Setting ball seat with secondary opening function

A technology of setting ball seat and re-opening, applied in sealing/isolation, wellbore/well valve device, wellbore/well components, etc., can solve economic loss, scrapping of whole well, affecting single well production, etc. problems, to achieve the effect of reducing the number of fracturing stages and reducing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

[0020] Taking a compression packer staged fracturing string applied to an open-hole horizontal well with a Φ152.4mm drill bit as an example, the present invention will be further described in detail.

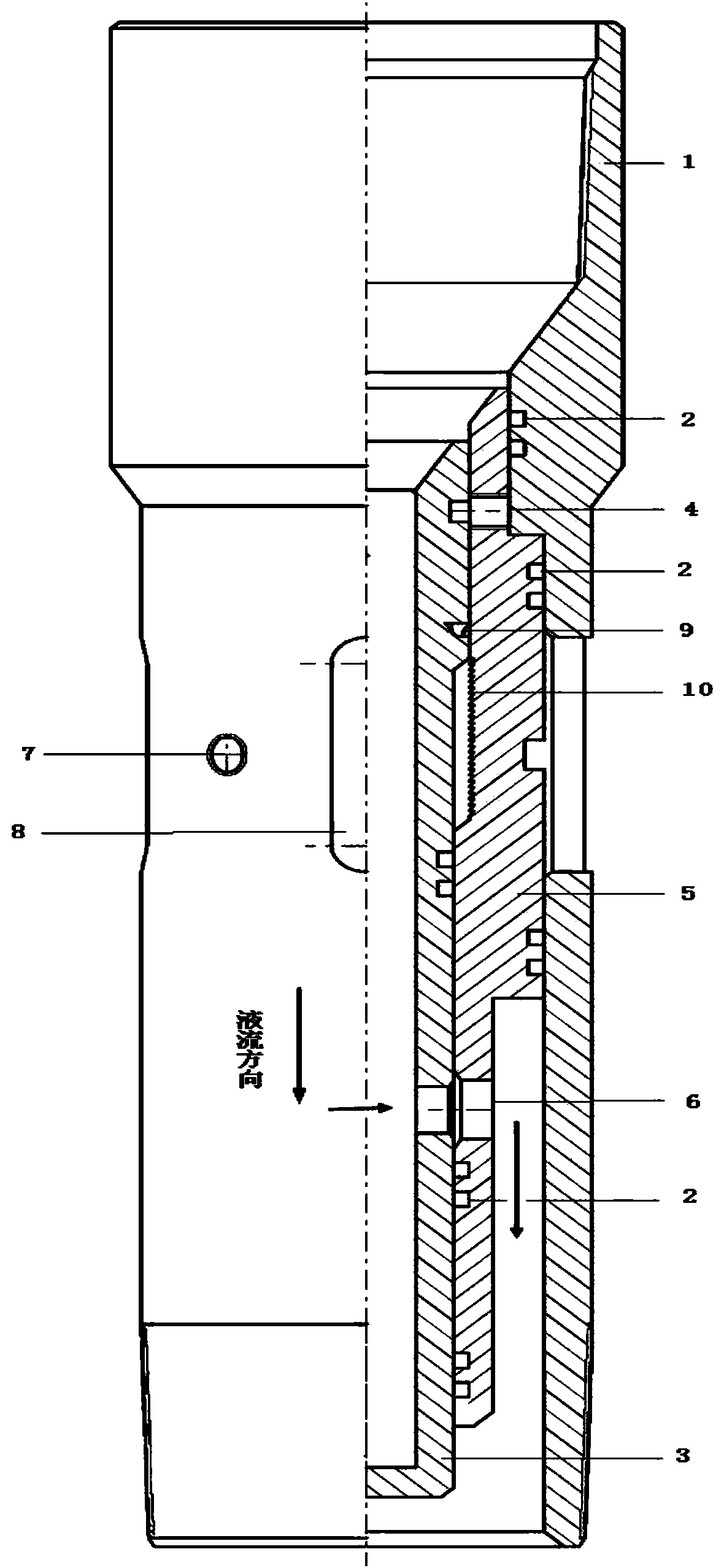

[0021] see figure 1 , the setting ball seat with secondary opening function of the present invention is composed of body 1, sealing ring 2, setting sliding sleeve 3, setting sliding sleeve scissors 4, communicating sliding sleeve 5, circulation port 6, communicating sliding sleeve scissors 7. Composed of a fracturing port 8, a locking ring 9 and a locking buckle 10. The upper and lower ends of the body 1 have internal and external threads respectively, and there is a fracturing port 8 in the middle; the connecting sliding sleeve 5 is connected to the main body 1 through the connecting sliding sleeve shear pin 7, and the connecting sliding sleeve 5 restricts its upward m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap