Magnetic pole spaced arrangement combined stator

A permutation and combination technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, winding, etc., can solve problems such as large cogging torque, small cogging torque, and small additional torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention is further described below in conjunction with accompanying drawing.

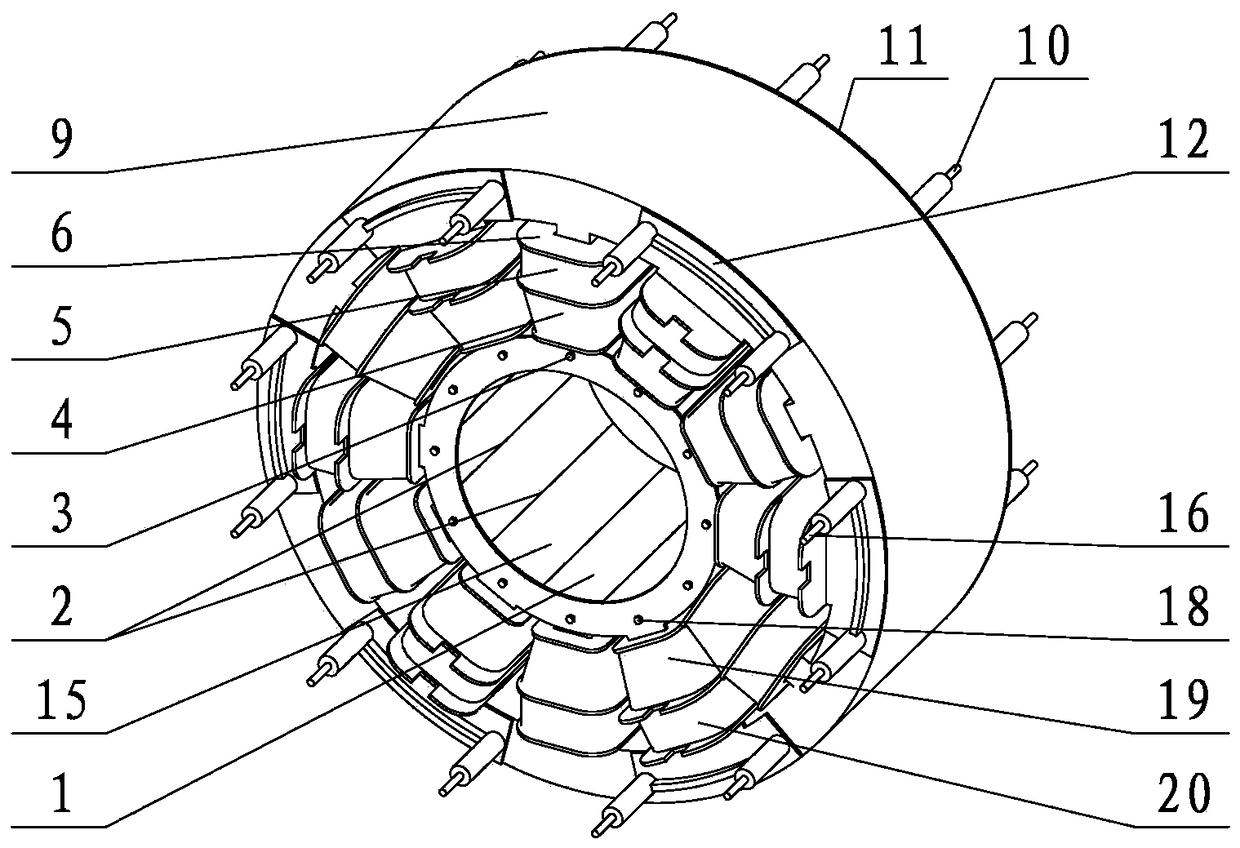

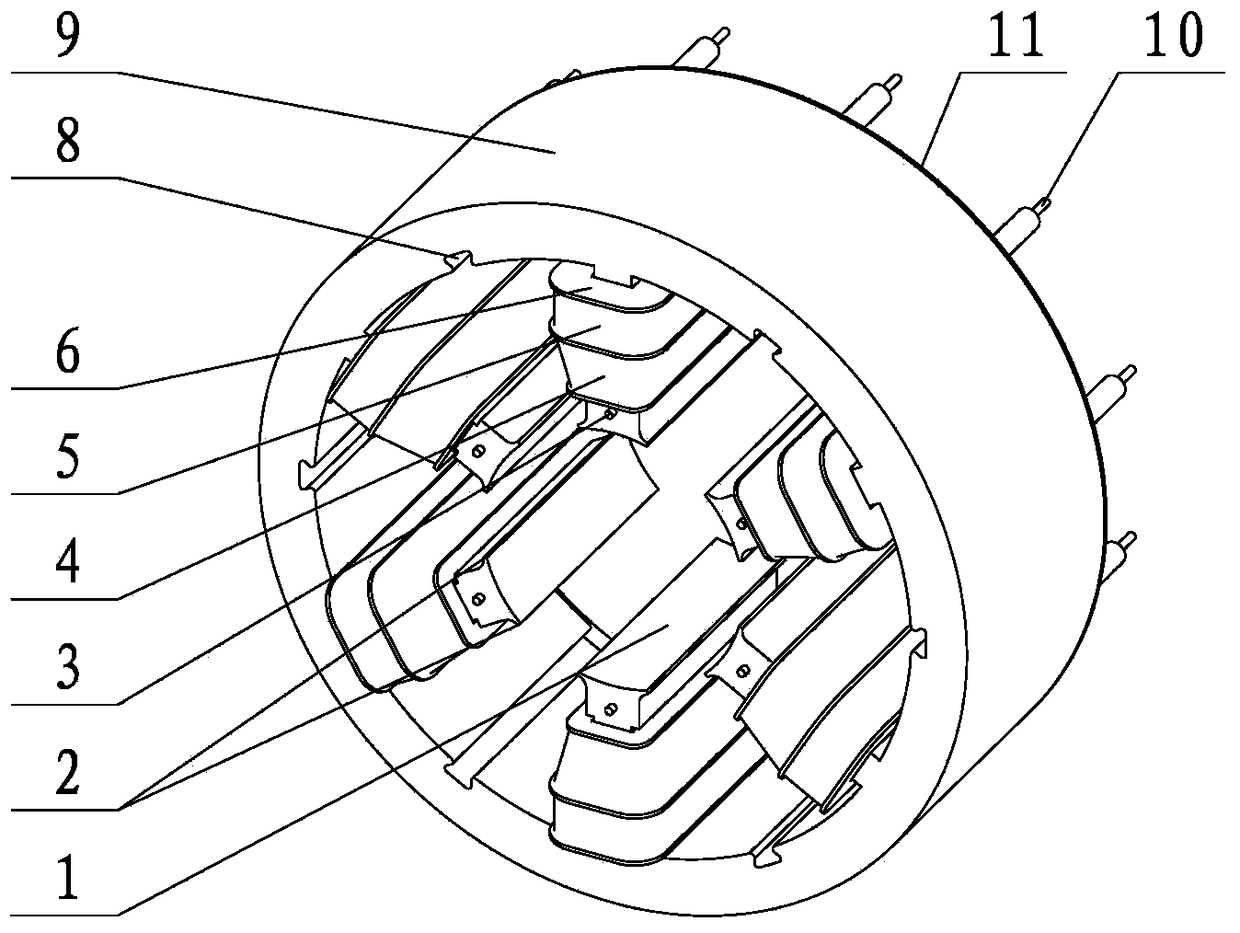

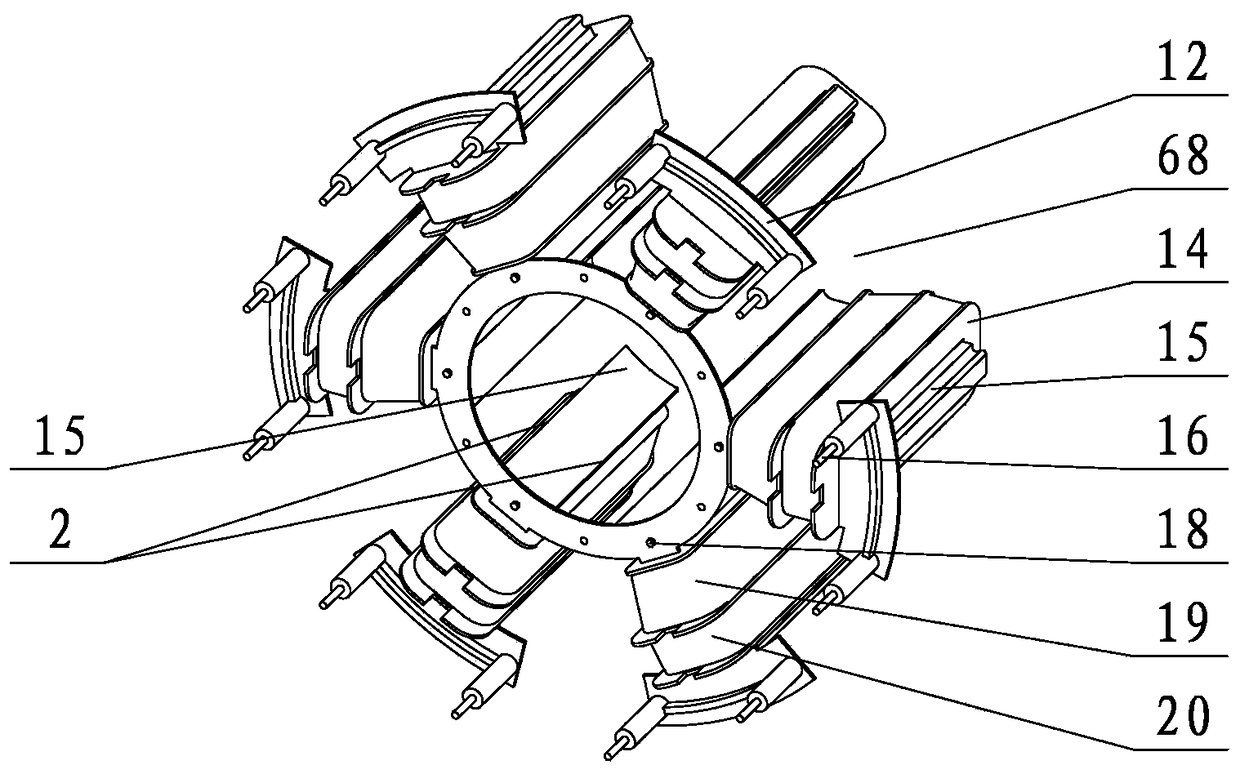

[0055] refer to figure 1 , figure 2 , image 3 , the combined stator includes a stator component and a stator insert component. The stator component includes a stator core 9 , a positioning pin 3 , a welding pin 10 , an annular coil bobbin 11 , and a coil bobbin 1 6. The annular bobbin 11 includes several positioning bobbins 27, and each positioning bobbin 27 and bobbin 6 respectively have one or several bobbin slots, if each positioning bobbin 27 and bobbin 6 If there is a skeleton wire groove respectively, then the stator part also includes a coil one, if each positioning coil skeleton one 27 and the coil skeleton one 6 have two skeleton wire grooves respectively, then the stator part also includes an inner coil one 4 and an outer coil one 5 . The stator insert part includes an annular coil bobbin two 12, a coil bobbin two 14, a magnetic pole insert 15, a welding pin two 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com