Continuous type transonic wind tunnel semi-flexible wall jet tube guide rail horizontal throat block driving device

A drive device, transonic technology, applied in the field of horizontal throat block drive device of semi-flexible wall nozzle guide rail, can solve the problems of inability to provide throat block and inconvenience, and achieve convenient mechanism maintenance, large driving force and long-term stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

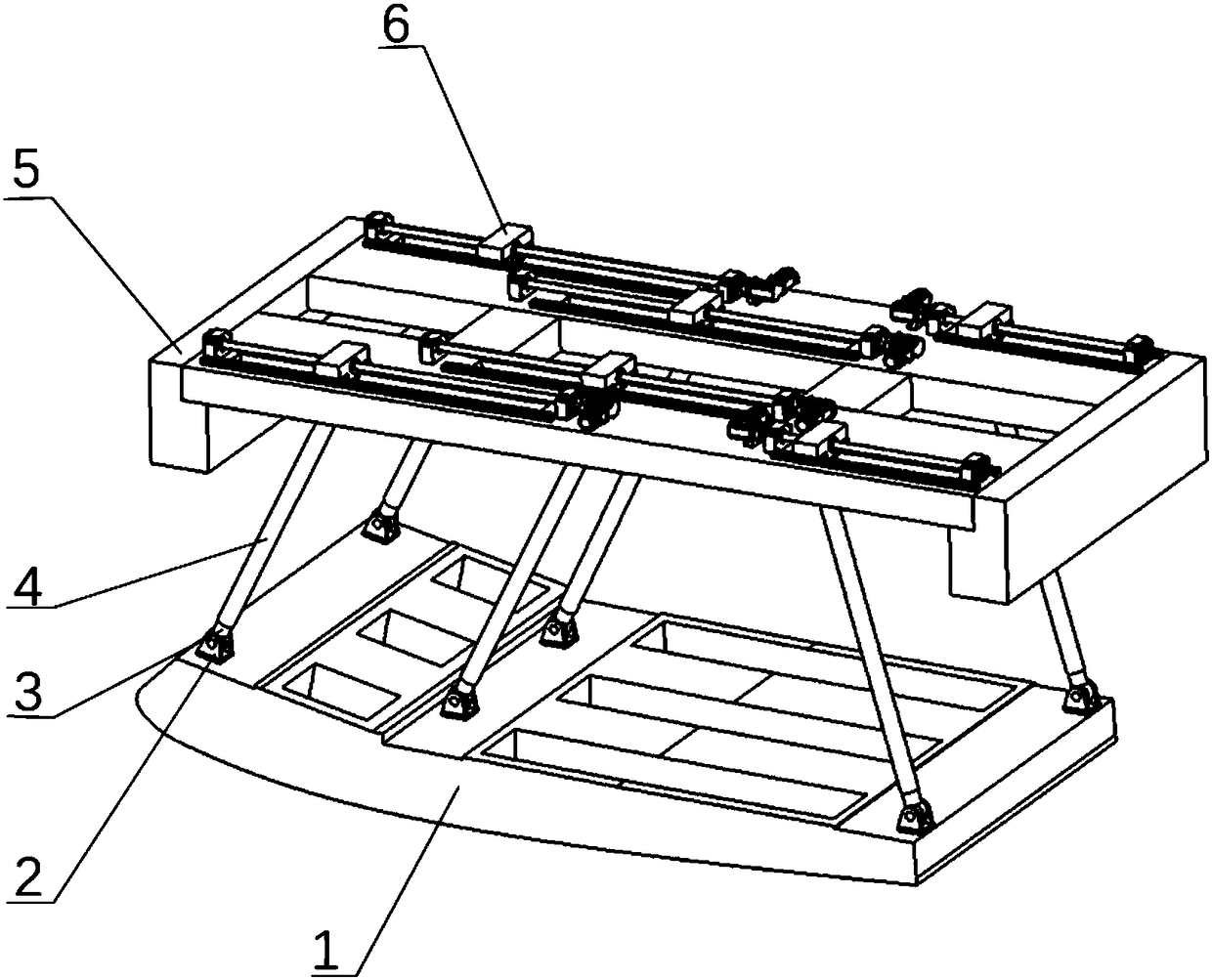

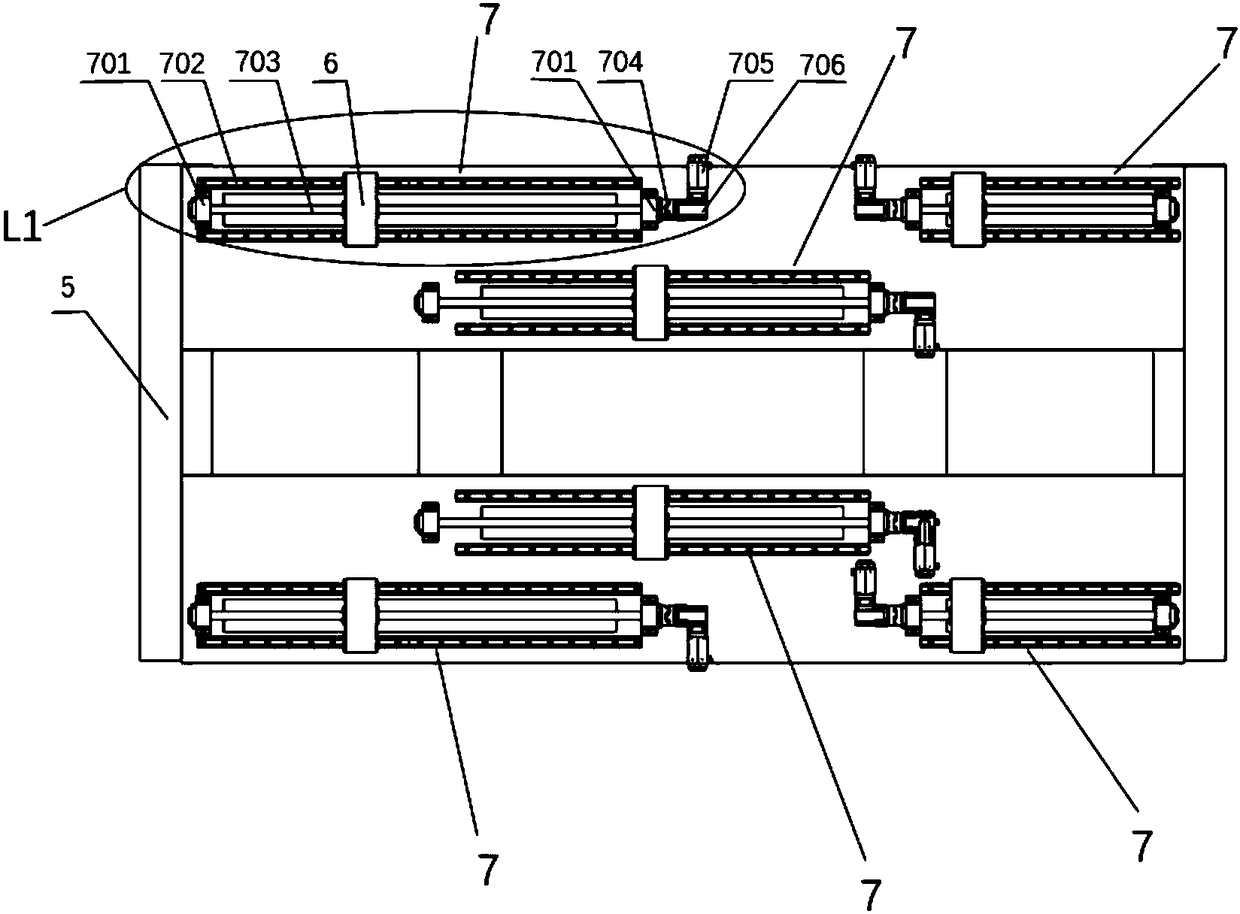

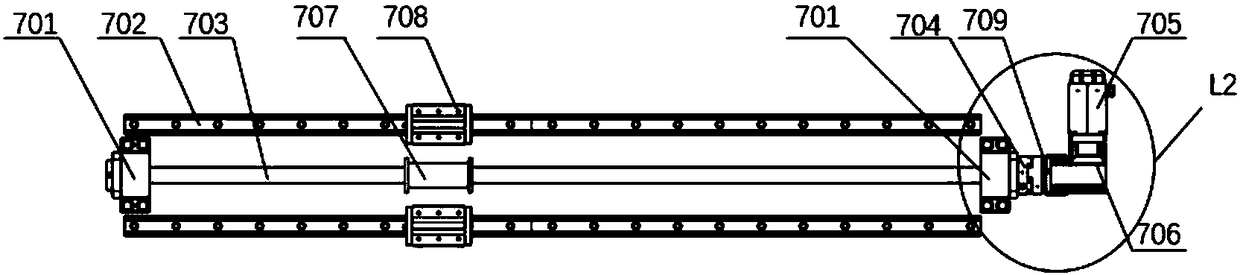

[0028]The support platform (5) is a flat plate with slots placed horizontally, used for installing and precisely positioning the guide rail (702), and can fully bear the force of the guide rail (702) on it during work. Good rigidity is ensured by designing its structure, which will ensure the pose forming accuracy of the final throat block (1). Several drive units (7) are housed on the support platform (5), and each drive unit (7) includes: a servo motor (705) is connected with a right-angle reducer (706) to reduce the output speed of the motor, and the servo motor (705 ) and the reducer (706) are horizontally installed on the support platform (5) through the reducer support (709); Lead screw (703) is installed on the top of support platform (5) by lead screw support (701), the output of reducer (706) drives lead screw (703) to rotate through coupling (704), lead screw nut (707 ) converts the rotation of the leading screw (703) into linear motion in the horizontal direction. ...

Embodiment 2

[0030] The main structure of this embodiment is the same as that of Embodiment 1. Furthermore, in addition to bearing the weight of each component, the semi-flexible throat block of the nozzle section of the large-scale continuous transonic wind tunnel also needs to consider the complex and variable aerodynamic load. It is necessary to judge the layout of the guide rail slider according to the force of the specific mechanism. It is a double guide rail double slider arrangement or a multi guide rail multi slider arrangement, so as to ensure that the force is within the bearing range of the guide rail slider and make the guide rail slider normal. operation, and to ensure that it has a certain service life.

Embodiment 3

[0032] The main structure of this embodiment is the same as that of Embodiment 1. Furthermore, since the semi-flexible guide rail horizontal throat block driving device of the continuous transonic wind tunnel nozzle section will be subjected to lateral force, the guide rail horizontal throat block driving device is designed as A six-degree-of-freedom mechanism is used to obtain the ability to actively resist lateral forces, so the rotating hinge can choose a spherical hinge. However, since the displacement of the throat block in the longitudinal direction is very small, the space pose of the throat block is less than 5° at the lateral inclination angle, and since the joint bearing can rotate in three directions at a small angle, the joint bearing can also be used for the rotary hinge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com