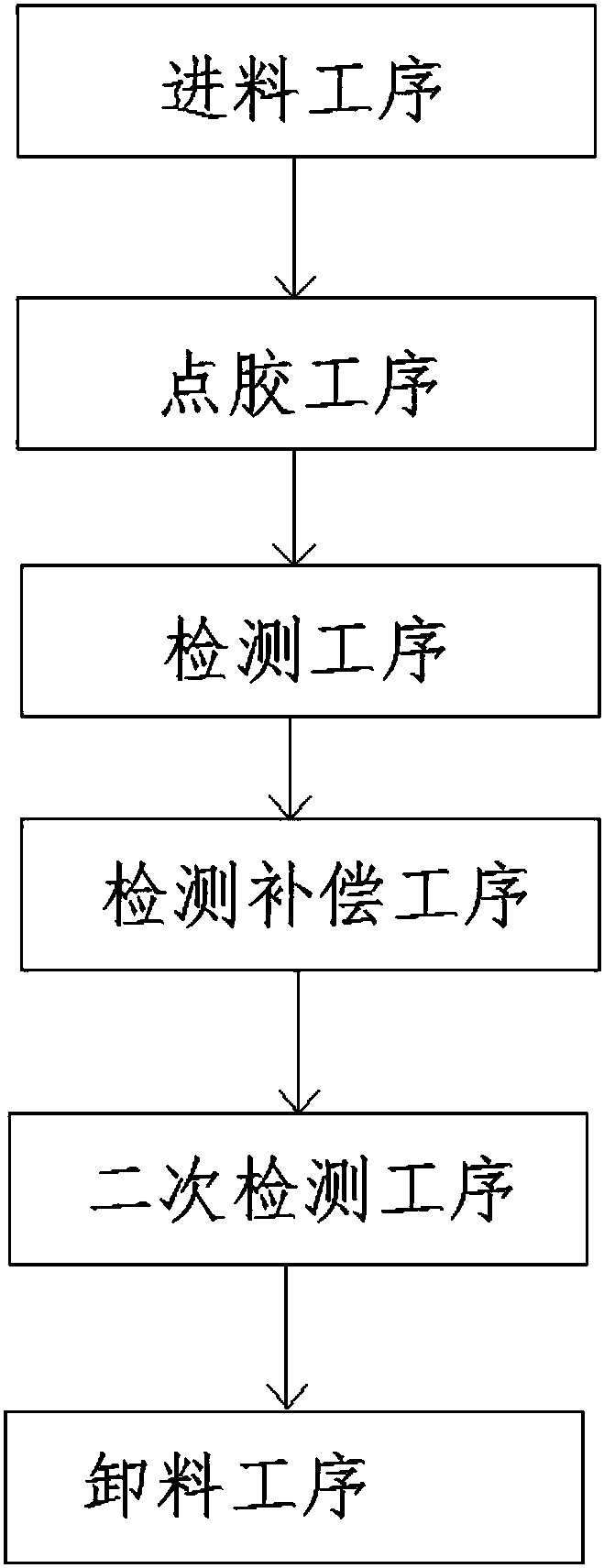

Online type automatic adhesive dispensing machine and adhesive dispensing process

A glue dispensing process and automatic dispensing technology, which is applied in coatings and devices for coating liquid on the surface, etc., can solve the problems of reducing brand competitiveness, complex disassembly engineering, and low volume cost, so as to prevent unqualified products from entering the market , Guarantee dispensing operation and high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

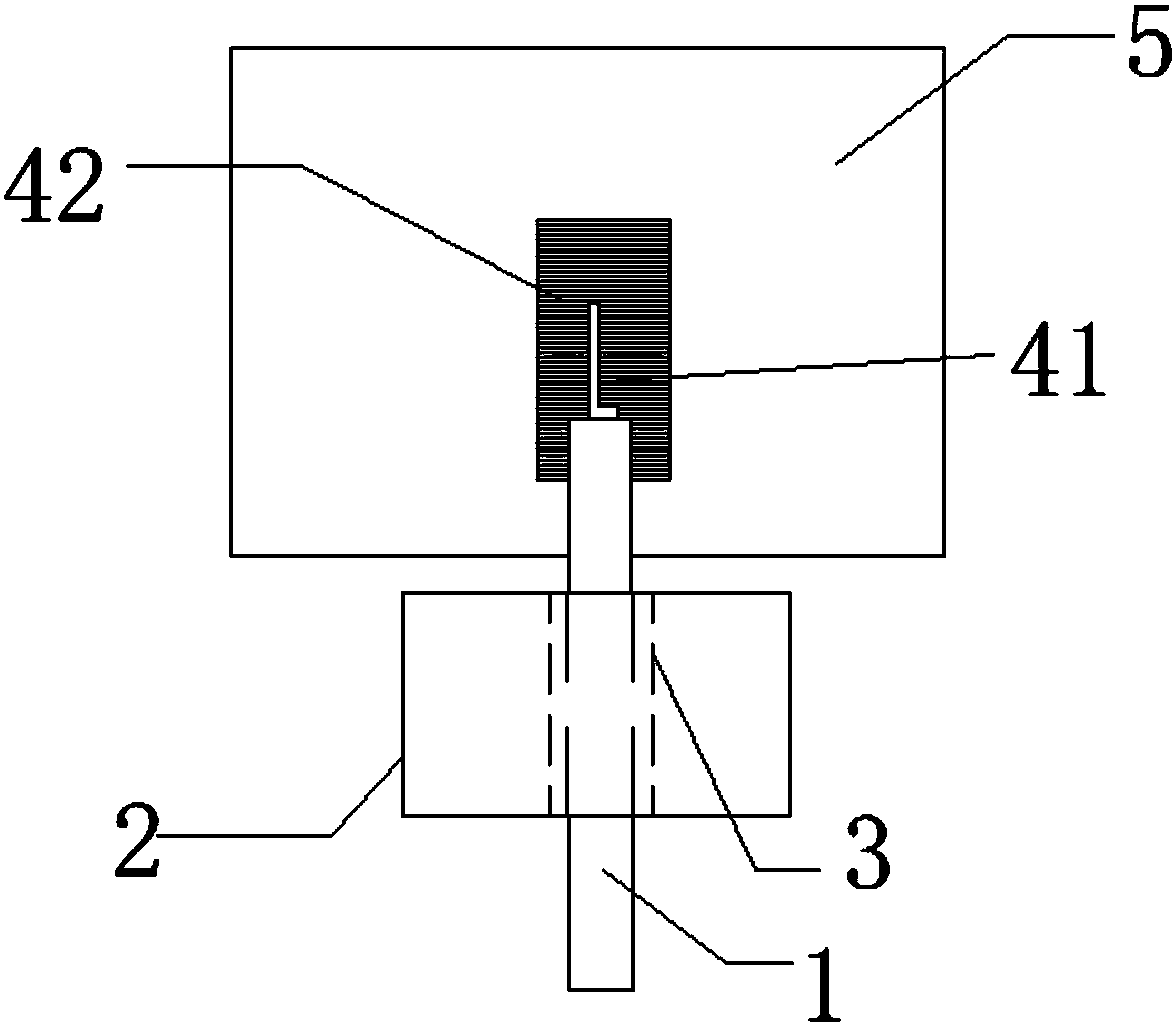

specific Embodiment example 1

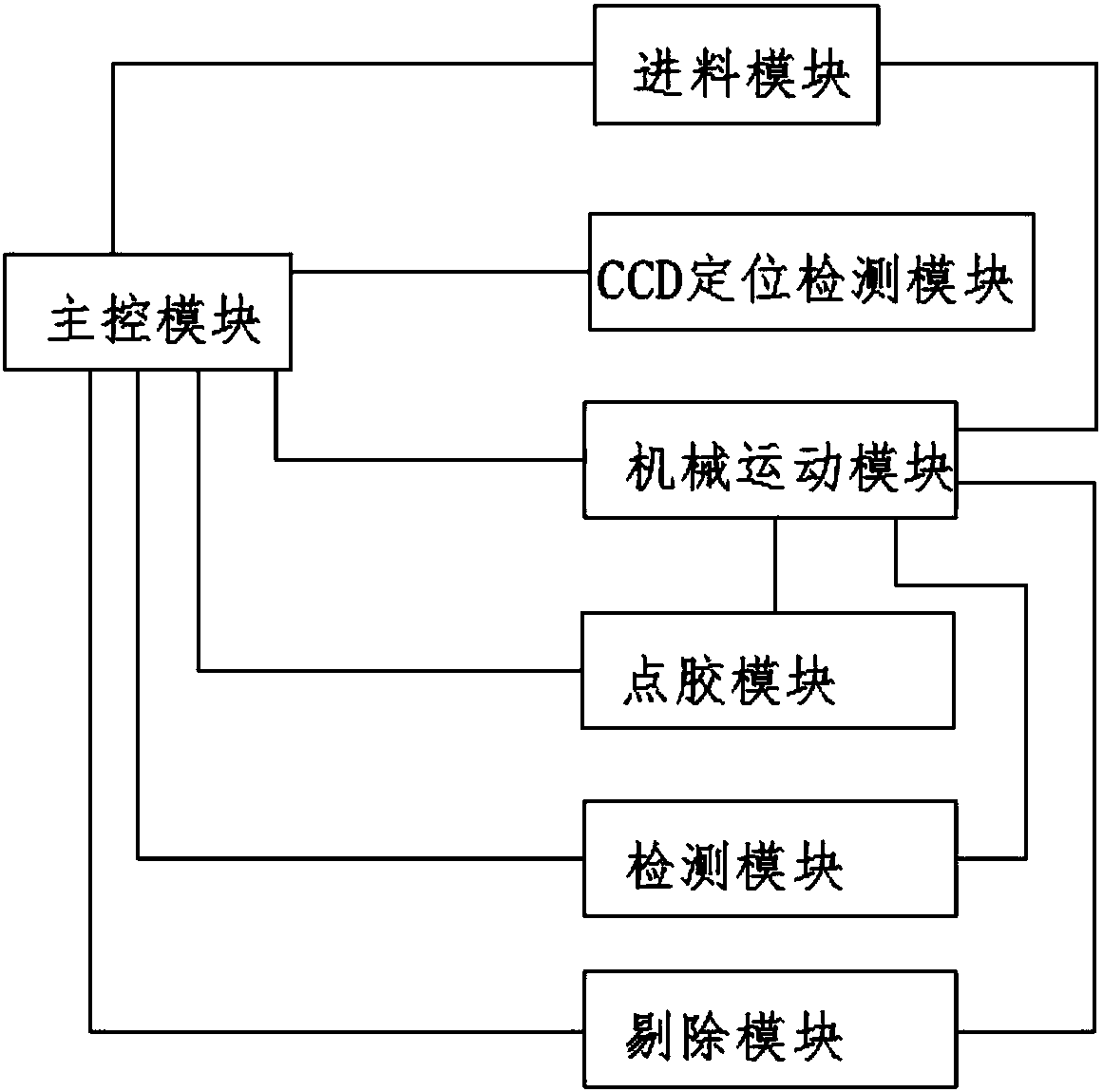

[0026] An online automatic dispensing machine, comprising: a main control module and a feeding module connected to the main control module and controlled by the main control module, a CCD positioning detection module, a mechanical movement module, a dispensing module, a detection module, and a rejection module, Among them, the feeding module, glue dispensing module, rejecting module and detection module are all connected with the mechanical movement module and moved to the target position with the assistance of the mechanical movement module. The unit is a human-computer interaction interface, and the screening unit is equipped with a scrap selection box and a glue filling selection box that can be manually clicked and selected. Among them, the glue filling selection box includes a writing box for limiting the number of missing glue spots. When the detected missing glue quantity does not exceed the limit value, the main control module will send a glue filling signal, otherwise ...

specific Embodiment 2

[0037] An online automatic dispensing machine, comprising: a main control module and a feeding module connected to the main control module and controlled by the main control module, a CCD positioning detection module, a mechanical movement module, a dispensing module, a detection module, and a rejection module, Among them, the feeding module, glue dispensing module, rejecting module and detection module are all connected with the mechanical movement module and moved to the target position with the assistance of the mechanical movement module. The unit is a human-computer interaction interface, and the screening unit is equipped with a scrap selection box and a glue filling selection box that can be manually clicked and selected. Among them, the glue filling selection box includes a writing box for limiting the number of missing glue spots. When the detected missing glue quantity does not exceed the limit value, the main control module will send a glue filling signal, otherwise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com