Non-integrated steel ball type lock wall steel plate warping prevention device

A non-integrated, anti-warping technology, used in ship lifting devices, ship locks, climate change adaptation, etc., can solve the problems of tearing and falling off, cracking, and inability to protect the lock wall, etc. The effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

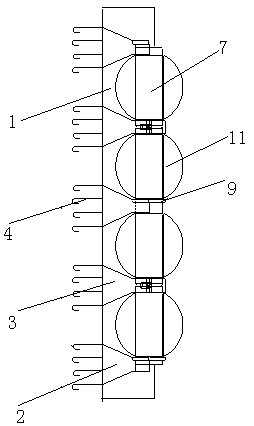

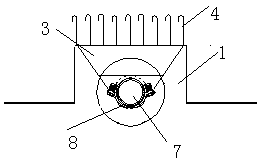

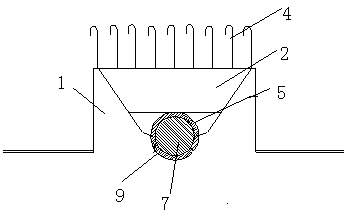

[0028] like Figure 1~5 As shown, a non-integrated steel ball type lock wall anti-warping device disclosed by the present invention is mainly installed in the lock head, lock wall or approach channel of the ship lock, and is located at the joint between the steel plate and the steel plate. The specific structure is in The installation position is first provided with a strip-shaped groove 1 to facilitate the installation of the device. The strip-shaped groove is usually 250mm wide and 129mm deep. At the position of the water level, when the steel plate on the gate wall is mounted, the mounting extends to the opening of the groove.

[0029] Multiple pressure-bearing supports 2 and hoop supports 3 are longitudinally anchored in the elongated groove, the pressure-bearing supports and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com