Sunken concrete mixing plant

A mixing station and concrete technology, applied in mixing plants, clay preparation devices, mixing operation control, etc., can solve the constraints of concrete mixing plant production capacity, popularization rate and regionality, unfavorable energy saving and emission reduction, reduce enterprise energy consumption, dust, Problems such as noise and vibration are difficult to isolate, so as to improve land use efficiency, facilitate dust collection, and shorten transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

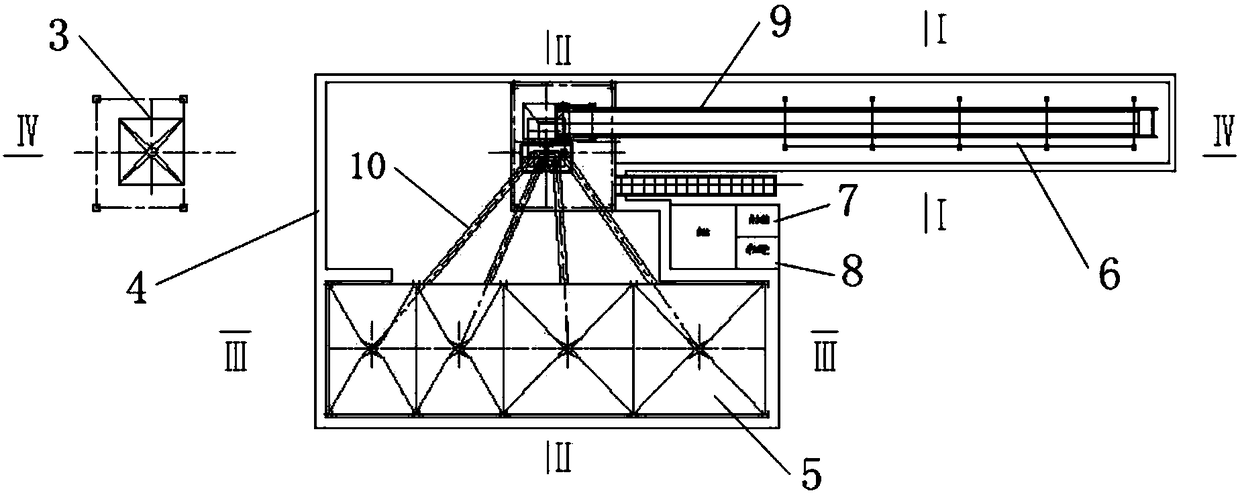

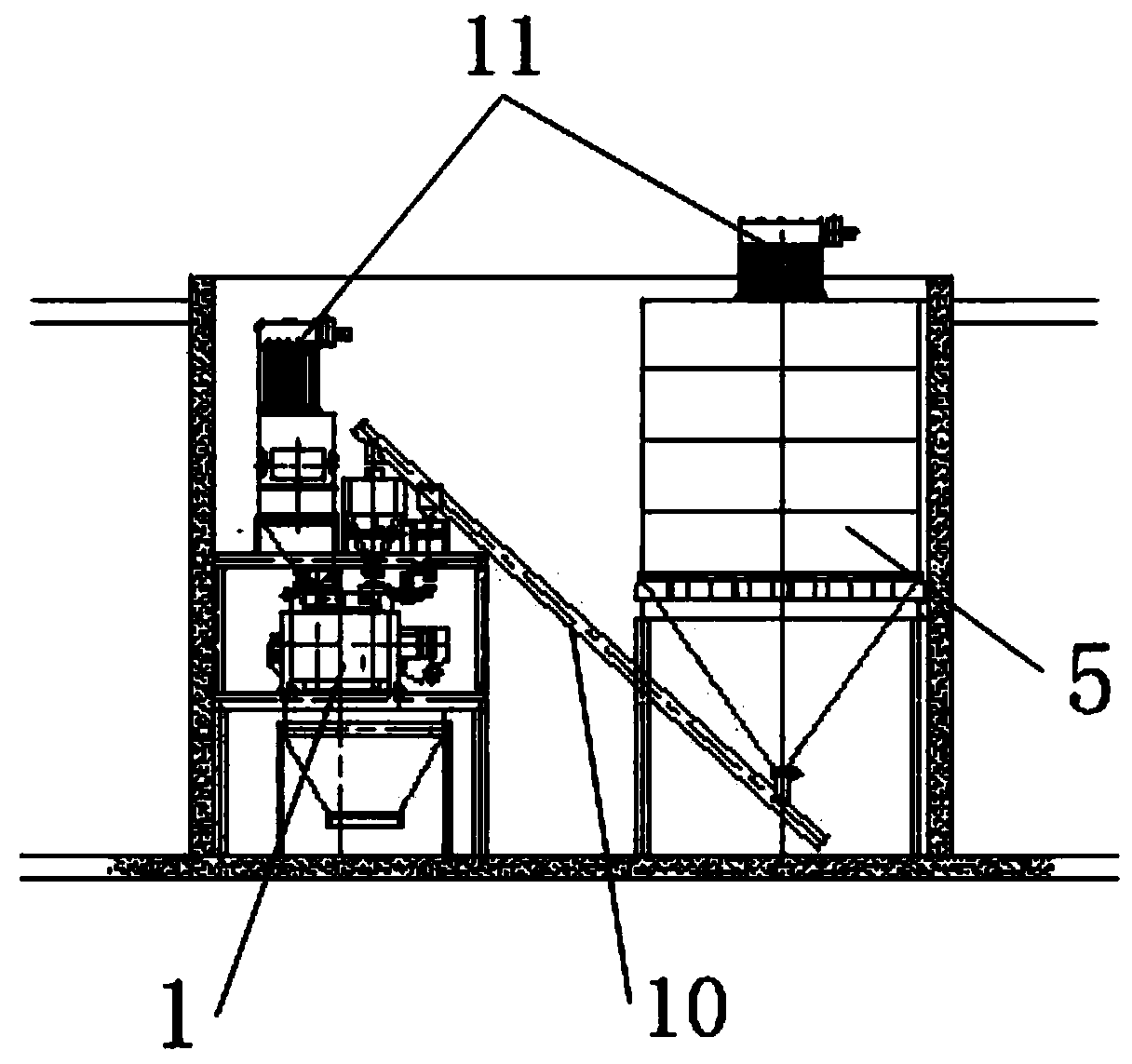

[0026] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

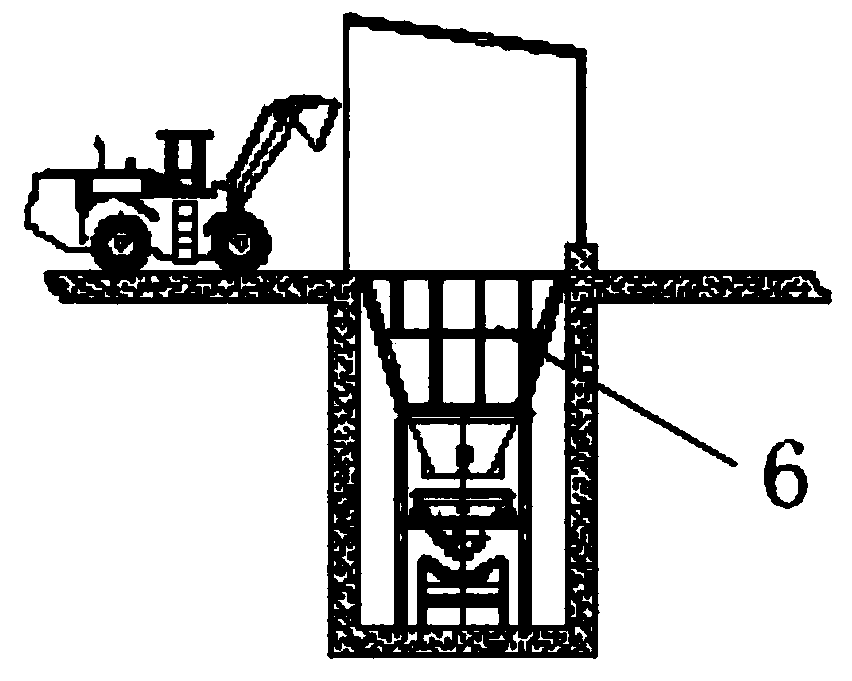

[0027] As shown in the figure, the present invention provides the following technical solutions: a sunken concrete mixing plant, including a storage system for storing materials, a mixing device 1 and a control system, and also includes a material lifting system 2 and a discharge device 3, so that The storage system and the stirring device 1 are arranged in the pit 4 below the ground, the control system and the unloading device 3 are arranged on the ground, and the stirring device 1 is connected to the unloading device 3 through the material lifting system 2 .

[0028] In this embodiment, the control system and the unloading device 3 are set on the ground, and the operator can control the lower operation through the monitoring system set in the pit and the control system on the ground without entering the pit, which improves the safety of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap