Compressor with segmented inner shroud for an axial turbine engine

A turbine engine, engine technology, applied in the direction of engine cooling, engine lubrication, components of pumping devices for elastic fluids, etc., can solve the problems of complex layout, leakage, increased geometric structure restrictions of rectifier non-uniformity, etc., To achieve the effect of output optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

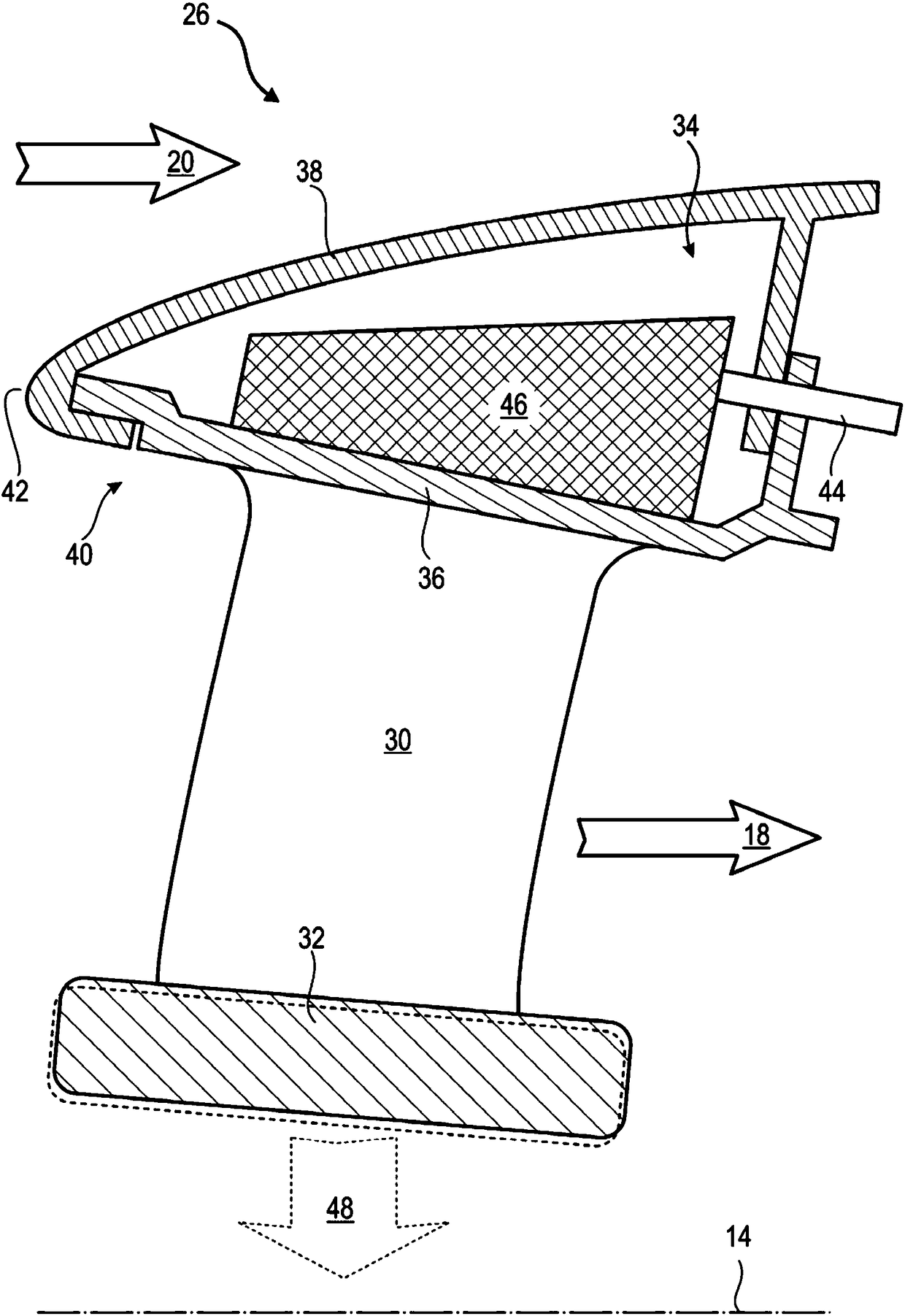

[0044] It should be clearly understood that the invention proposes a turbojet engine with a fan driven by a drive forming a heat source whose heat affects the circumference between the segments of the inner shroud via a cooling and / or lubrication circuit. To the size of the gap, the inner shroud is attached to the stator blades.

[0045] In the following description, the terms "inner" and "outer" refer to an orientation relative to the axis of rotation of the axial turbine engine. Axial corresponds to a direction along the axis of rotation of the turbine engine. Radial is perpendicular to the axis of rotation. Upstream and downstream refer to the main flow directions of flow in a turbine engine.

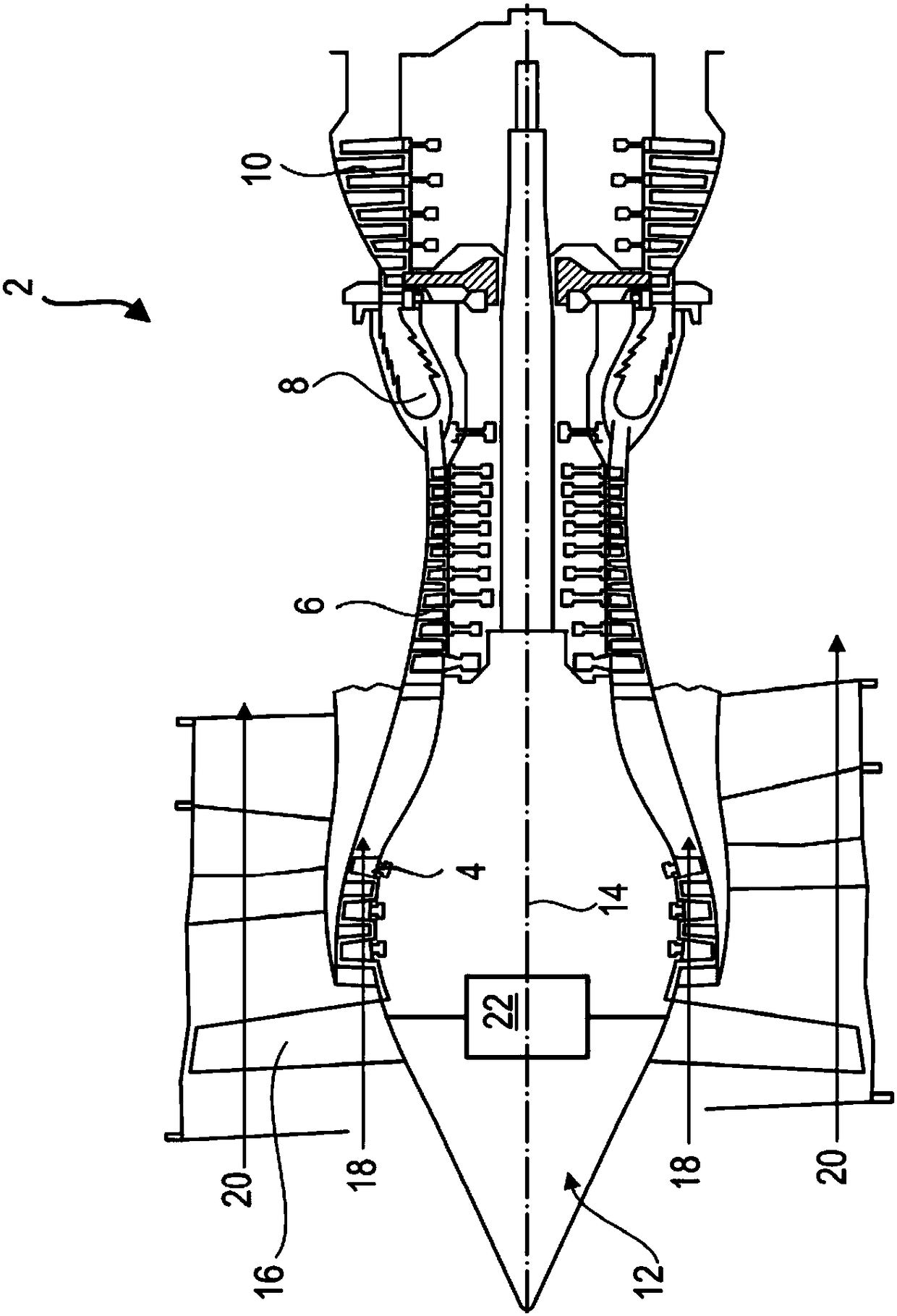

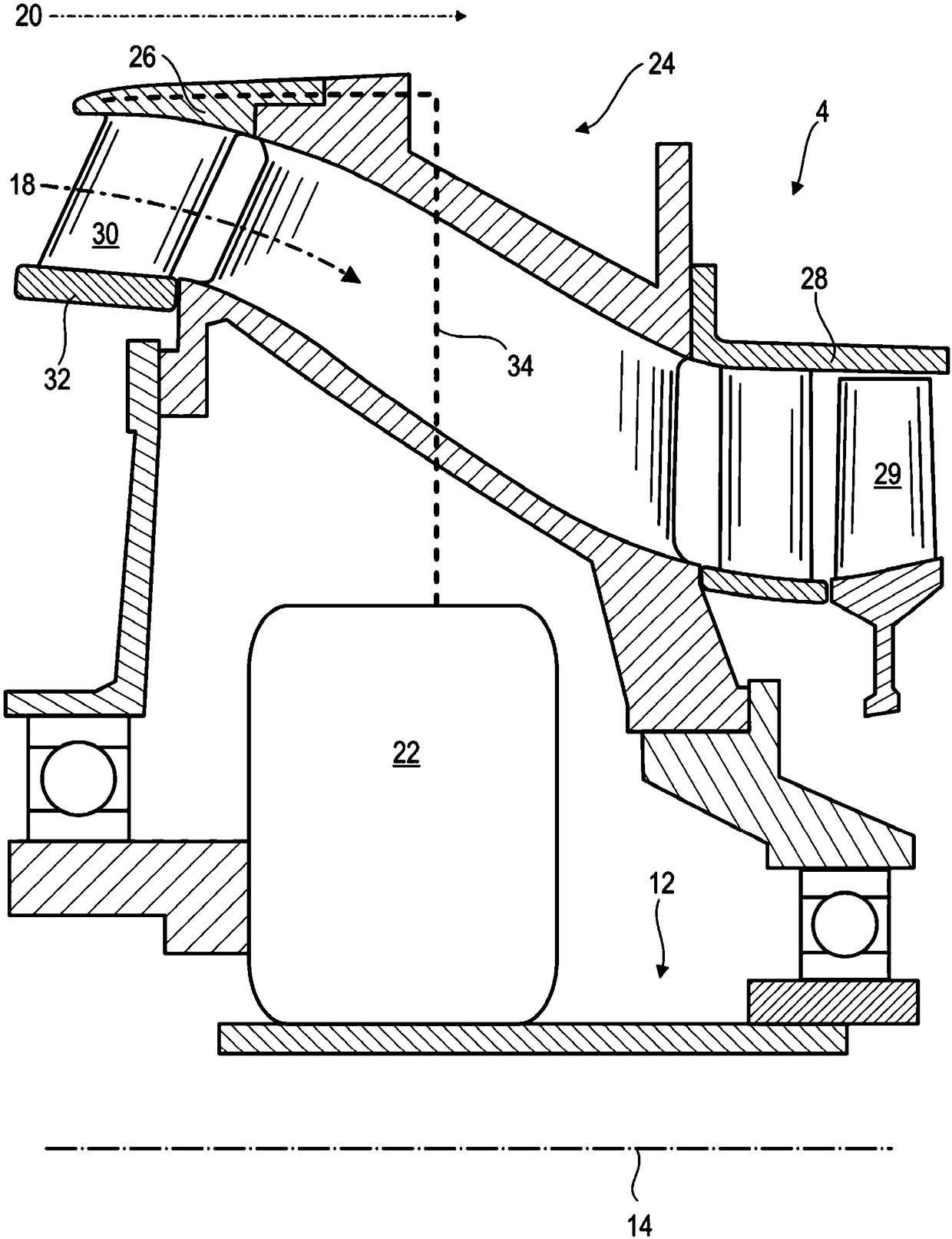

[0046] figure 1 An axial turbine engine 2 is shown in a simplified manner. In this particular case it is a dual flow turbo jet engine. The turbojet engine comprises a first compression stage called low-pressure compressor 4 , a second compression stage called high-pressure compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com