Special device for down ball preparation and down ball preparation method thereof

A special device, the technology of down balls, is applied in textiles, papermaking, fiber processing, etc. It can solve problems such as troublesome production process, affecting thermal performance, uneven down, etc., and achieves the effect of simple preparation method and convenient filling of down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a down ball. The preparation of the down ball is completed through the steps of pretreatment of the down, compression of the down, preparation of a water-soluble adhesive, wrapping of the down, shaping and drying of the down ball; the specific steps are as follows:

[0031] (1) Down pre-treatment: wash the down, soak the washed down in alkaline water, heat and cook, then air-dry for later use, the soaking time in alkaline water is 60-66h, and the cooking temperature is 120-140°C ;

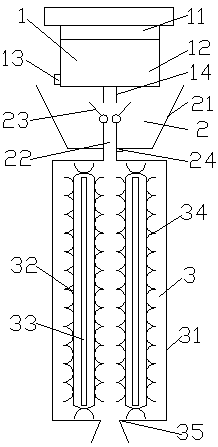

[0032] (2) Down compression: place the air-dried down in the compression groove 12 of the special device for preparing down balls, compress the down through the cylinder 11, and then discharge it through the outlet a14;

[0033] (3) Preparation of water-soluble adhesive: prepared from polyacrylamide, formaldehyde, dibutyl phthalate, polyethylene glycol, polyvinyl formal, high-energy refined fish oil, hydrochloric acid and deionized water, specifically The mass percent...

Embodiment 1

[0038] A method for preparing a down ball. The preparation of the down ball is completed through the steps of pretreatment of the down, compression of the down, preparation of a water-soluble adhesive, wrapping of the down, shaping and drying of the down ball; the specific steps are as follows:

[0039] (1) Down pretreatment: wash the down, soak the washed down in alkaline water, heat and cook, and then air-dry for use. The soaking time in alkaline water is 60 hours, and the cooking temperature is 120°C;

[0040] (2) Down compression: place the air-dried down in the compression groove 12 of the special device for preparing down balls, compress the down through the cylinder 11, and then discharge it through the outlet a14;

[0041] (3) Preparation of water-soluble adhesive: prepared from polyacrylamide, formaldehyde, dibutyl phthalate, polyethylene glycol, polyvinyl formal, high-energy refined fish oil, hydrochloric acid and deionized water, specifically The mass percentage is 10...

Embodiment 2

[0046] A method for preparing a down ball. The preparation of the down ball is completed through the steps of pretreatment of the down, compression of the down, preparation of a water-soluble adhesive, wrapping of the down, shaping and drying of the down ball; the specific steps are as follows:

[0047] (1) Down pretreatment: wash the down, soak the washed down in alkaline water, heat and cook, and then air-dry for use. The soaking time in alkaline water is 66 hours, and the cooking temperature is 140°C;

[0048] (2) Down compression: place the air-dried down in the compression groove 12 of the special device for preparing down balls, compress the down through the cylinder 11, and then discharge it through the outlet a14;

[0049] (3) Preparation of water-soluble adhesive: prepared from polyacrylamide, formaldehyde, dibutyl phthalate, polyethylene glycol, polyvinyl formal, high-energy refined fish oil, hydrochloric acid and deionized water, specifically The mass percentage is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com