Cleaning and drying device

A technology of drying equipment and a drying device, which is applied to drying, drying machines, lighting and heating equipment, etc., can solve the problems of inability to clean the surface of steel pipes, incomplete cleaning, and reduce the production efficiency of steel pipes, and achieve simple structure, High degree of automation and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

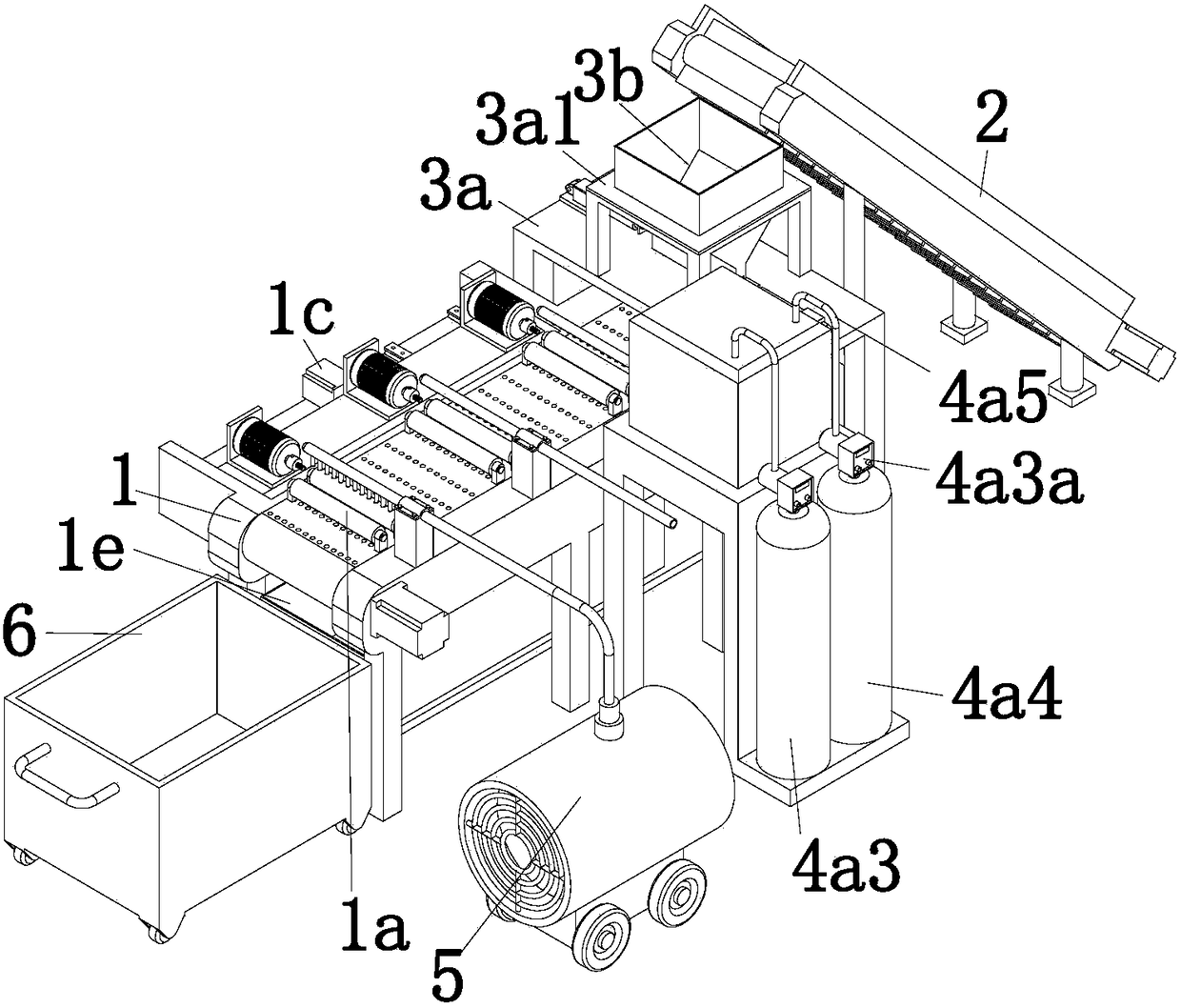

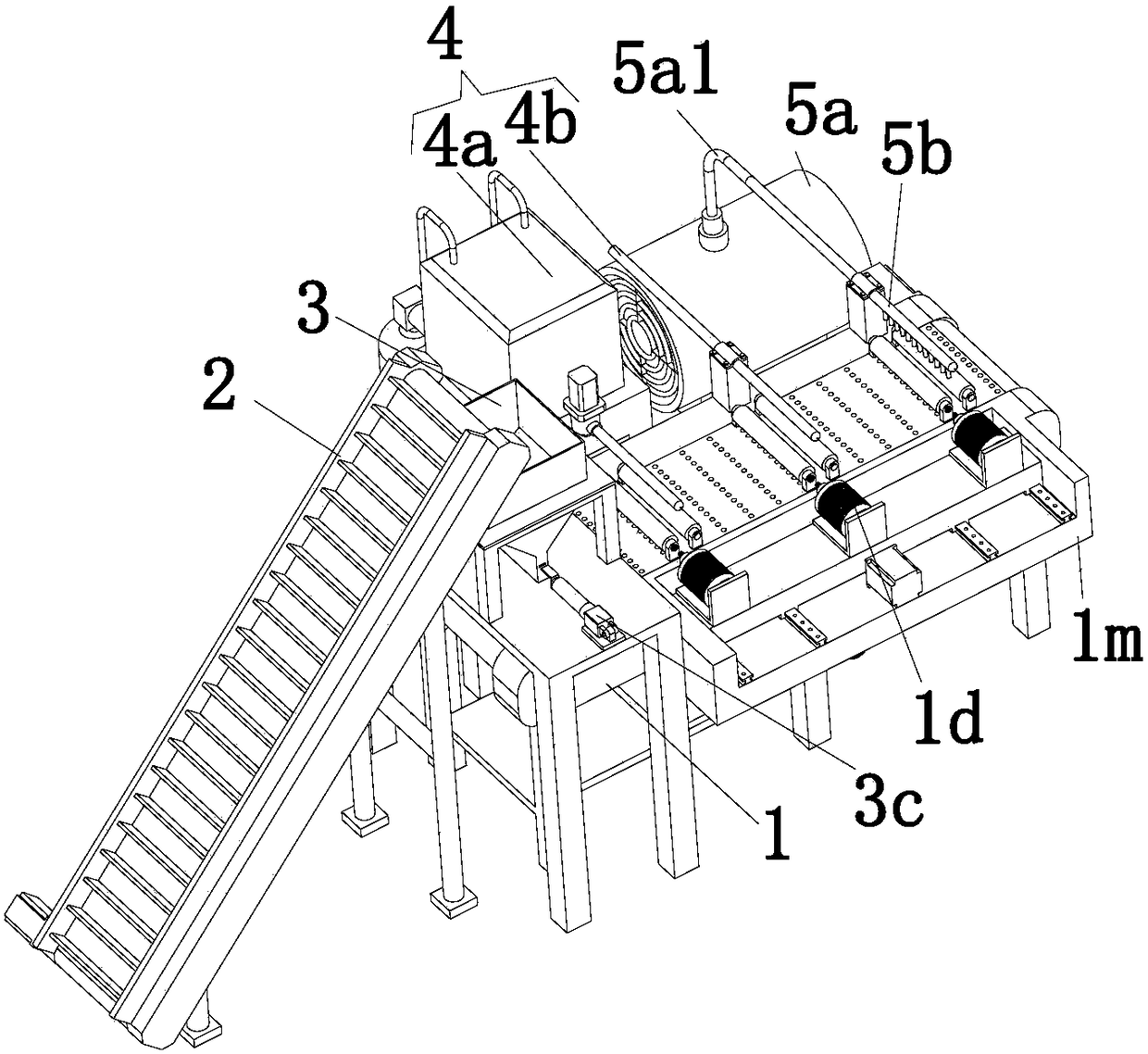

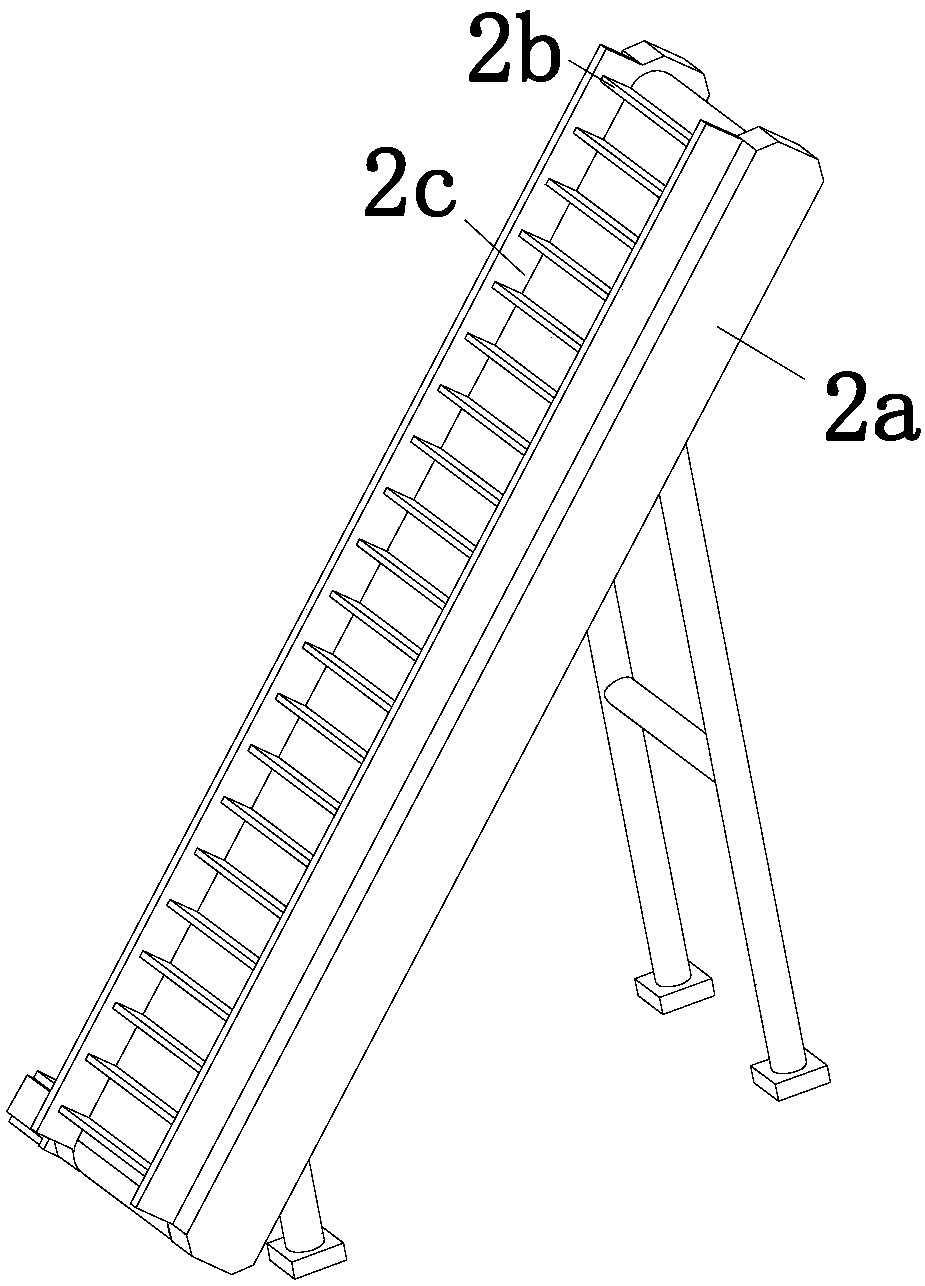

[0031] refer to Figure 1 to Figure 10The shown cleaning and drying equipment includes a conveyor belt 1, a feeding device 2, a feeding device 3, a cleaning device 4, a drying device 5 and a material collection frame 6, and the discharging device 3 includes a first support frame 3a, a hopper 3b and a discharge mechanism 3c for releasing pipes in the hopper 3b, the first support frame 3a is erected on the conveyor belt 1, and the hopper 3b and the discharge mechanism 3c are installed on the first support frame 3a , the feeding device 2 is located on the side of the first support frame 3a, and the conveying surface of the conveyor belt 1 is provided with several positioning jigs 1a and several drainage through holes 1b distributed at equal intervals, and the cleaning The device 4 and the drying device 5 are all locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com