Energy supply system usable under high voltage and energy supply method thereof

A high-voltage, energy-supply technology, applied in circuits, fuel cells, electrical components, etc., can solve problems such as complex design of energy supply systems and energy supply methods, low reliability, difficulty in meeting different energy demands of energy-demanding devices, and achieve Guaranteed continuity and stability, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment provides an energy supply method that can be used under high voltage, including the following steps:

[0060] Obtain high voltage insulating gas;

[0061] Delivering the high-voltage insulating gas to the inside of the fuel cell 2 through the insulating pipeline;

[0062] Electric energy is generated by the fuel cell 2 to supply energy for energy demand devices.

[0063] As an optional implementation, in this embodiment, the fuel cell is a hydrogen fuel cell; the high-voltage insulating gas includes hydrogen and oxygen; the energy-requiring device is a mechanical switch 1 .

[0064] In the above method, there is no need for external electric energy support or supplement, and there is no need for multi-stage voltage transformation. The design is simple and the reliability is high. By controlling the flow rate of high-voltage insulating gas and / or the number of fuel cells, and then controlling the output power, the energy demand can be flexibly met. Acco...

Embodiment 2

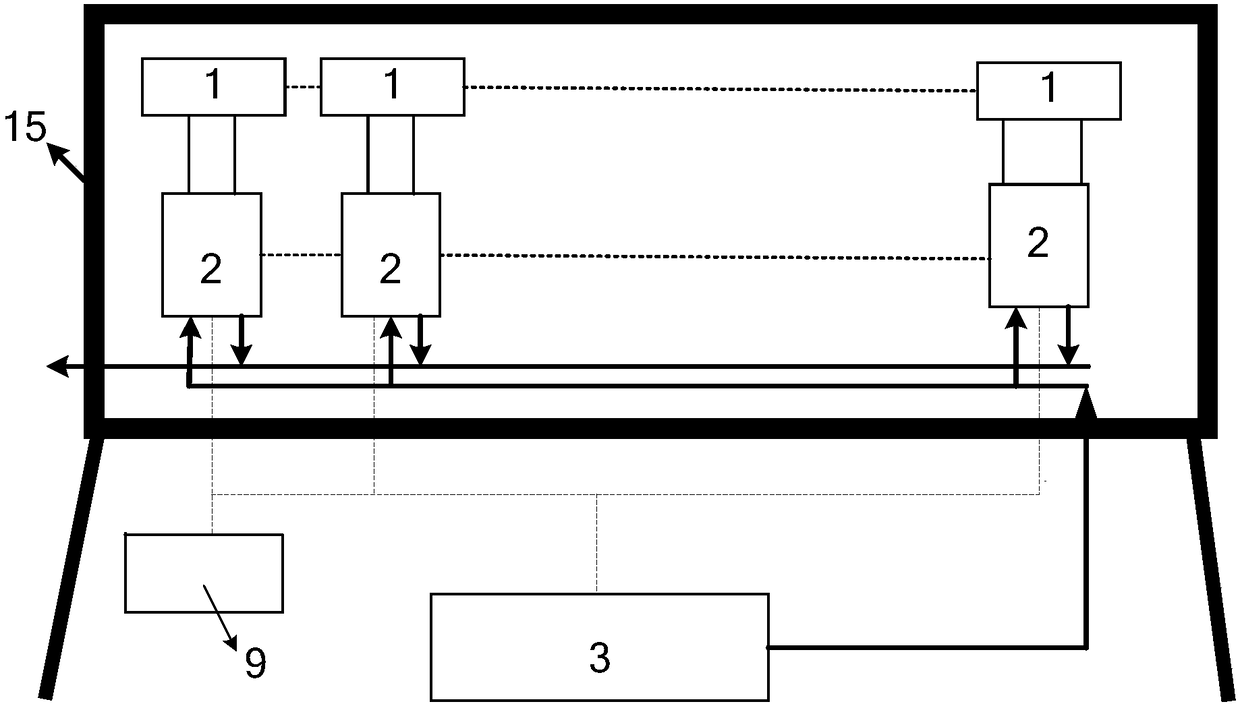

[0080] This embodiment provides an energy supply system that can be used under high voltage, such as figure 1 shown, including

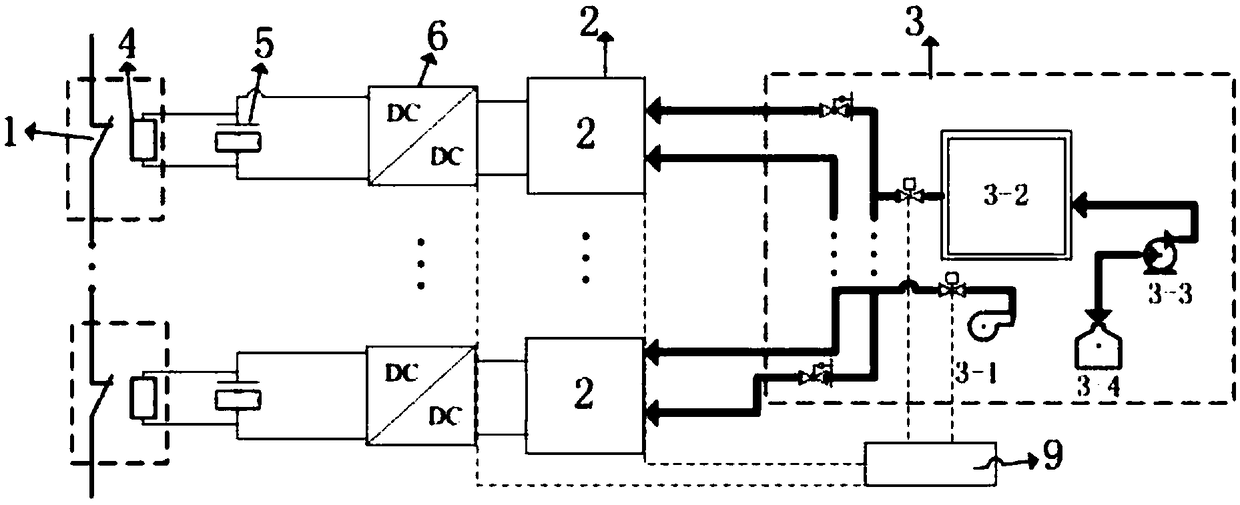

[0081] The gas supply system 3 and the fuel cell 2, the gas supply system 3 and the fuel cell 2 are connected through insulating pipelines to supply gas to the inside of the fuel cell 2;

[0082] The energy demand device is connected with the fuel cell 2 to supply the energy demand device with the electric energy generated by the fuel cell 2 .

[0083] As an optional implementation, in this embodiment, the fuel cell is a hydrogen fuel cell; the energy demand device is a mechanical switch 1 , more preferably an electromagnetic relay.

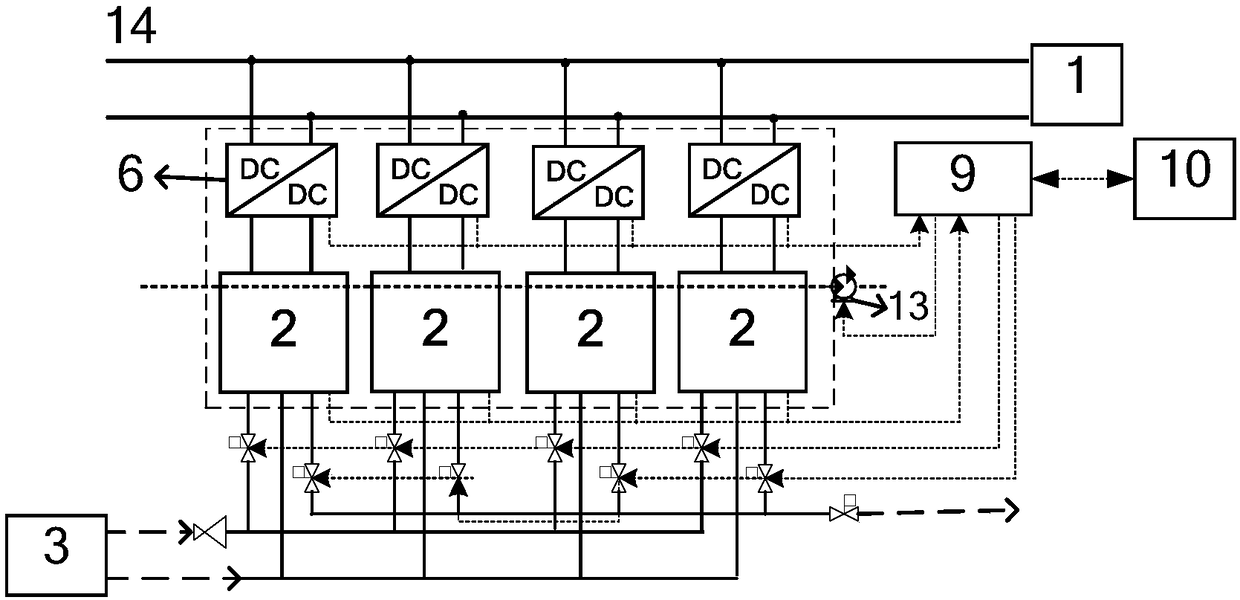

[0084] As an optional implementation, according to actual needs, the number of fuel cells 2 is n, and n is a positive integer. In this embodiment, as figure 2 As shown, the number of fuel cells 2 is one; in another embodiment, the number of fuel cells 2 is at least four, which are arranged in parallel with each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com