Construction technology of municipal pipeline maintenance

A construction technology and municipal pipeline technology, applied in the field of municipal pipeline construction, can solve problems such as lowering work efficiency, damage to traction devices, blocking, etc., and achieve the effect of improving work efficiency and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

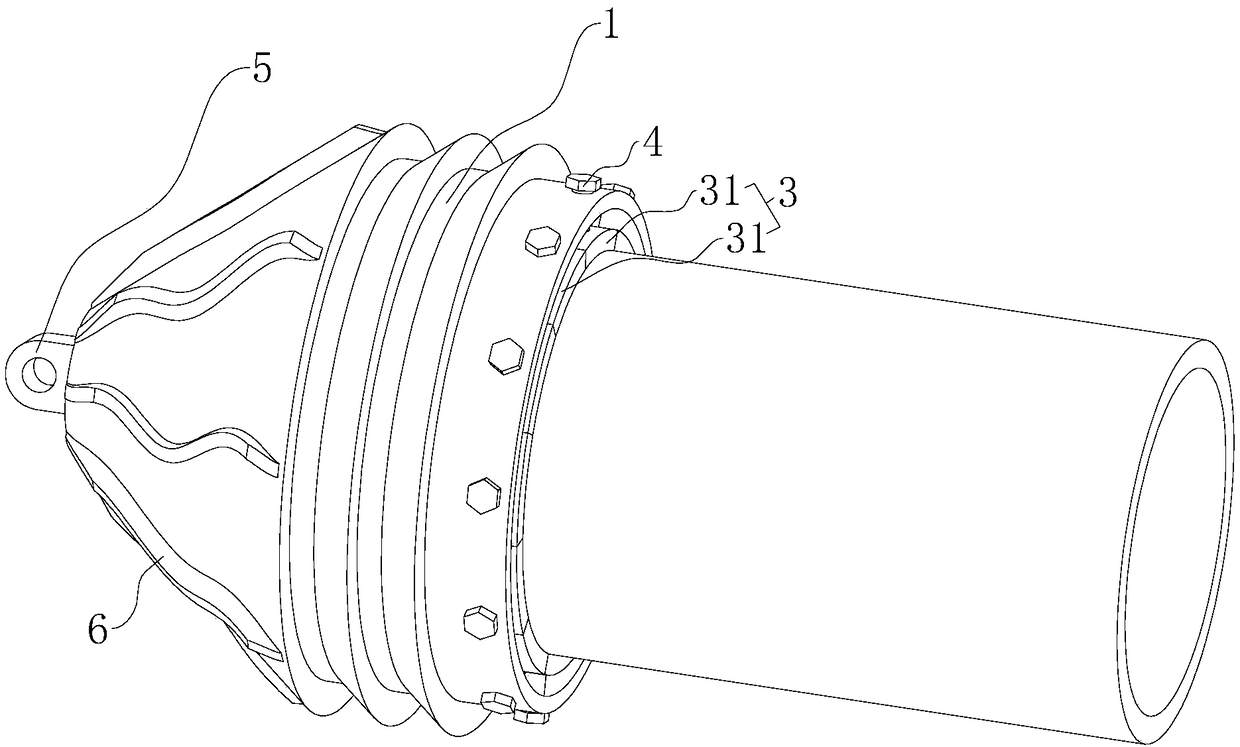

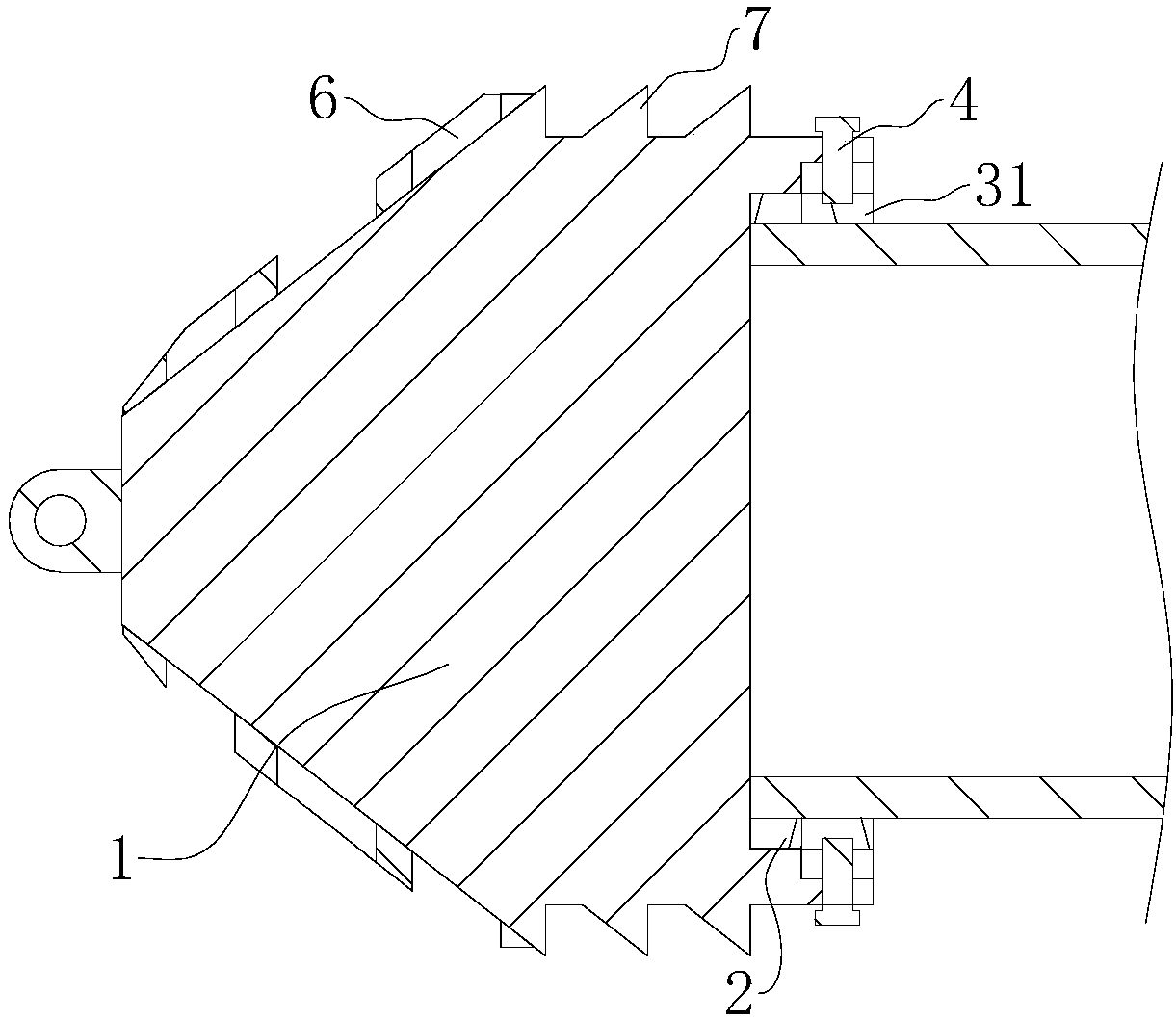

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0047] A construction process for municipal pipeline maintenance, comprising the steps of:

[0048] S1. On-site survey, plan according to the original pipeline trajectory; block the nearest drainage wells on both sides of the damaged pipeline, and cut off the drainage in the repaired pipeline area.

[0049] S2. Excavating working pits: Dig a digging working pit and an excavating working pit at the positions of the guiding entry and exit points. The guiding entry pit is 2.5 meters deep, 6 meters long and 1.5 meters wide, and the excavation pit is 2.5 meters deep. The chute is 6 meters long and 1.5 meters wide; it is convenient for the mud to be discharged from the storage and the pipeline to be dragged back.

[0050] S3, pilot hole drilling

[0051] a. Safety enclosure of the construction area

[0052] b. Deep well dewatering, two deep well dewatering shall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com