Tyre

A tire and tire circumferential technology, applied in the direction of heavy tires, tire parts, tire tread/tread pattern, etc., can solve problems such as pattern block cracks, and achieve the effect of improving rolling resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

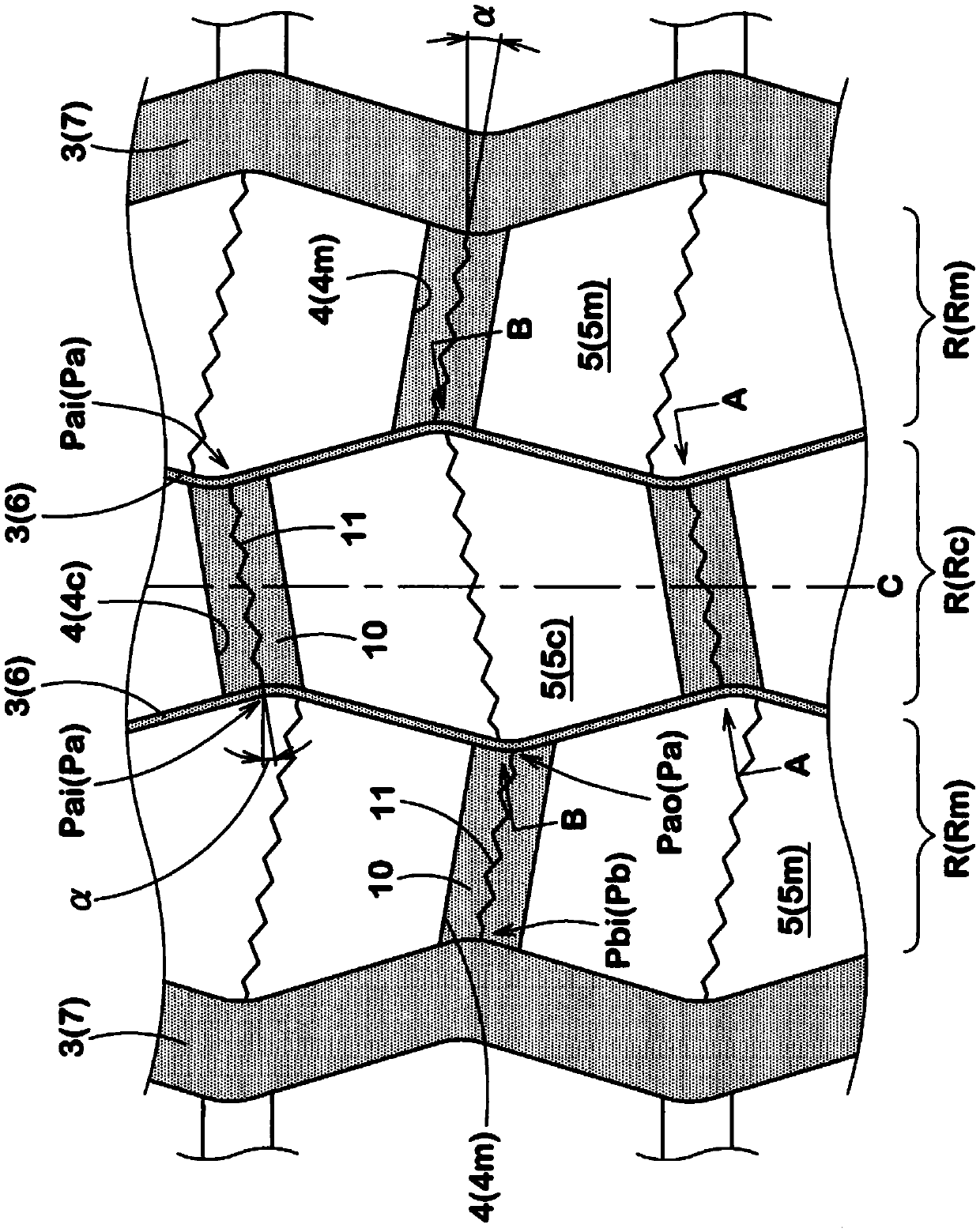

[0044] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

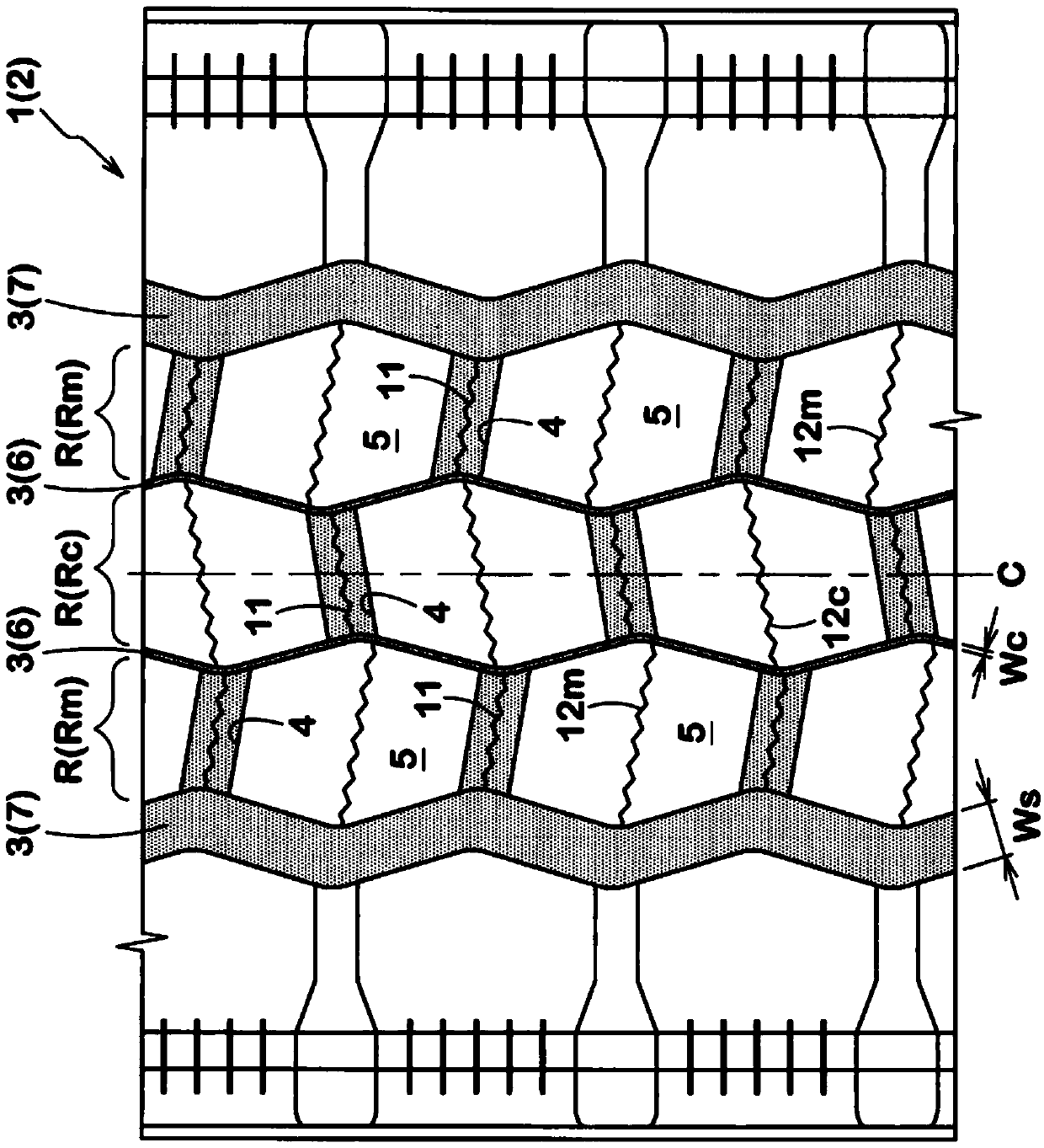

[0045] figure 1 It is a developed view showing the tread portion 2 of the tire 1 according to the embodiment of the present invention. In this embodiment, a case where the tire 1 is formed as a heavy-duty pneumatic tire is shown. However, it can also be formed as various tires such as pneumatic tires for passenger cars, commercial vehicles, etc., and non-pneumatic tires (for example, airless tires) in which pressurized air is not filled inside the tires.

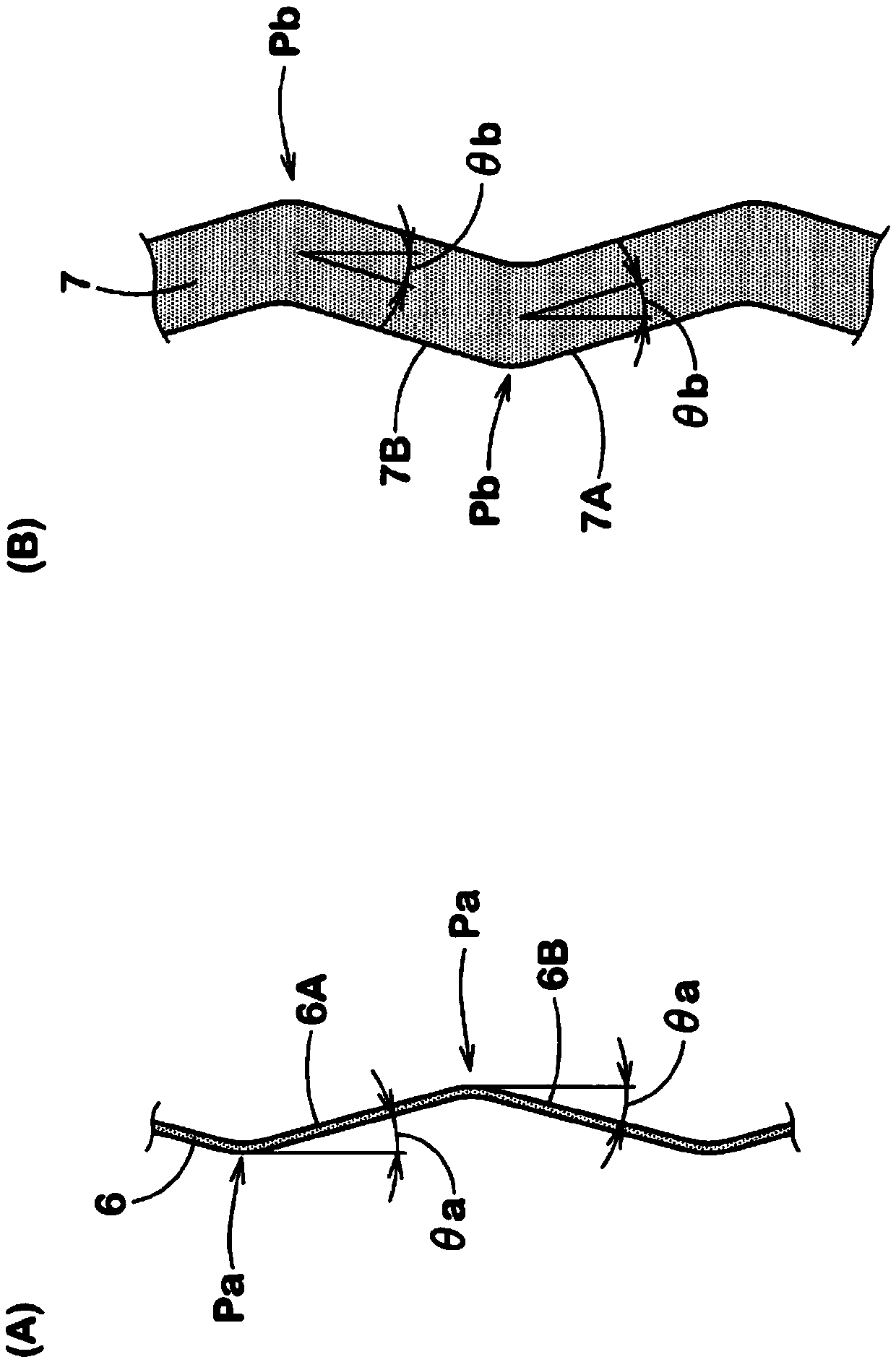

[0046] Such as figure 1 As shown, the tire 1 includes four zigzag circumferential grooves 3 extending in a zigzag shape on the tread portion 2 in the tire circumferential direction. In addition, the tread portion 2 is provided with a transverse groove 4 for connecting between the sawtooth circumferential grooves 3, 3 adjacent in the tire axial direction, whereby the land portion R between the sawtooth circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com