Round-gallery multi-bin type underground comprehensive pipe gallery

A technology of integrated pipe gallery and pipe gallery, which is applied to underwater structures, water conservancy projects, artificial islands, etc., can solve the problems of poor top-bearing anti-settling performance, poor anti-leakage performance of pipe gallery interfaces, and high construction costs. Achieve the effects of excellent anti-leakage performance of pipe joints, reliable pipeline stability and shortened construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

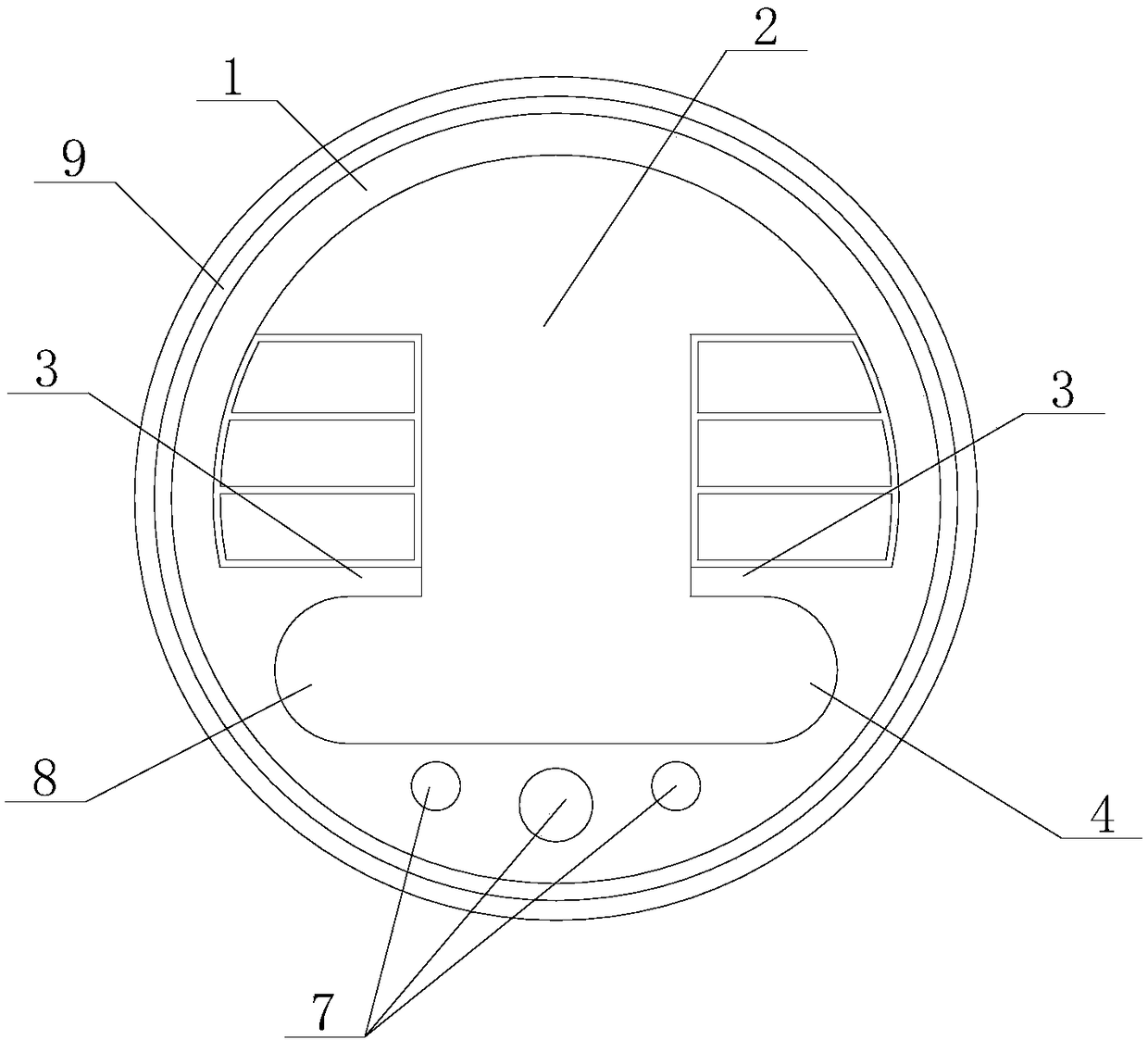

[0021] refer to figure 1 , the underground comprehensive pipe gallery described in this embodiment includes a pipe gallery main body 1, the cross section of the pipe gallery main body 1 is circular, and an outwardly protruding ring-shaped pipe gallery joint 9 is provided on the end surface of one end thereof. The end surface of one end is provided with an inwardly concave annular pipe gallery joint slot; the upper space 2 of the inner cavity of the pipe gallery main body 1 is the intelligent and ventilation space of the pipe gallery; the left side of the pipe gallery main body 1, The middle part of the inner wall on the right side is provided with a cable placement platform 3 respectively, and the cable placement platform 3 also has a lifting function for installing and maintaining pipelines; Side compartment 4; the lower part of the pipe gallery main body 1 is provided with several independent pipeline installation cabins 7.

Embodiment 2

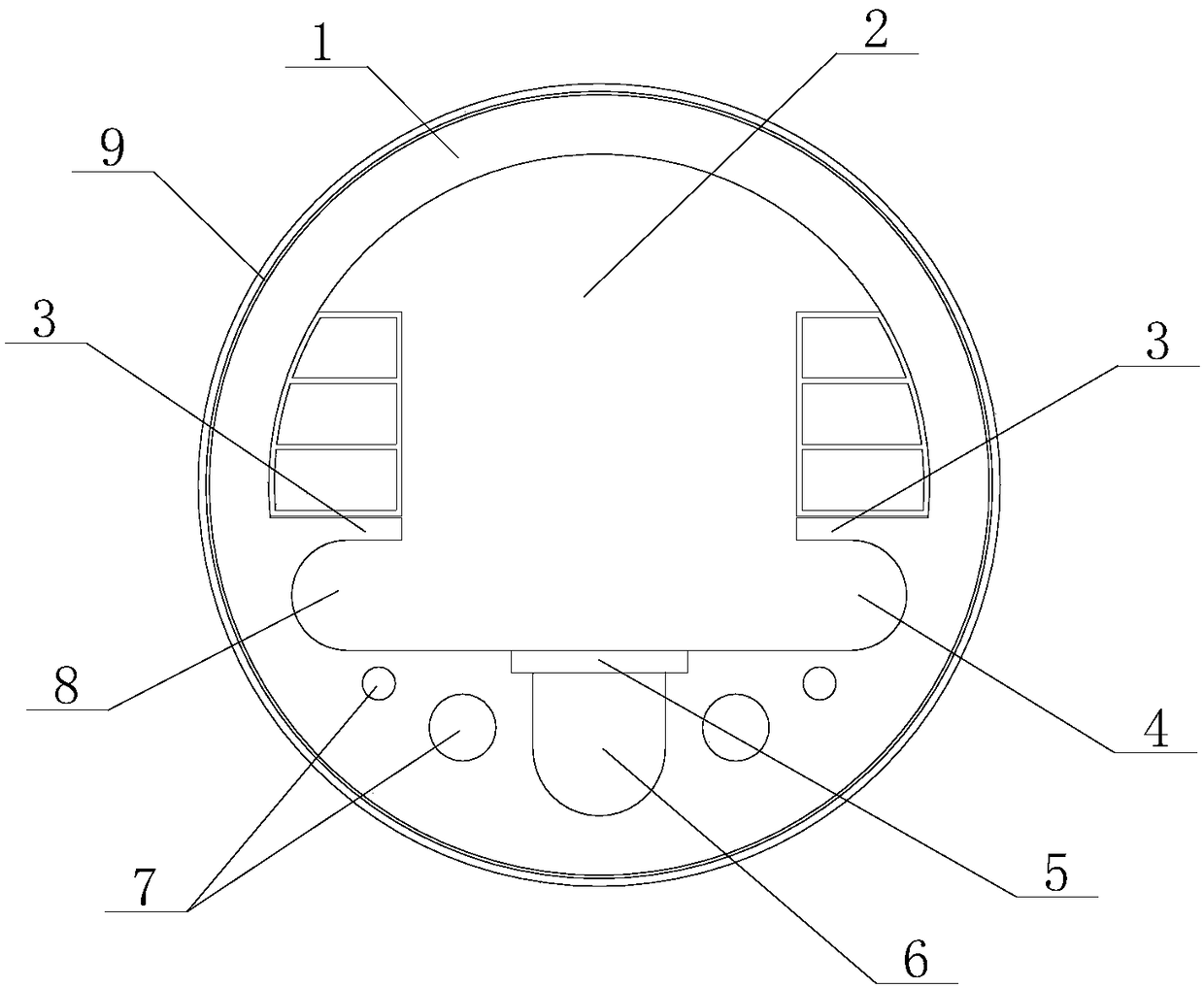

[0023] refer to figure 2 , the underground comprehensive pipe gallery described in this embodiment includes a pipe gallery main body 1, the cross section of the pipe gallery main body 1 is circular, and an outwardly protruding ring-shaped pipe gallery joint 9 is provided on the end surface of one end thereof. The end surface of one end is provided with an inwardly concave annular pipe gallery joint slot; the upper space 2 of the inner cavity of the pipe gallery main body 1 is the intelligent and ventilation space of the pipe gallery; the left side of the pipe gallery main body 1, The middle part of the inner wall on the right side is provided with a cable placement platform 3 respectively, and the cable placement platform 3 also has a lifting function for installing and maintaining pipelines; Side compartment 4; the lower part of the pipe gallery main body 1 is provided with a lower part compartment 6, and the top opening of the lower part compartment 6 is provided with an is...

Embodiment 3

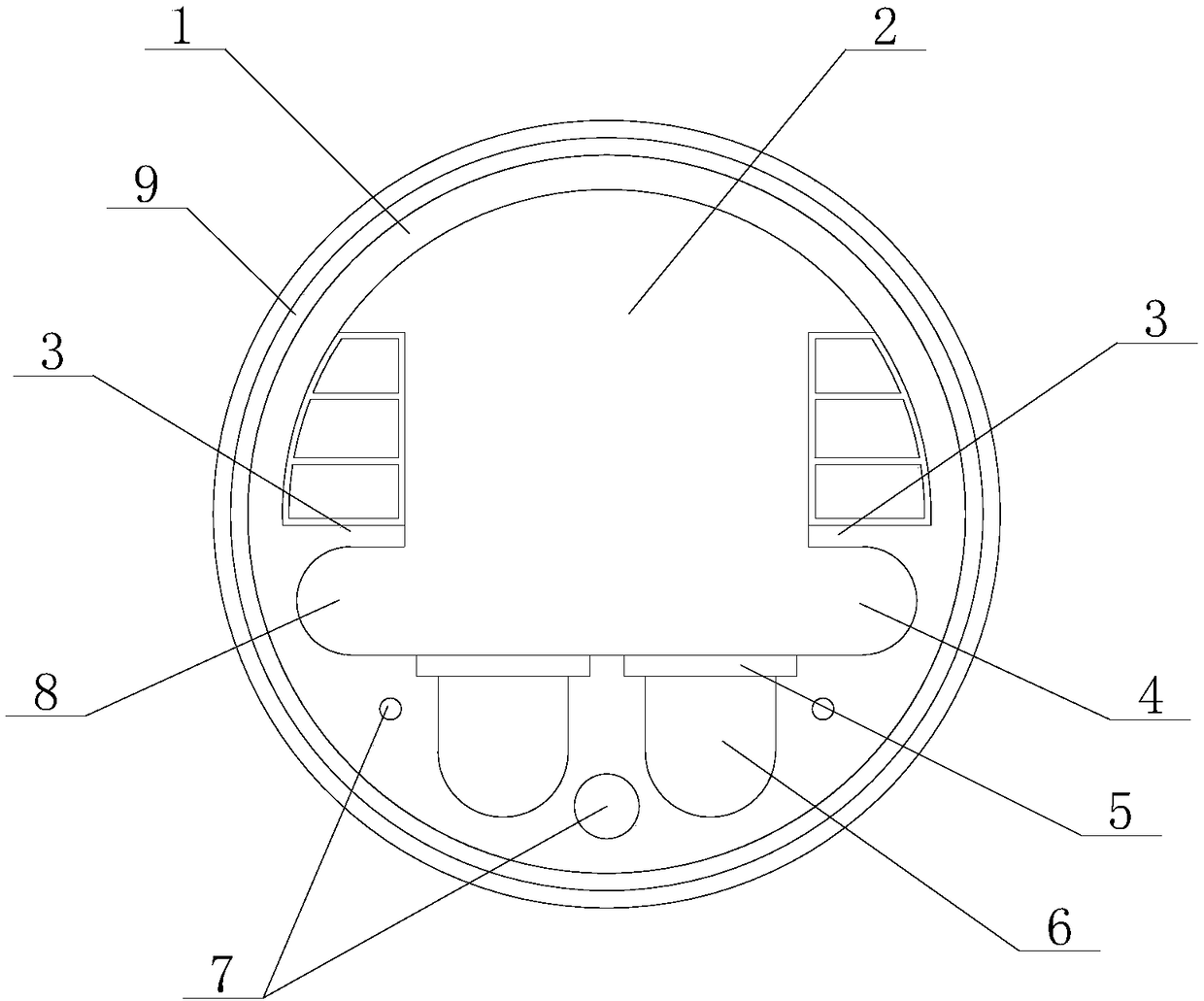

[0025] refer to image 3 , the underground comprehensive pipe gallery described in this embodiment includes a pipe gallery main body 1, the cross section of the pipe gallery main body 1 is circular, and an outwardly protruding ring-shaped pipe gallery joint 9 is provided on the end surface of one end thereof. The end surface of one end is provided with an inwardly concave annular pipe gallery joint slot; the upper space 2 of the inner cavity of the pipe gallery main body 1 is the intelligent and ventilation space of the pipe gallery; the left side of the pipe gallery main body 1, The middle part of the inner wall on the right side is provided with a cable placement platform 3 respectively, and the cable placement platform 3 also has a lifting function for installing and maintaining pipelines; Side compartments 4; the lower part of the pipe gallery main body 1 is provided with two lower compartments 6, and the top openings of the two lower compartments 6 are provided with isola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com