A solid rocket motor charge grain structure

A technology of solid rockets and motors, applied in rocket motor devices, machines/engines, mechanical equipment, etc., can solve problems such as uneven distribution of stress and strain, increase slot size, reduce filling fraction, etc., to achieve increased volumetric energy density, The effect of reducing the slot width and increasing the filling ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

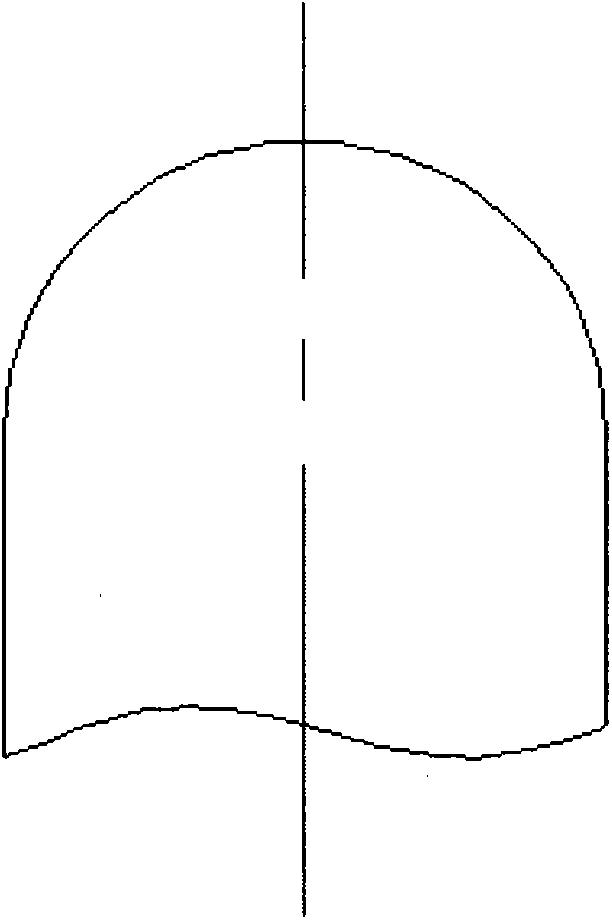

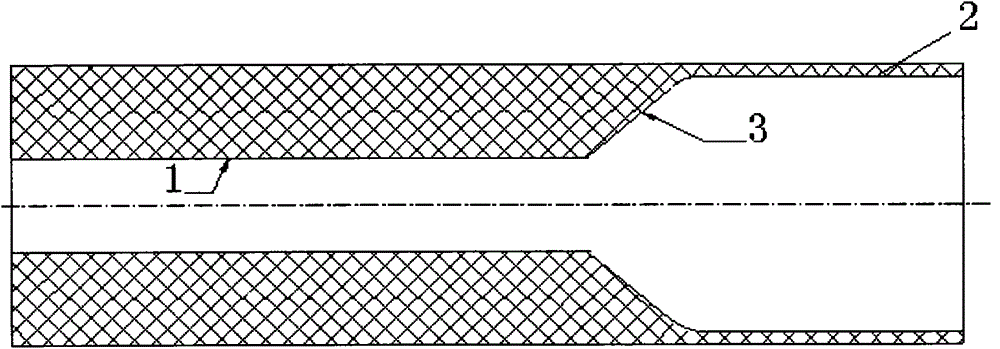

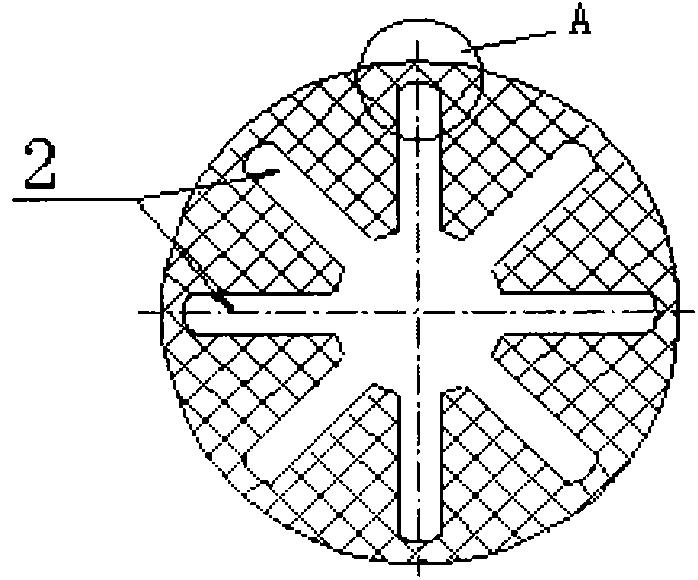

[0019] Such as figure 2 As shown, the present invention provides a solid rocket motor charge grain structure, including the charge grain inner tube 1 and the slot 2 connected to each other, and the charge grain inner tube 1 and the slot 2 pass through the transition chute 3 connection, such as image 3 , Figure 4 As shown, the longitudinal section of the groove bottom of the slot 2 is an axisymmetric structure, and the left half of the axisymmetric structure includes sequentially connected: a first arc with a radius of R1 and a second arc with a radius of R2 , and a straight line with a length of L / 2, wherein, R1 is not equal to R2, and the first arc is tangent to the second arc, L is 0.1K-0.15K, R1 is 0.15K-0.2K, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com