Parallel clamping manipulator device

A technology of manipulators and splints, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of inflexibility, large space occupation, and high requirements for component matching accuracy, and achieve the effect of firm arrangement and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

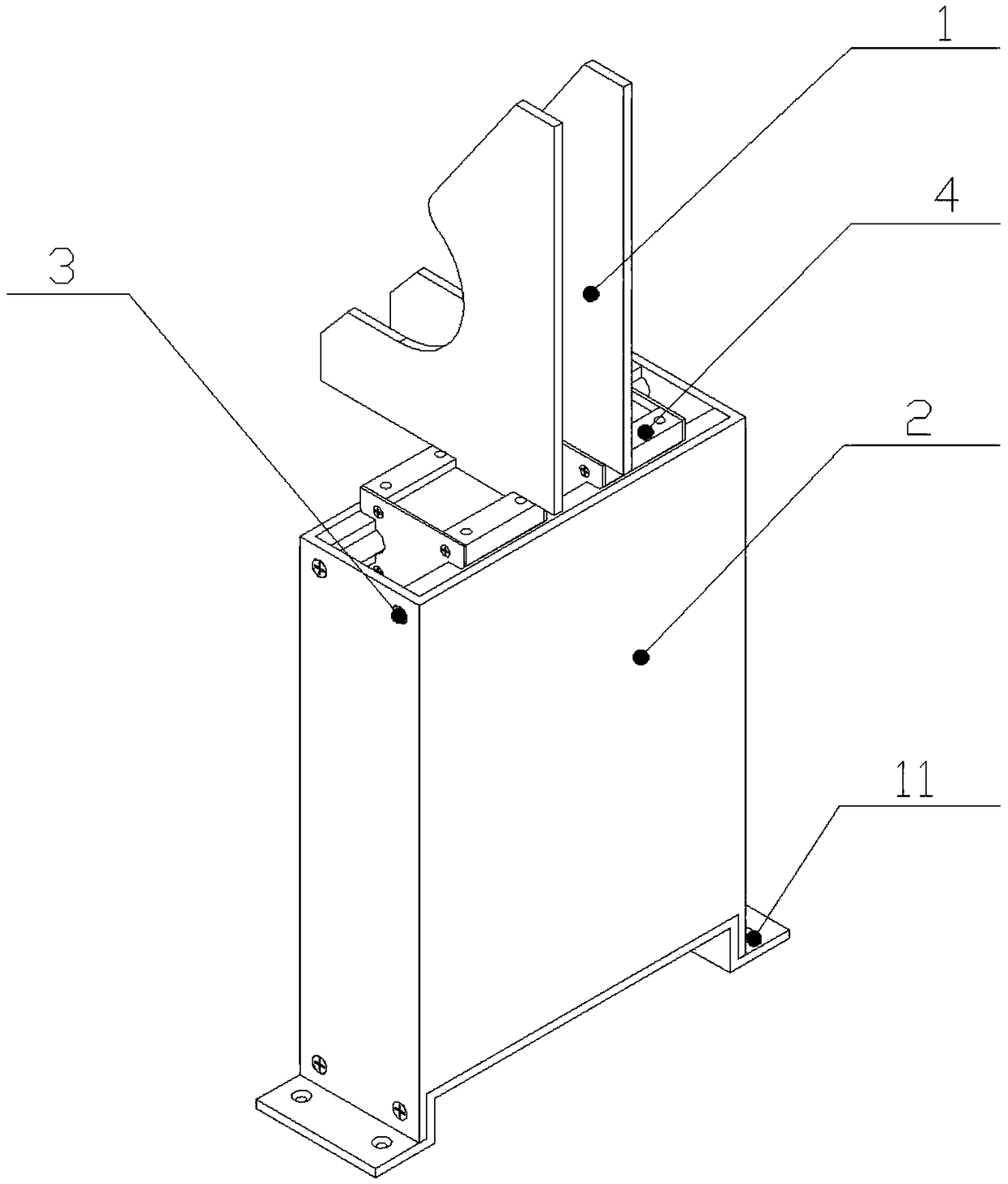

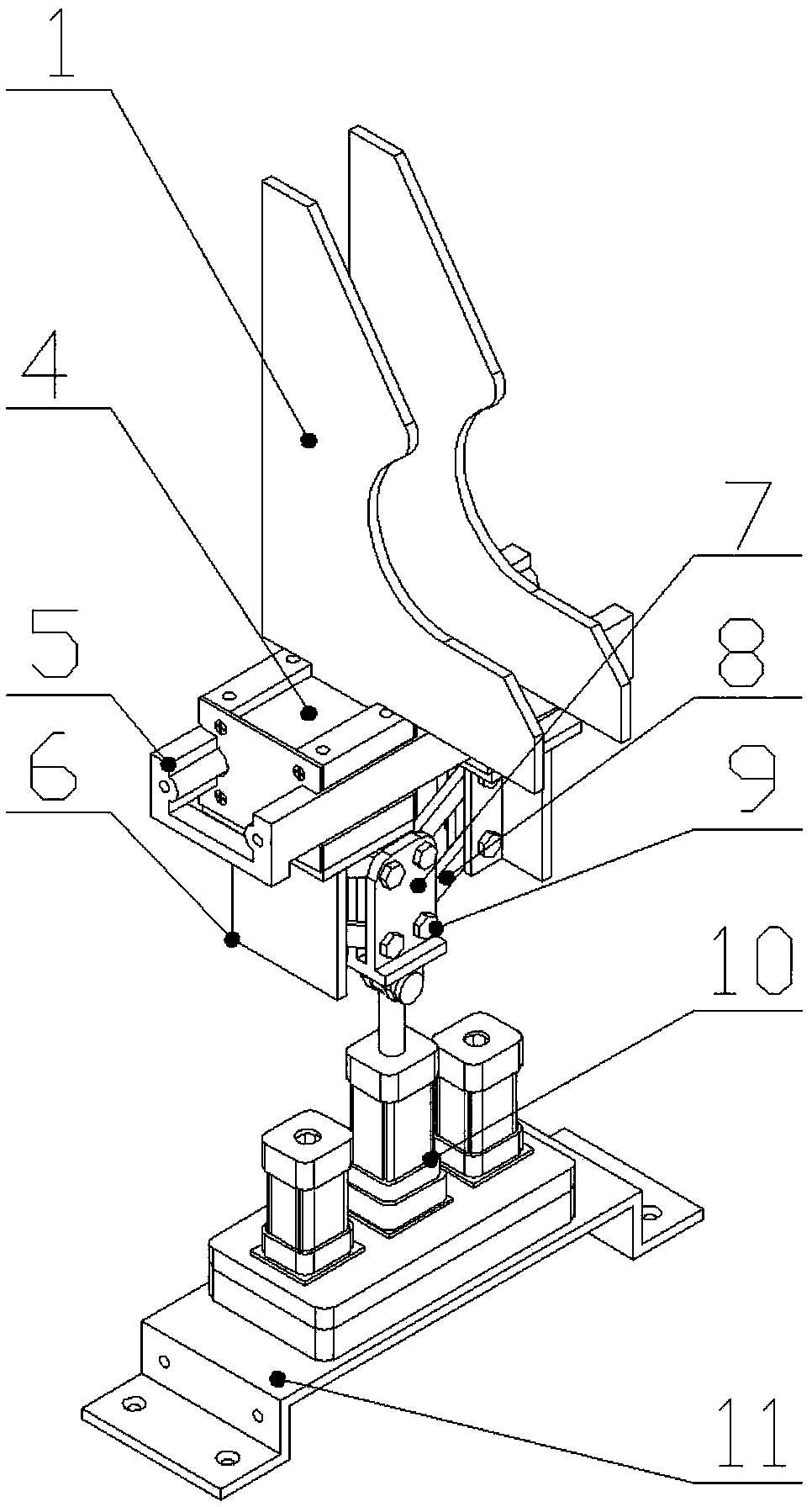

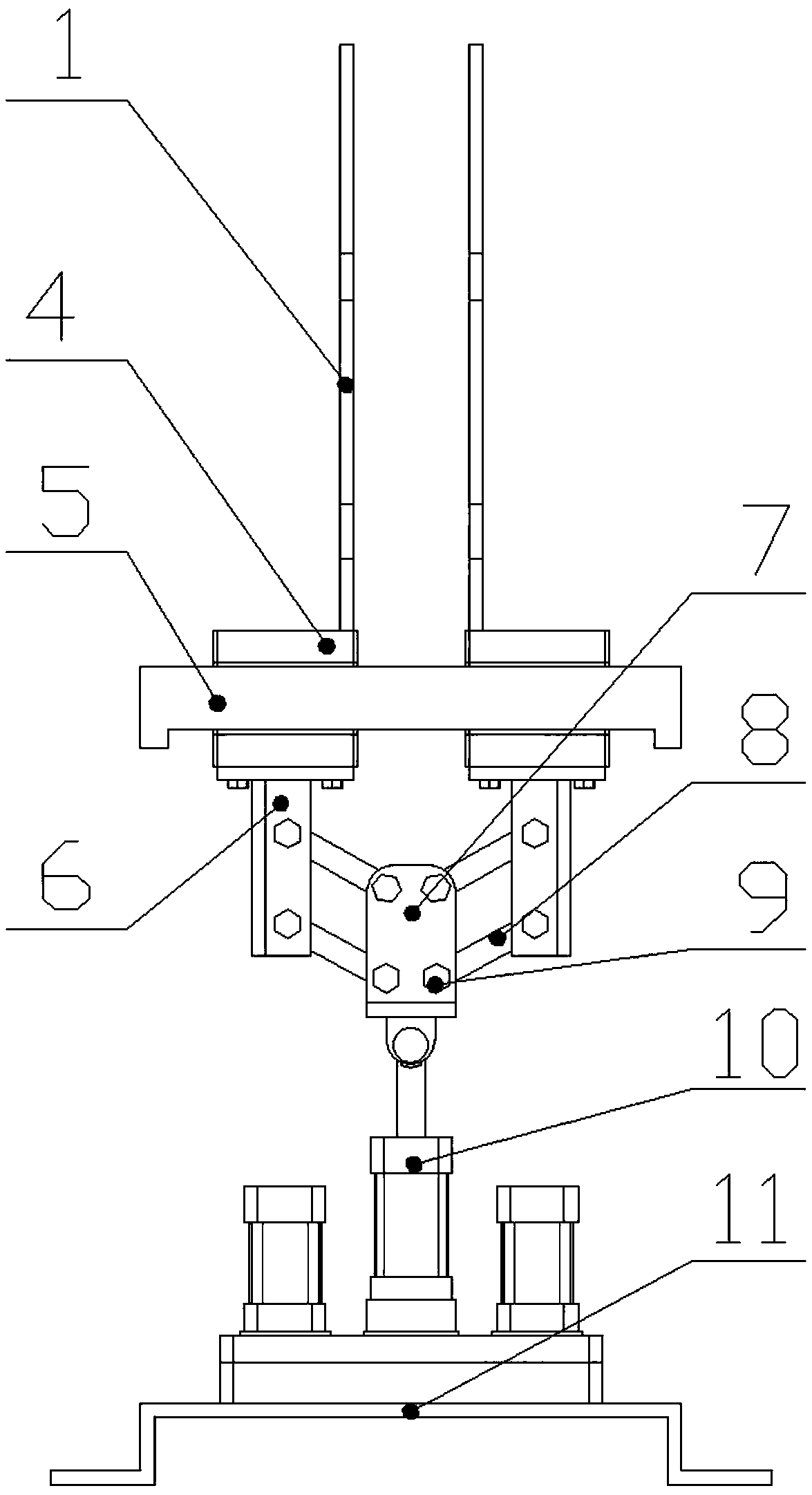

[0026] A robotic device for parallel gripping, such as figure 2 , 3 As shown, it consists of a fixed seat (11), an electric cylinder (10), a hinged four-bar mechanism, a slider (4), a slideway body (5), and a splint (1), wherein the fixed seat (11) is Convex shape design, with fixing screw connection holes on it, and fixed connection with the mechanical arm through the connection screw (3); Figure 9 As shown, the electric cylinder (10) is composed of a servo motor (101), a screw (102), a casing (103), and a cylinder (104), and the casing (103) is connected to the fixing seat ( 11) The convex panel is fixedly connected, the servo motor (101) and the cylinder (104) are fixedly installed on the box body (3), the cylinder (104) is in the middle, and the servo motors are on both sides of the cylinder (104) (101), the screw mandrel (102) is fixedly mounted on the cylinder barrel (104); the hinged four-bar mechanism is a parallelogram mechanism, such as Figure 4 As shown, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com