Yarn cutting driving structure

A driving structure and yarn cutting technology, which is applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of high production cost, difficulty in production and assembly, and economical reduction, so as to improve product economy and practicability, The effect of simplifying the internal structure and production process, reducing weight and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

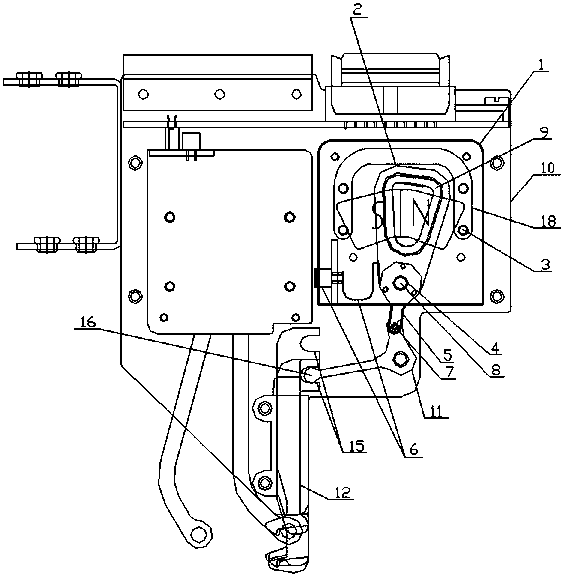

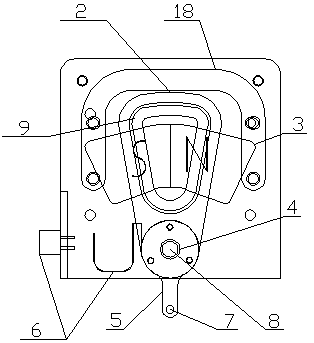

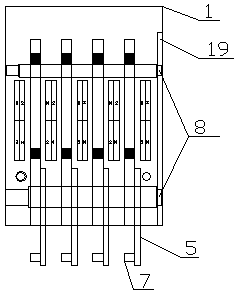

[0036] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , a yarn cutting driving structure, including a yarn clamping and cutting device 12 and a driver housing 1 respectively arranged on the outer plate 10 of the thread changer, a yarn cutting lever 11 is installed on the outer plate 10 of the thread changer through a rotating shaft 8, and the yarn clamping Both the auxiliary yarn cutter 13 and the yarn pressing plate 14 of the yarn cutting device 12 are provided with a groove 15, and the yarn cutting lever 11 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com