Yarn selection control structure

A technology for controlling structure and yarn selection, which is applied in textiles and papermaking, weft knitting, knitting, etc. It can solve the problems of high production cost, difficulty in production and assembly, and economical reduction, so as to improve product economy and practicability, The effect of simplifying the internal structure and production process, reducing weight and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

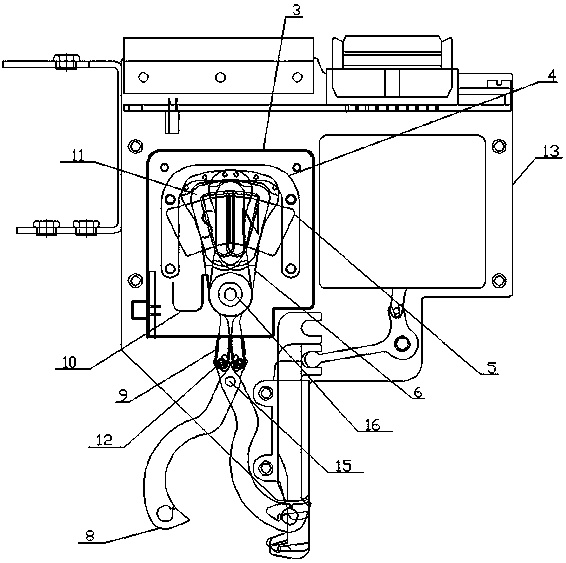

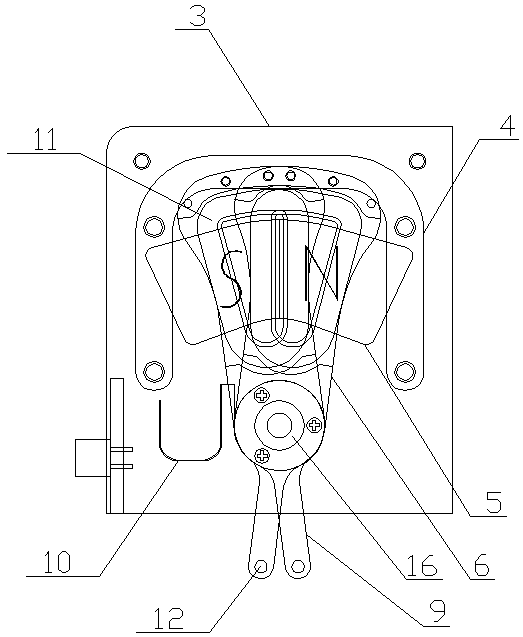

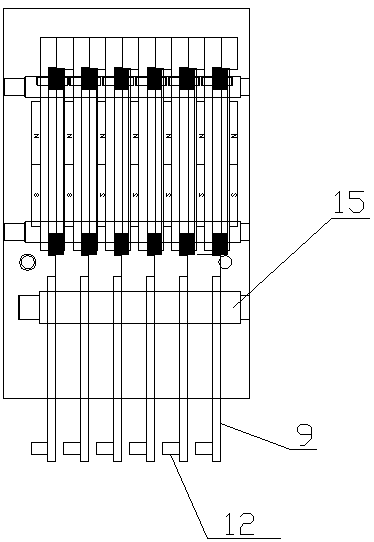

[0039] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , a yarn selection control structure, including a controller housing 3 and a yarn feeding finger 8 arranged on the outer plate 13 of the yarn changer, a swing arm 6 is installed in the controller housing 3 through a rotating shaft 15, and the two sides of the swing arm 6 A permanent magnet 5 is arranged in parallel, and a coil 11 is arranged on the swing arm 6. The coil 11 and the permanent magnet 5 are placed in parallel to form a voice coil motor. The force of the wire, this thrust pushes the coil 11 to swing around its rotating shaft 15, that is, when the voice coil motor is energized and the direction of energization changes, the swing arm 6 can swing around the rotating shaft 15, and the swing arm 6 is driven by the voice coil motor. Yarn finger 8 swings to complete the...

Embodiment 2

[0049] see Figure 16 , Figure 17 , Figure 18 , the difference from Embodiment 1 is that: the yarn feeding finger 8 is installed on the controller housing 3 through the rotating shaft 15, and the swing arm 6 is provided with a wear-resistant block 2, which increases the stability and wear resistance of the swing arm 6, and the controller The housing 3 is provided with a partition plate 7 for isolating the yarn selection components and the yarns.

Embodiment 3

[0051] The difference from Embodiment 1 is that the swing arm 6 and the yarn feeding finger 8 are integrally formed.

[0052]The invention simplifies the internal structure and production process, adopts a new voice coil motor, is easy to manufacture and assemble, and improves product economy and practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com