Combined stator with spaced magnetic poles

A combination and magnetic pole technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, winding, etc., can solve the problems of inability to realize pole change and speed change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

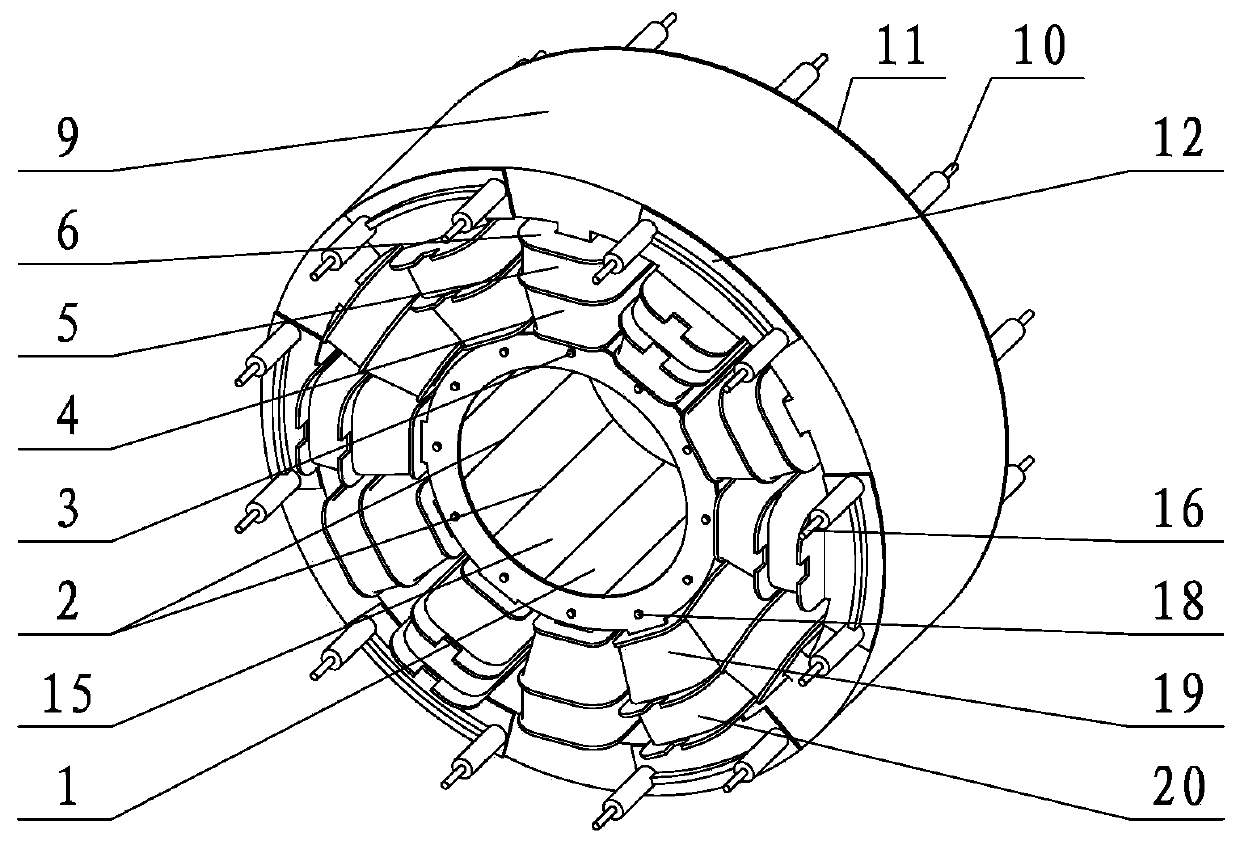

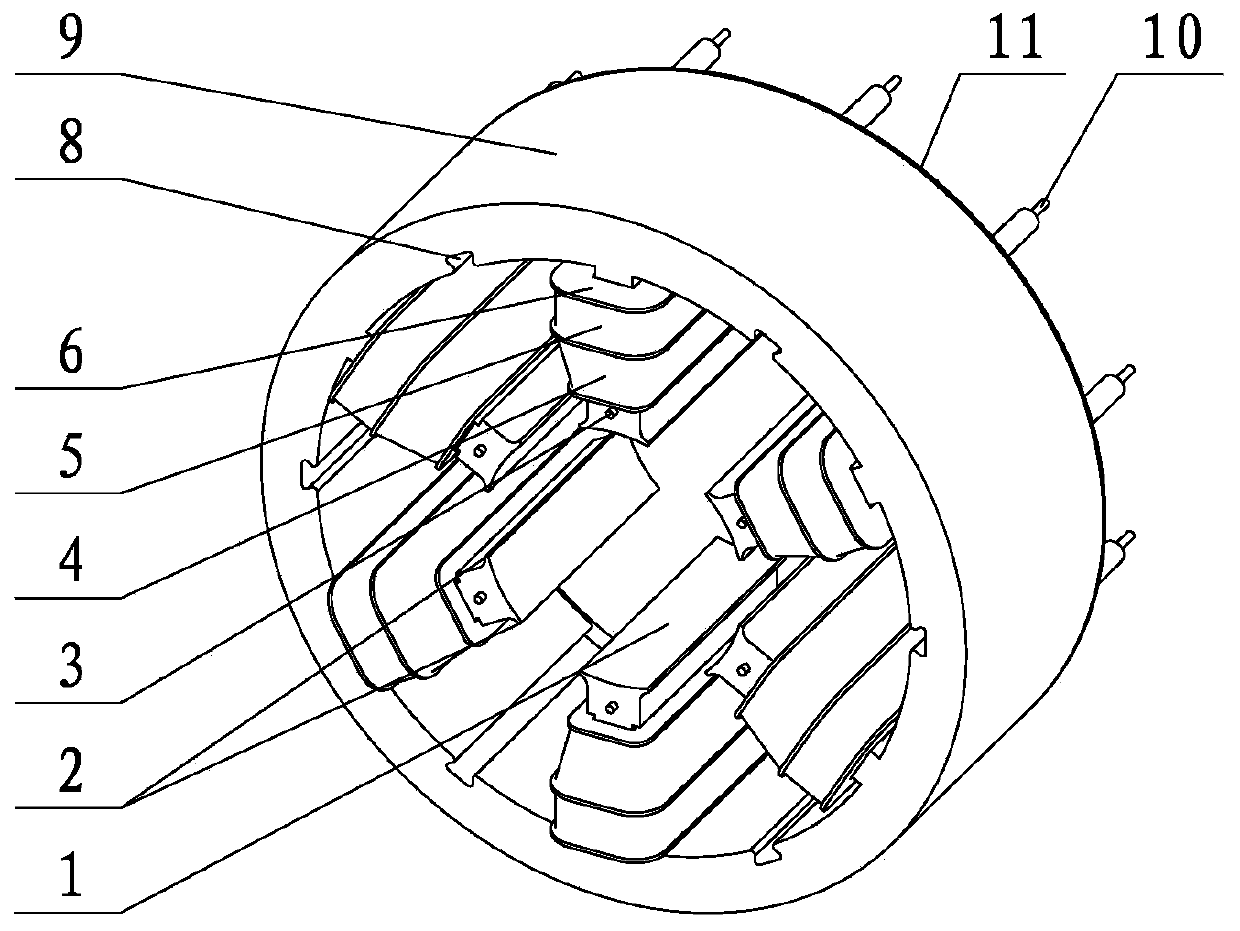

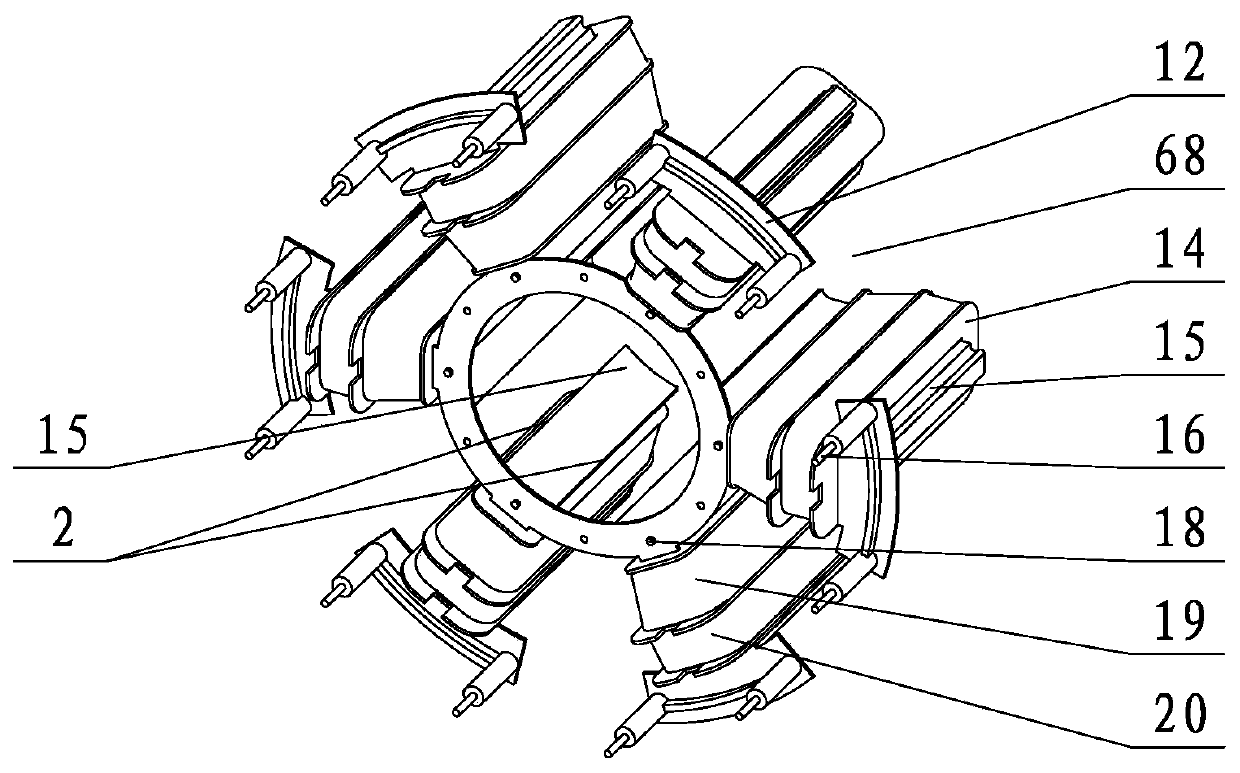

[0054] The present invention will be further described below in conjunction with the drawings.

[0055] Reference figure 1 , figure 2 , image 3 , The combined stator includes a stator component and a stator insert component. The stator component includes a stator iron core 9, a positioning pin 3, a welding pin 10, a toroidal coil bobbin 11, and a coil bobbin 6. The toroidal coil bobbin 11 includes a plurality of positioning coil bobbins 27. Each positioning coil bobbin 27 and coil bobbin 6 has two bobbin slots respectively, and the stator component also includes an inner coil-4 and an outer coil-5. The stator insert parts include a toroidal coil bobbin two 12, a coil bobbin two 14, a magnetic pole insert 15, a welding needle two 16, and a positioning pin two 18. The toroidal coil bobbin two 12 includes several positioning coil bobbin two 40, each positioning coil bobbin two 40 and coil bobbin two 14 have two bobbin wire slots respectively, and the stator insert part also inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com