Multifunctional box type detachable rotational flow distortion generator

A technology of distortion generator and swirl distortion, which is applied in the field of aero-engines, can solve the problems of time-consuming and laborious installation and calibration, and high processing costs, and achieve the effect of reducing manpower and technology, multiple forms of swirl distortion, and fine adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following specifically explains the embodiments of the present invention.

[0026] The present invention will be further explained below with reference to the drawings and examples.

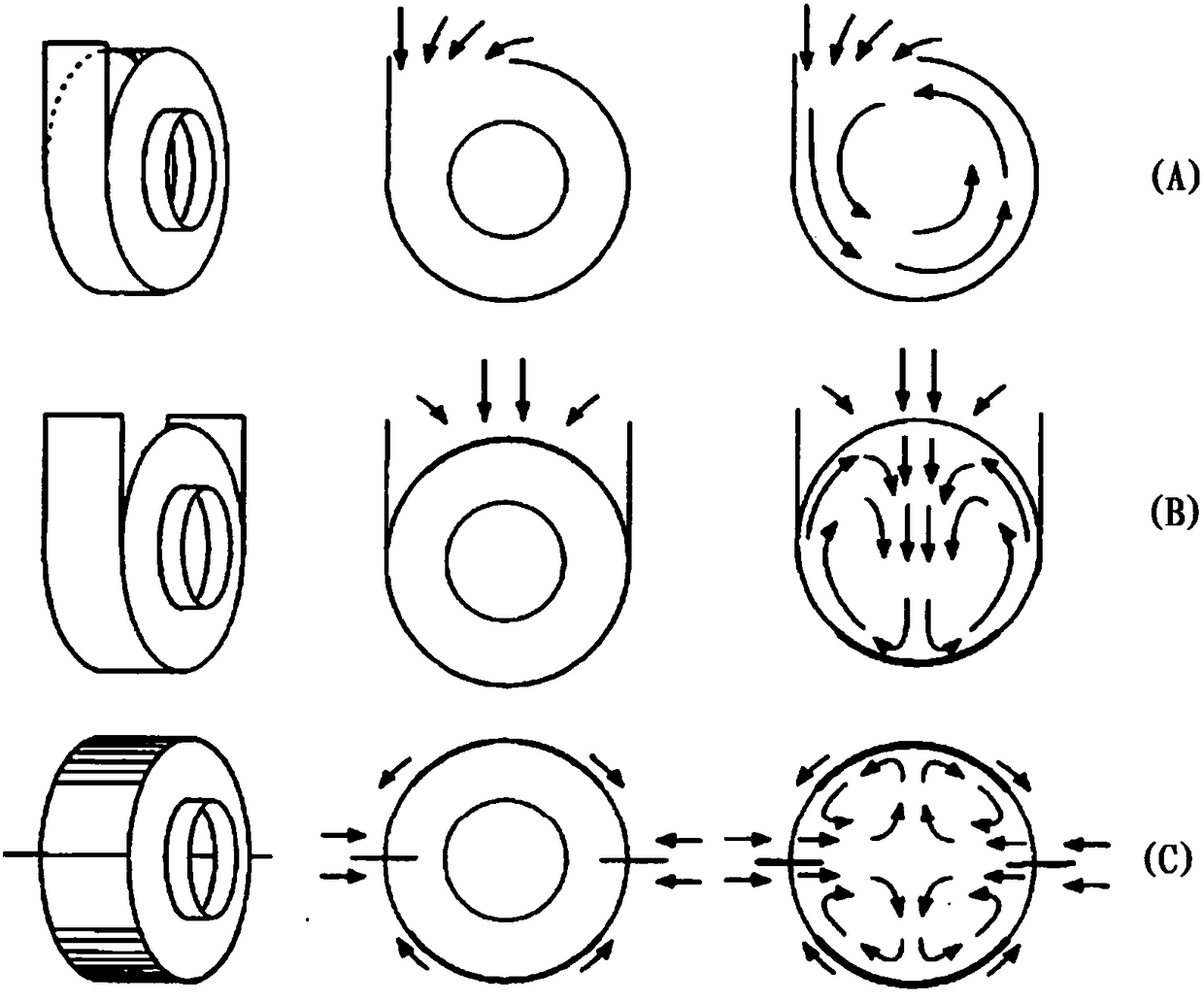

[0027] figure 1 The aerodynamic principle diagrams generated by three typical swirling distortions are shown in. The principle of the universal swirling distortion generator of the present invention is correct and feasible, and it can meet different forms of swirling distortion simulation, and the intensity of single swirling flow reaches 40° , The intensity of the vortex flow reaches 20°, and the distortion of the multi-vortex flow can reach about 10°.

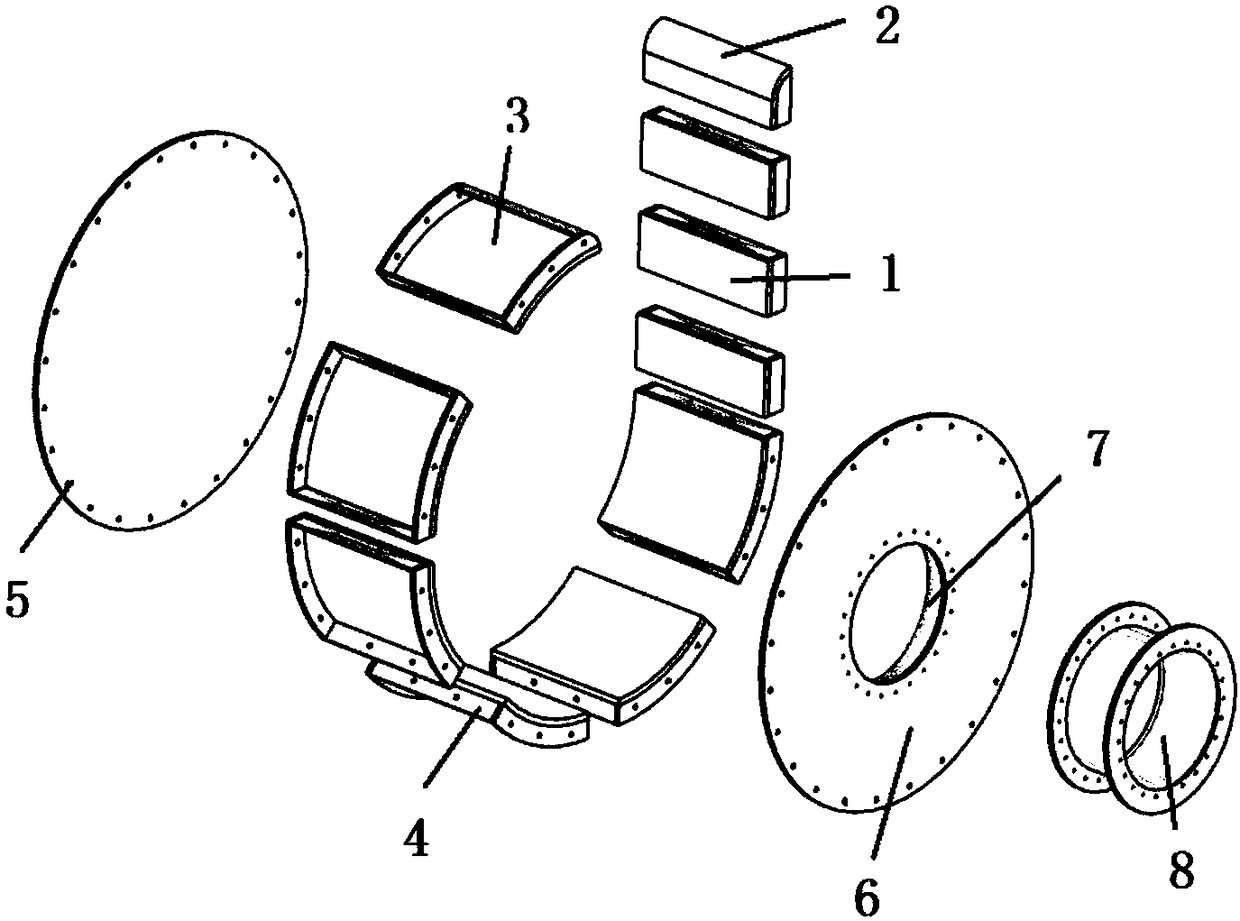

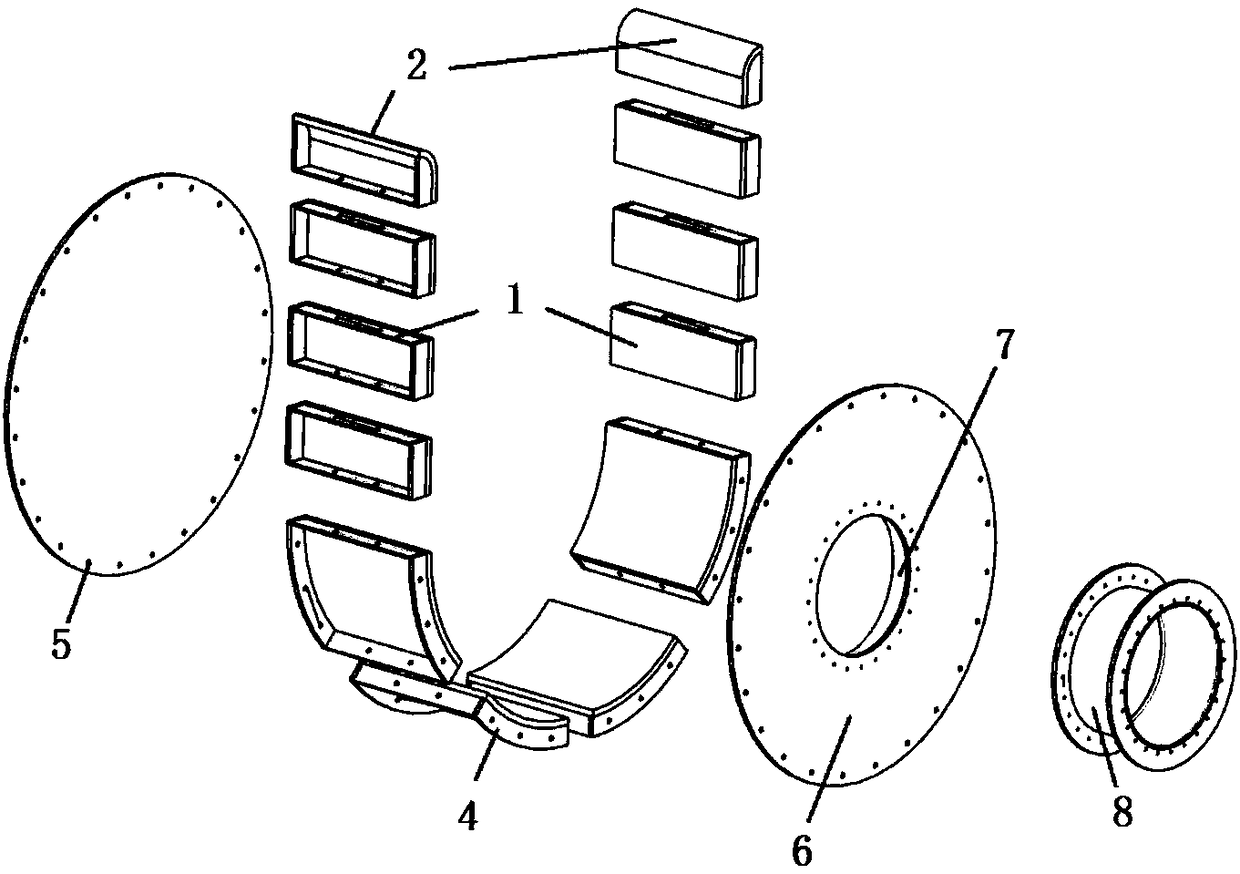

[0028] figure 2 , image 3 , Figure 4 The exploded views of the structure when the multi-functional box-type detachable swirl distortion generator of the present invention is used to produce three typical distortions of single vortex flow distortion, counter-vortex flow distortion and multi-vortex flow distortion are respectively shown.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com