Trolley capable of achieving mold replacement by automatic operation

A technology for mold replacement and automatic operation, applied in the field of transport vehicles, which can solve the problems of large space area, long interval between adjacent molds, and high cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

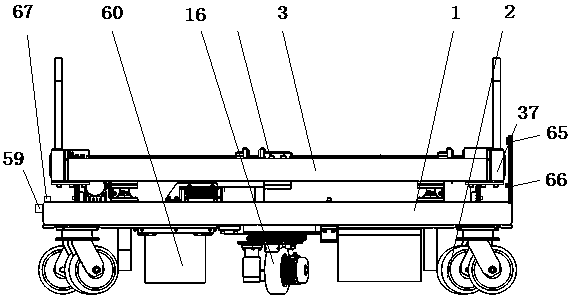

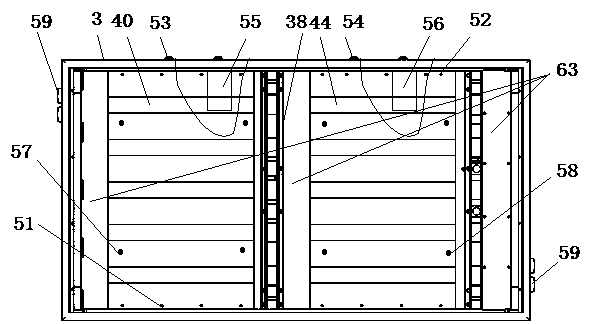

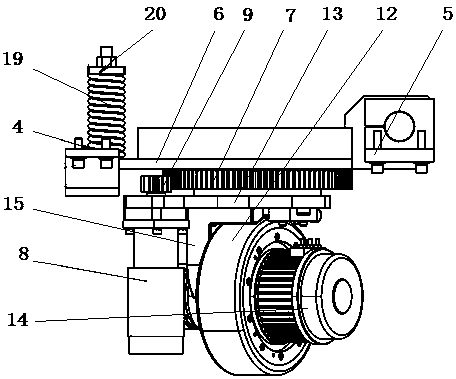

[0049] As shown in the accompanying drawings, a trolley that automatically runs and replaces molds includes a car body 1. Four universal wheels 2 are provided at the lower end of the car body 1. It is characterized in that the centers on both sides of the lower end of the car body 1 are respectively provided with There is a driving traveling device 16, the upper end of which is provided with an exchange workbench 3, the car body 1 is provided with a PLC control system 17 and a power supply 18, and the power supply supplies power for the PLC control system, and the driving traveling device includes a front positioning frame 4, Rear positioning frame 5, rotating bracket 6, slewing bearing with outer ring gear 7, rotating motor 8, driving pinion 9, driven pinion 10, driving traveling wheel 11, driving shaft 12, driving wheel bracket 13, traveling motor 14 And the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com