Nondestructive detecting method for surface defects of plate structures

A technology of non-destructive testing and plate structure, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problems that surface wave sensors cannot meet the detection requirements, and achieve large Range detection capability, high detection sensitivity, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

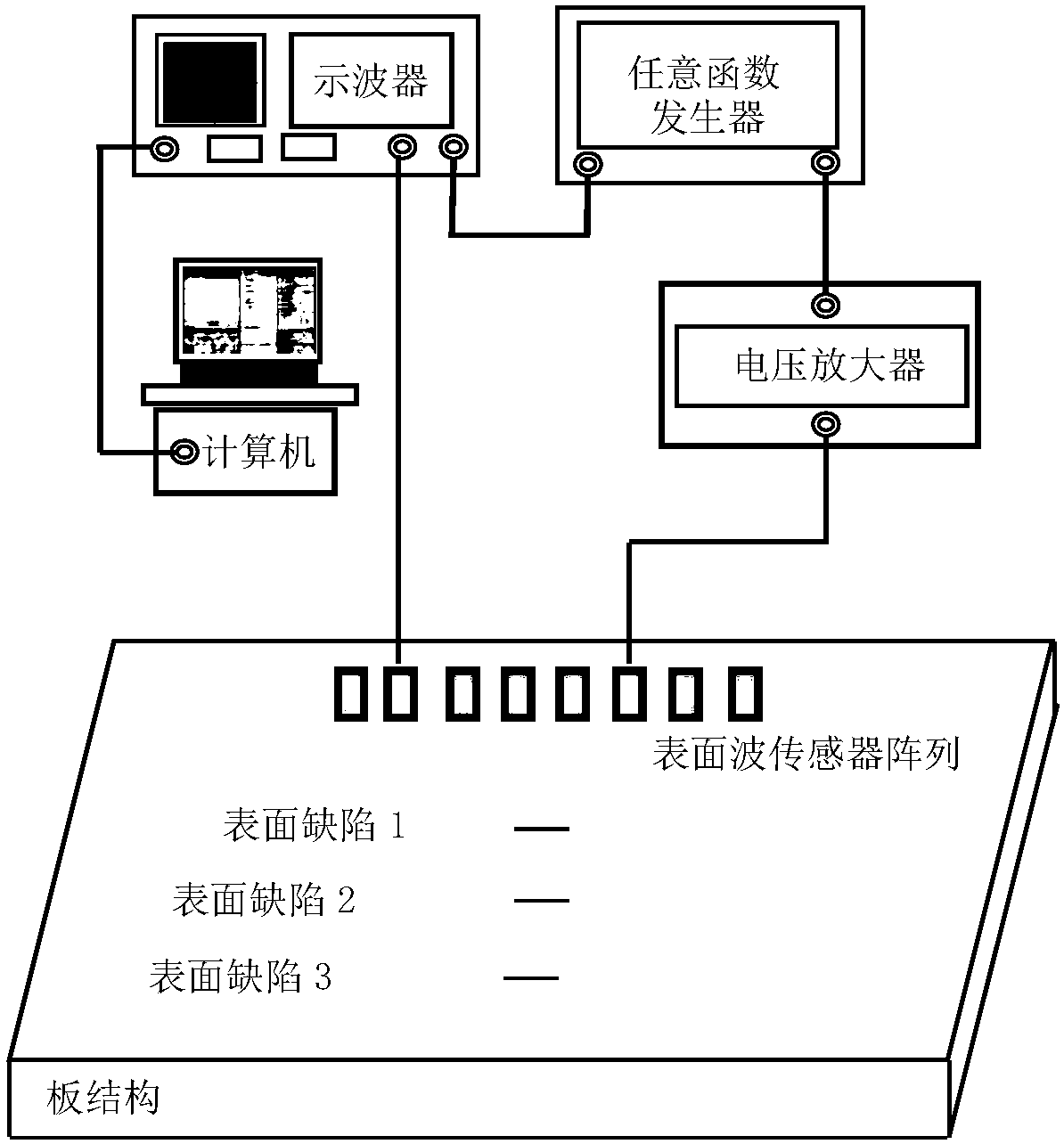

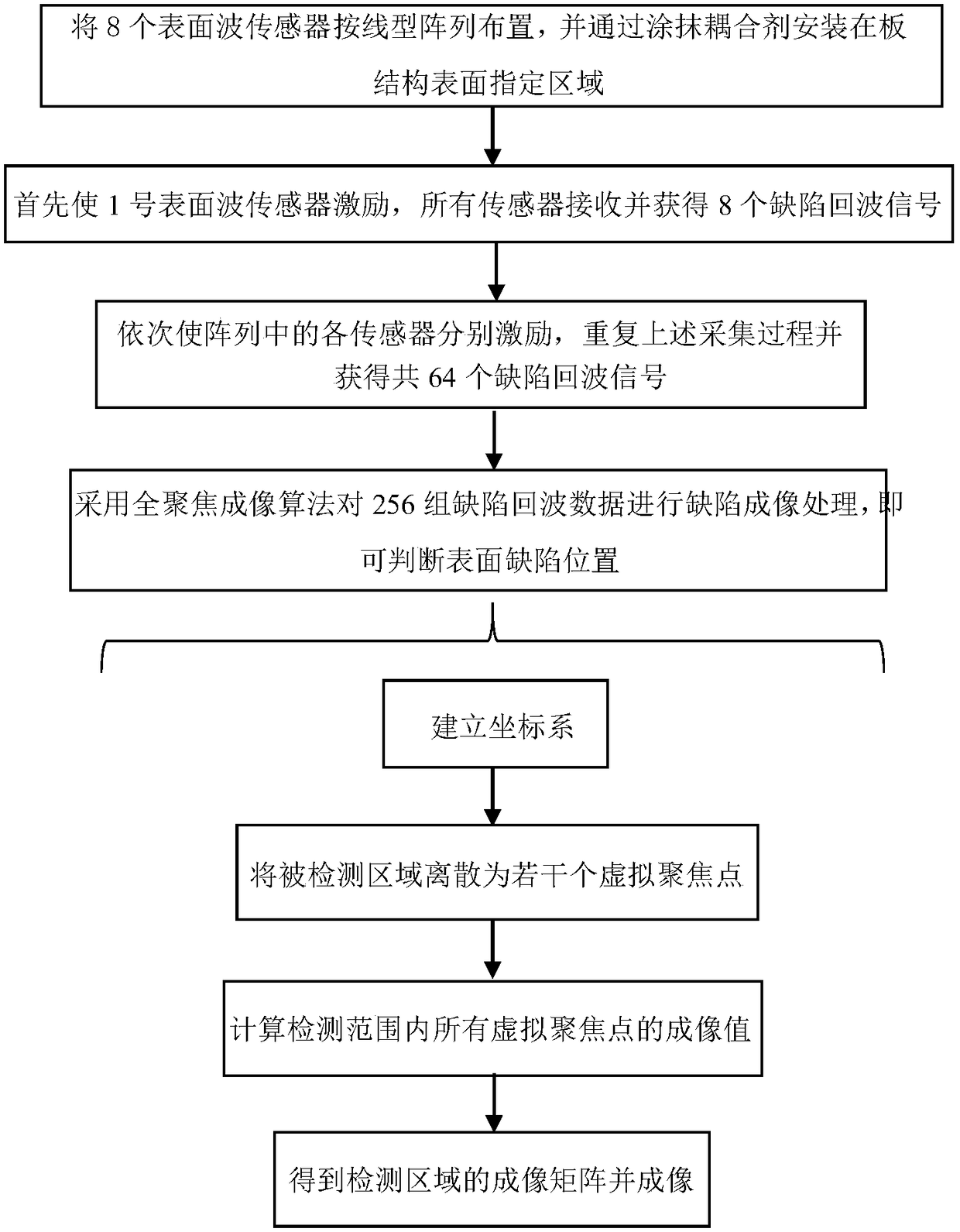

Embodiment 1

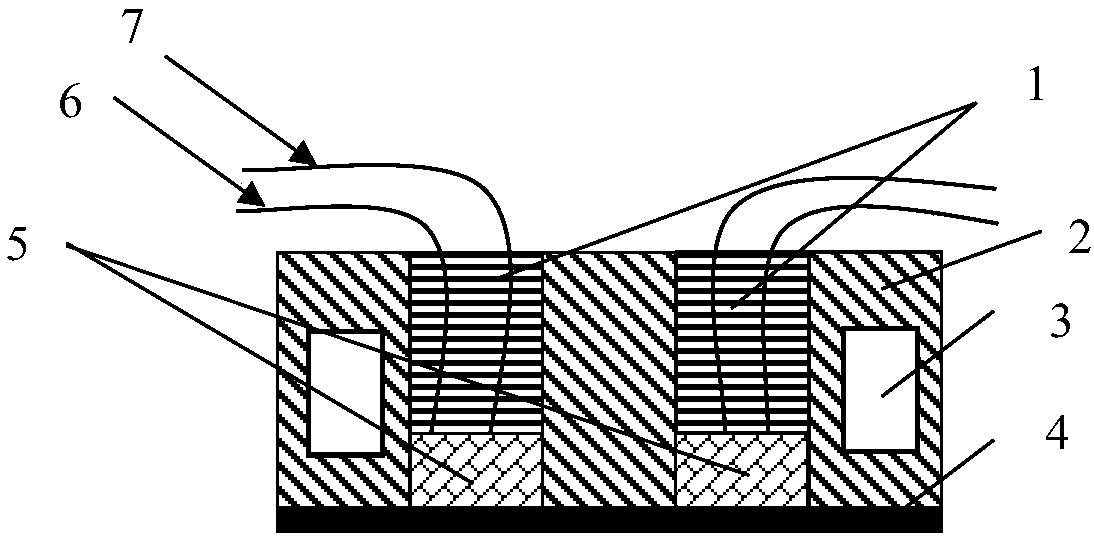

[0041] The center frequency of the surface wave sensor used is 0.5MHz, and the piezoelectric ceramics in the thickness vibration mode is used as the sensitive element. The element width is 3mm, the element center distance is 6mm, the element length is 20mm, and the element thickness is 1mm. The experimental setup and the location of the all-focus imaging area are as follows: Figure 6 As shown, the sensors are equally spaced along the x-axis with a pitch of 20mm. The three defects are all surface crack defects, the lengths are 1.5mm, 2.5mm and 3mm, the width is 1mm, and the depth is 5mm. All-focus imaging was performed on a 50 mm × 100 mm area containing 3 defects.

[0042] Figure 2-Figure 7 The non-destructive testing process and test results of the surface defects of the plate structure in this embodiment are given. It can be seen that this method can accurately detect the surface defects of the plate structure, and solve the problem that a single surface wave sensor cann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com