Polymer foaming and forming device

A foam molding and polymer technology, applied in the field of polymer foam molding equipment, can solve the problems of high heating temperature, long heating time, heating dead angle, etc., and achieve the effects of improving production efficiency, fast heating speed and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

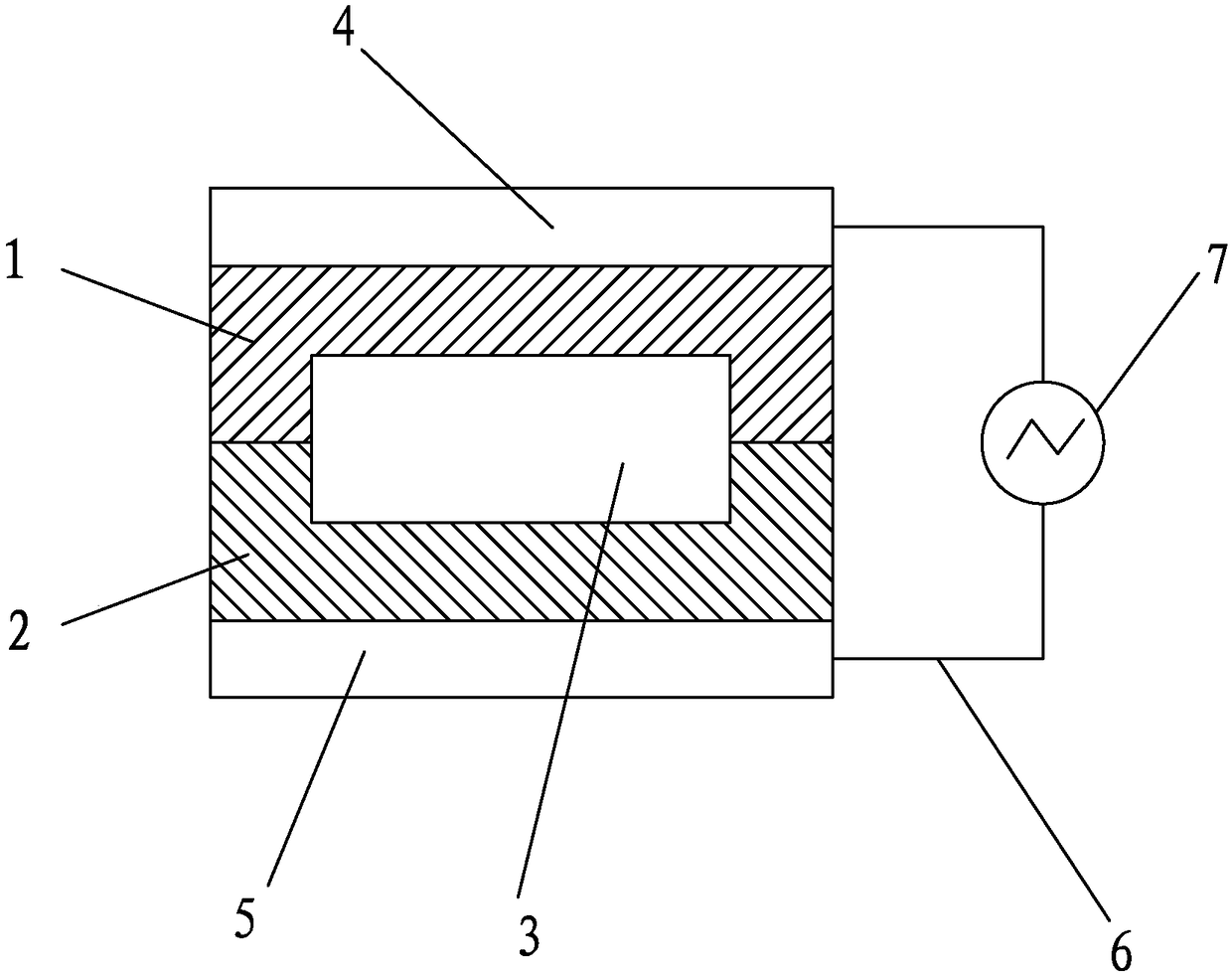

[0021] like figure 1 As shown, the polymer foam molding device of the present invention includes a mold, a radio frequency electrode A4, a radio frequency electrode B5 and a radio frequency power supply 7. The upper mold 1 and the lower mold 2 are molded to form a closed mold cavity 3, and the radio frequency electrode A4 and the radio frequency electrode B5 are respectively arranged on the outer surface of the upper mold 1 and the outer surface of the lower mold 2, so The radio frequency electrode A4 and the radio frequency electrode B5 are respectively connected to the positive pole and the negative pole of the radio frequency power supply 7 via the cable 6 . In the present invention, an indoor power supply or an industrial power supply is used as the radio frequency power supply 7 to supply power to the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com