Locomotive capacitor for protecting casing and column head

A capacitor and shell technology, which is applied in the field of locomotive capacitors, can solve the problems of easily damaged terminal and wire connection, unstable terminal connection, and bulging of the casing, and achieve the effect of protecting the connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

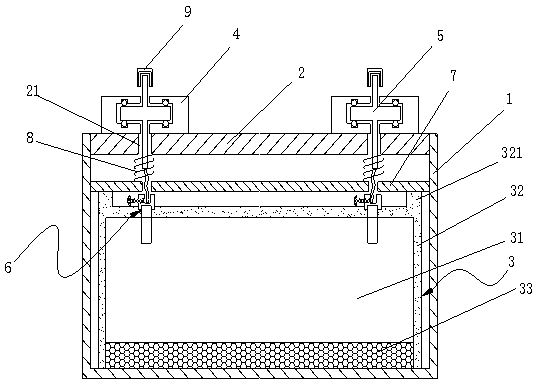

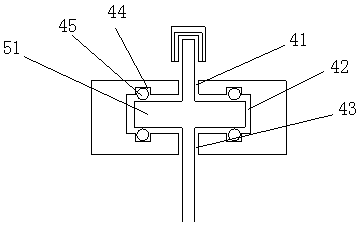

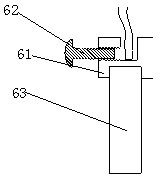

[0026] like figure 1 As shown: a motorcycle capacitor for protecting the housing and the column head, including the housing 1 and the cover plate 2, and the housing 1 and the cover plate 2 are enclosed to form a box body, and a core 3 is installed in the box body; The cover plate 2 is provided with two first round holes 21, and the upper ends of the first round holes 21 are equipped with terminal slots 4, such as figure 2 As shown: the terminal slot 4 is cylindrical, the axial direction of the terminal slot 4 is provided with a first cylindrical hole 41, a second cylindrical hole 42 and a third cylindrical hole 43, the first cylindrical hole 41 and The aperture of the third cylindrical hole 43 is equal, the aperture of the second cylindrical hole 42 is larger than the first cylindrical hole 41, and the upper side wall and the lower side wall of the second cylindrical hole 42 are all provided with an annular groove 44. The annular groove 44 is covered with balls 45, the balls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com