Working table with dust remover

A workbench and dust collector technology, which is applied in the direction of workbench, dust removal, and tool manufacturing, can solve the problems of poor shock absorption effect of the workbench, high noise, inconvenient installation and fixing of fans, etc., and achieves simple structure, reduced noise, Easy to absorb shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

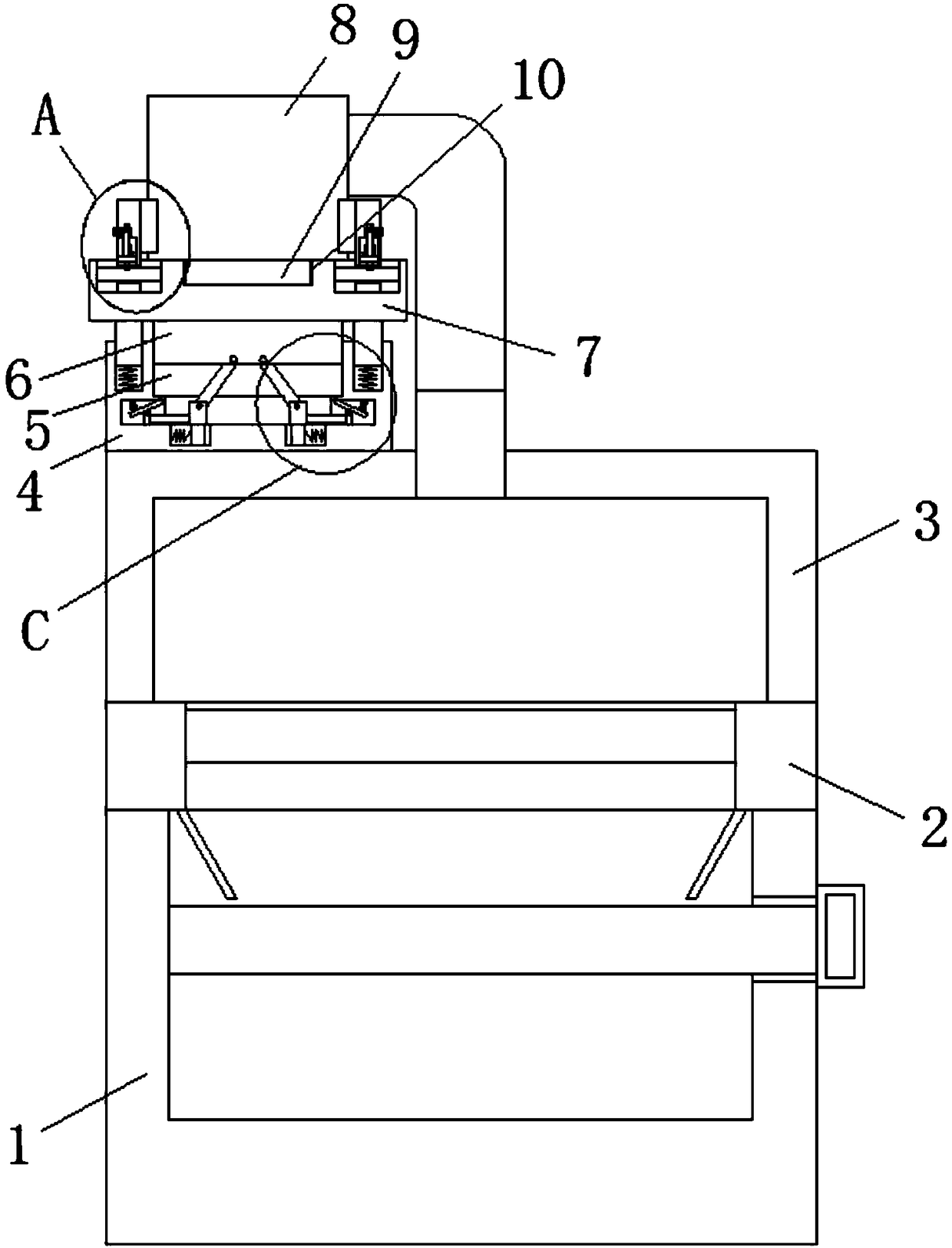

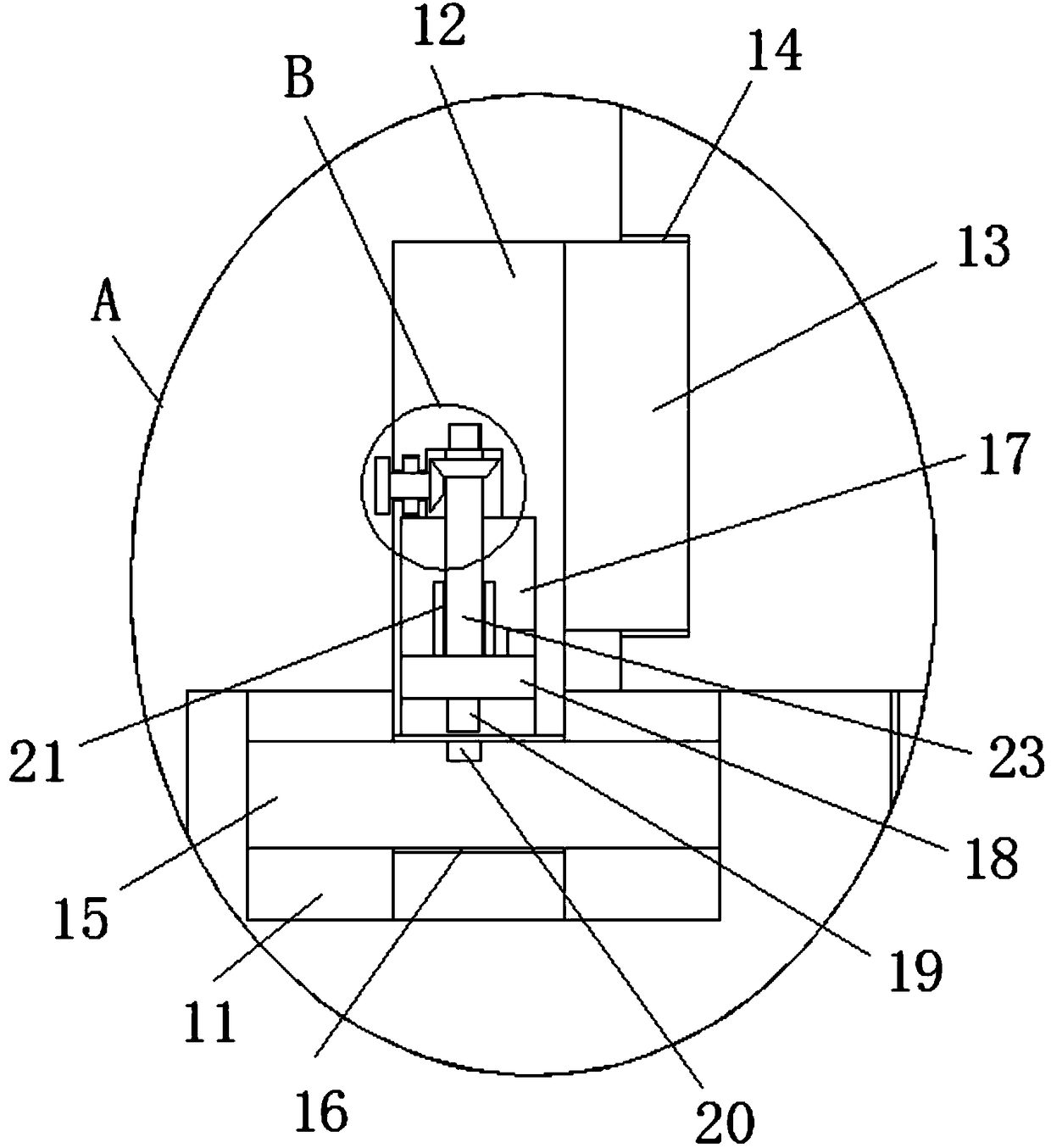

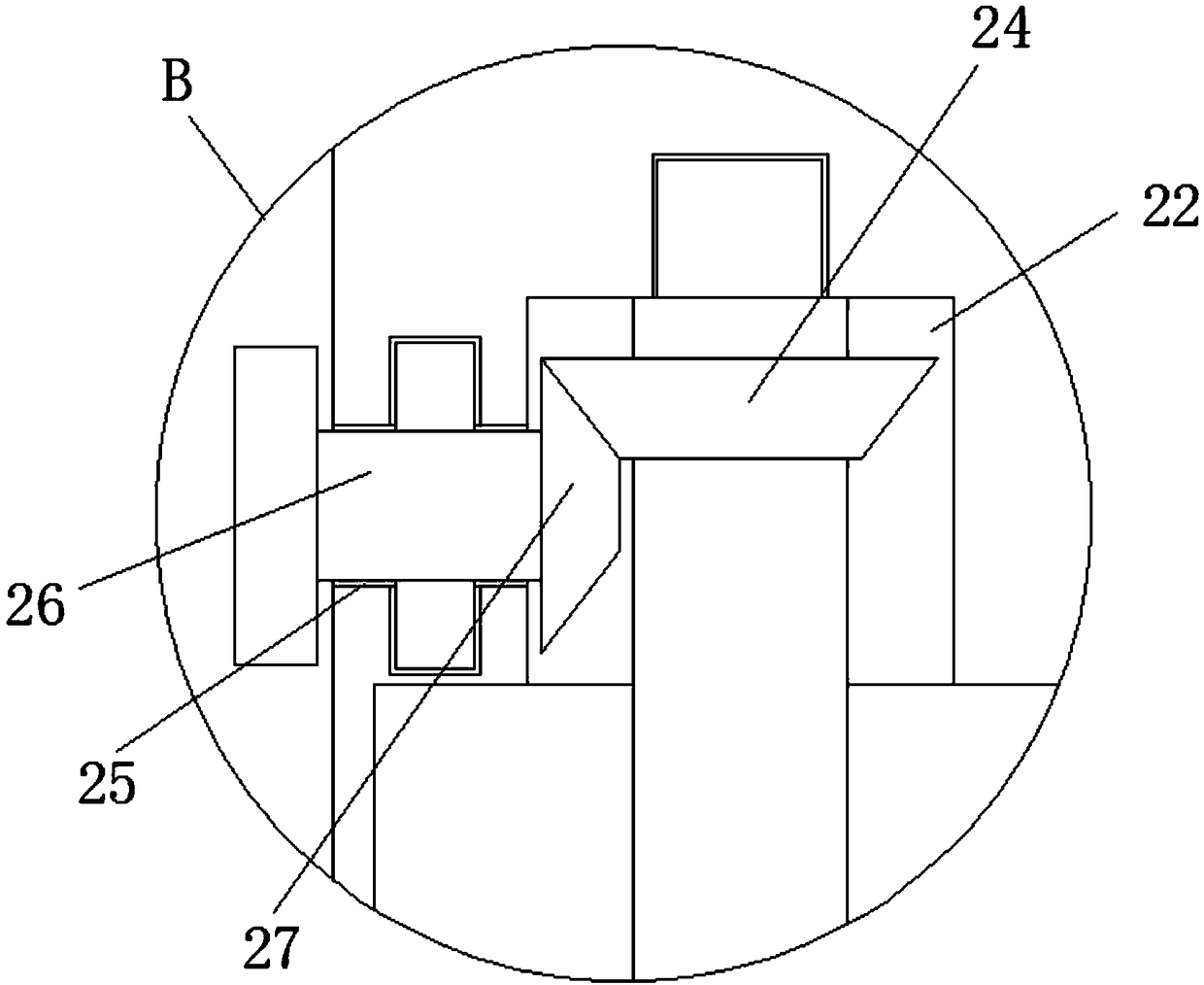

[0028] refer to Figure 1-5In this embodiment, a workbench with a dust collector is proposed, which includes a bottom box 1 with an opening at the top, and an operating platform 2 is fixedly installed on the top of the bottom box 1, and the operating platform 2 covers the opening of the bottom box 1. The top of the console 2 is fixedly installed with an installation box 3 with openings on the bottom and one side. The top of the installation box 3 is fixed with an installation plate 4. The top of the installation plate 4 is provided with a buffer groove 5, and the buffer groove 5 is slidingly installed with Buffer plate 6, the top of buffer plate 6 is fixedly installed with the placement plate 7 that is positioned at the top of mounting plate 4, fan 8 is placed on the top of placement plate 7, and the bottom of fan 8 is fixedly installed with placement block 9, and the top of placement plate 7 is provided with The placement slot 10, the placement block 9 and the placement slot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com