Deep and large open caisson prefabricated structure and mounting method thereof

A technology of prefabricated structures and installation methods, which is applied in infrastructure engineering, caissons, protective devices, etc., can solve problems such as locking and difficulty in controlling the construction period, and achieve the effects of shortening the construction period, reducing costs, and simple principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

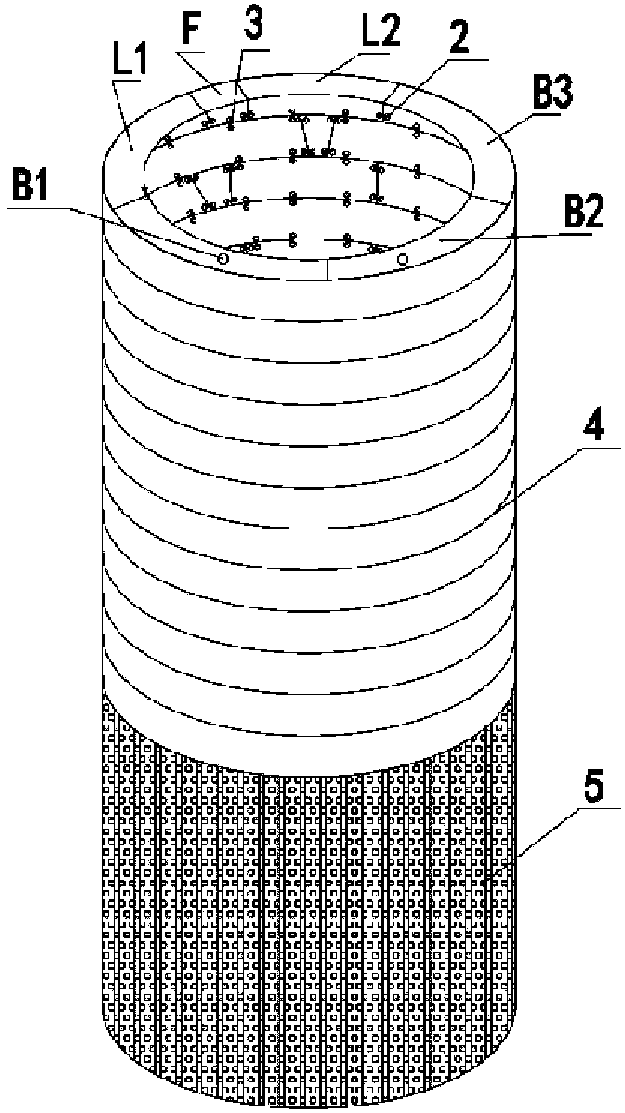

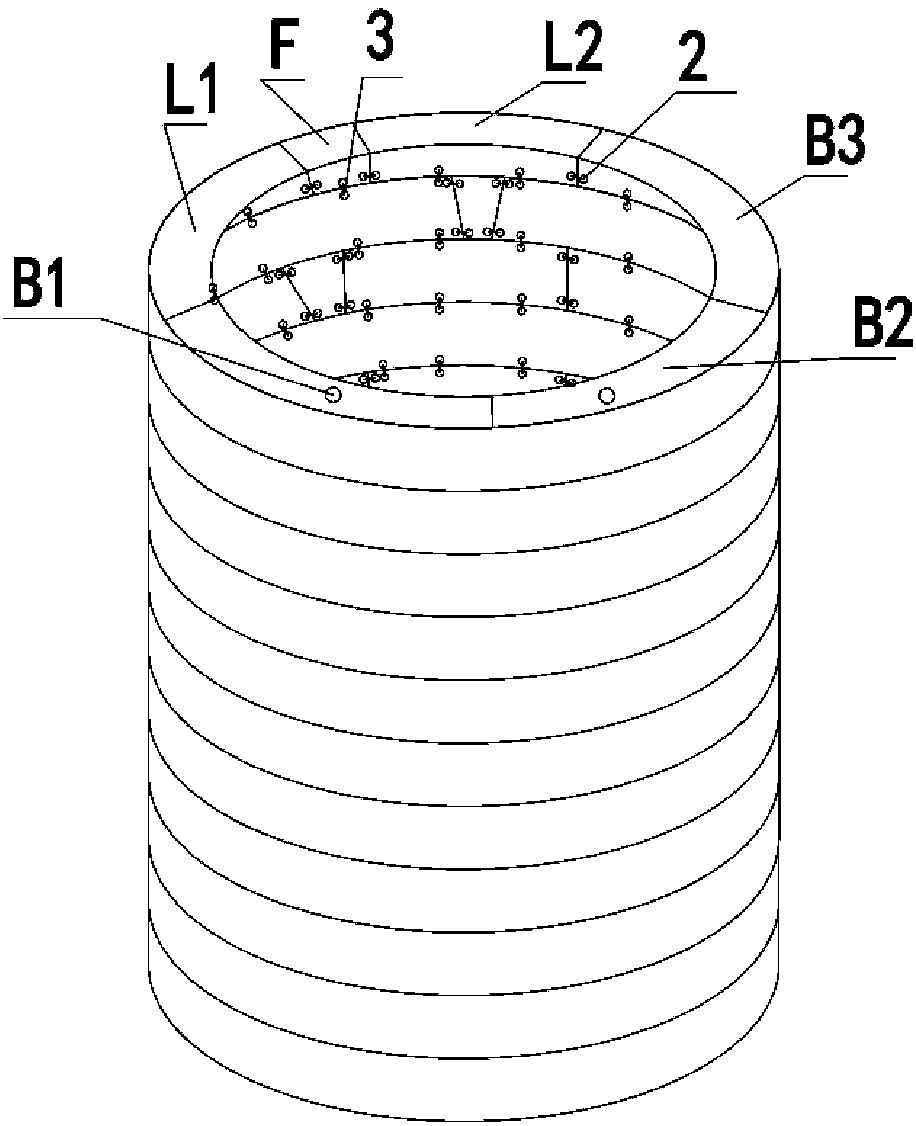

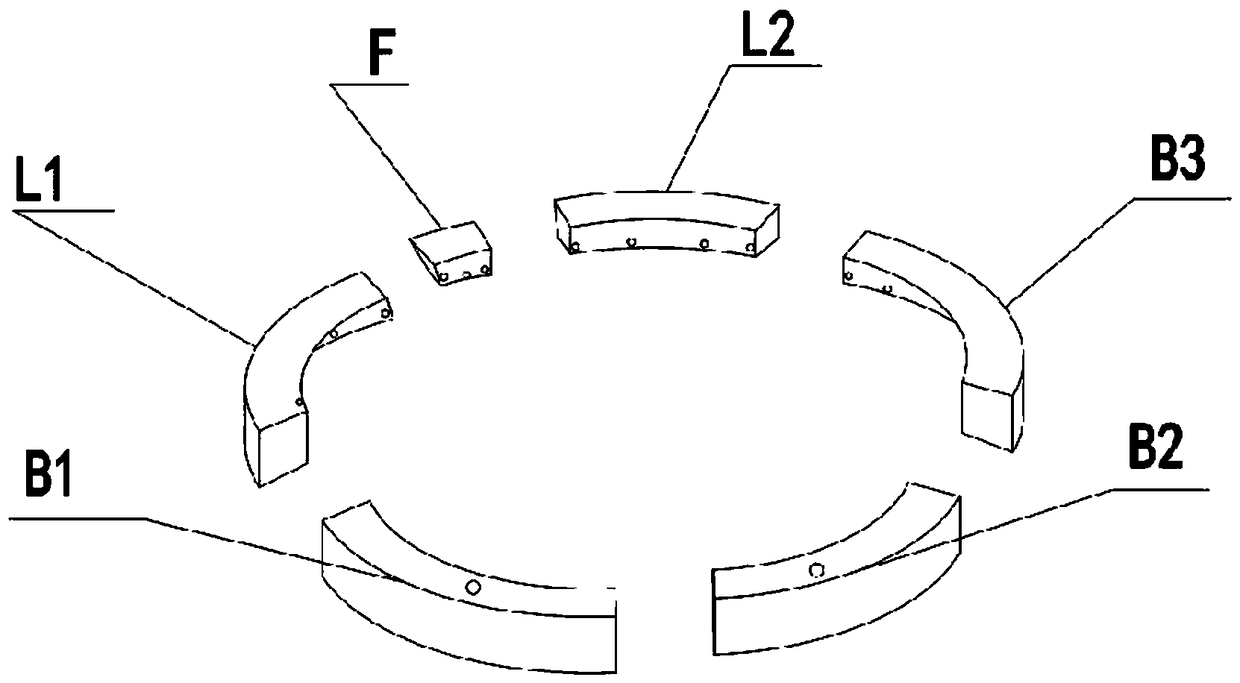

[0054] According to the attached Figure 1~9 Technical method of the present invention is described further:

[0055] This device has been successfully applied to the construction practice of the drainage pipe network improvement project in the north of Kunming main city, which improves work efficiency, saves materials, ensures quality, is safe and reliable, and has high application and promotion value. Among them, the concrete strength grade of blade foot 5 is C40, and the impermeability grade is P8. The prefabricated ring piece is a double-sided wedge-shaped universal ring with a wedge shape of 113.54 mm. The prefabricated ring piece is composed of wedge-shaped block F, adjacent block IL1, adjacent block IIL2, standard block IB1, standard block IIB2, and standard block IIIB3. The wedge-shaped block F , adjacent block IL1, adjacent block IIL2, standard block IB1, standard block IIB2, and standard block IIIB3 are provided with two pairs of circumferentially curved bolt tunnel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com