Method for producing a luminescent 3D-radar module cover, and injection-molding assembly

A radar and plastic technology, applied in the direction of household components, applications, optical signals, etc., can solve the problems of canceling radar and interfering with the functions of radar modules, and achieve the effect of low cost and omitting the coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

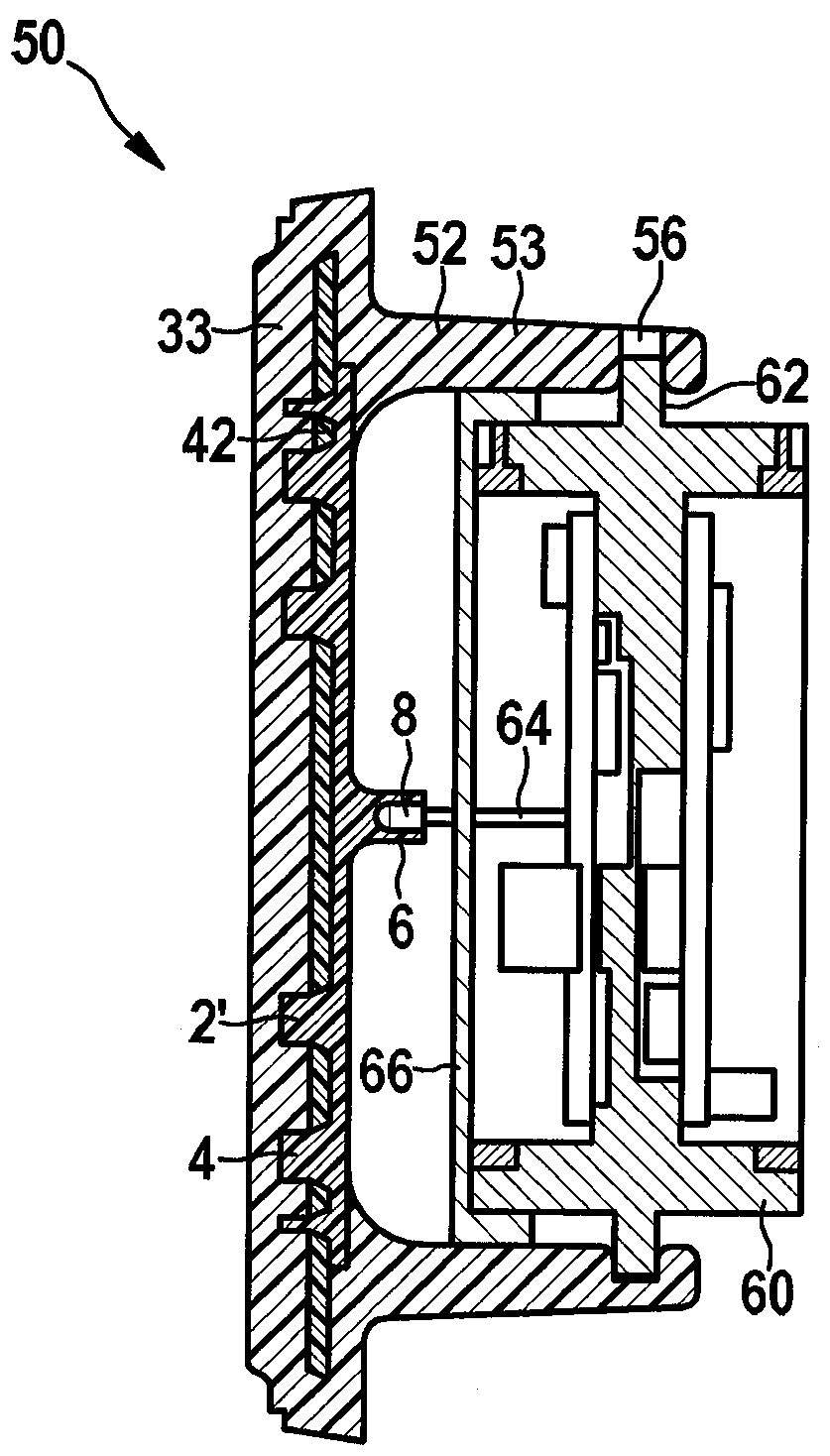

[0041] In all figures, identical or functionally identical elements and devices are provided with the same reference signs, unless otherwise stated.

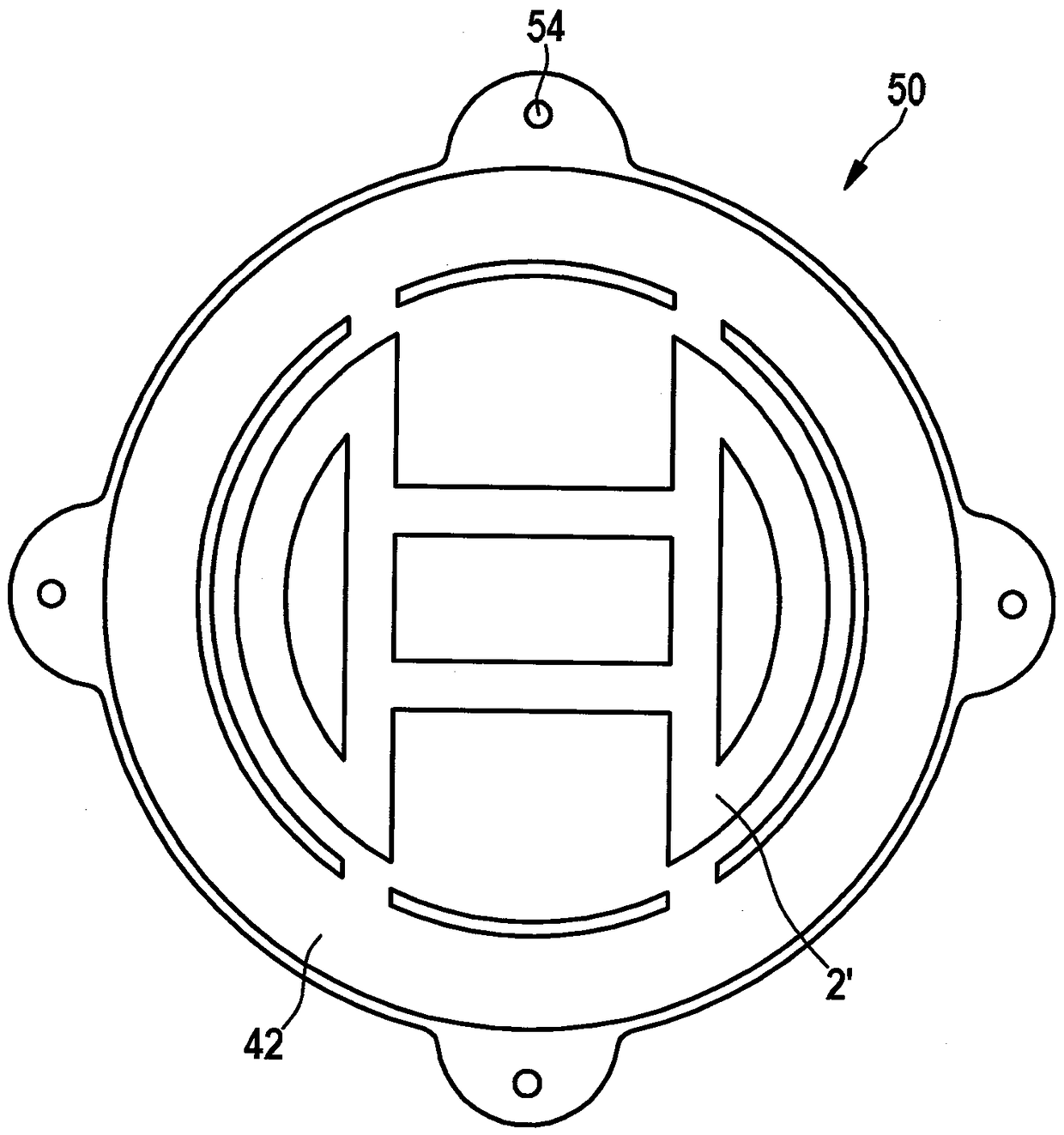

[0042] In general, the various substeps of the method according to the invention and of the injection molding component are illustrated in FIGS. 1 to 5 with the aid of schematic diagrams.

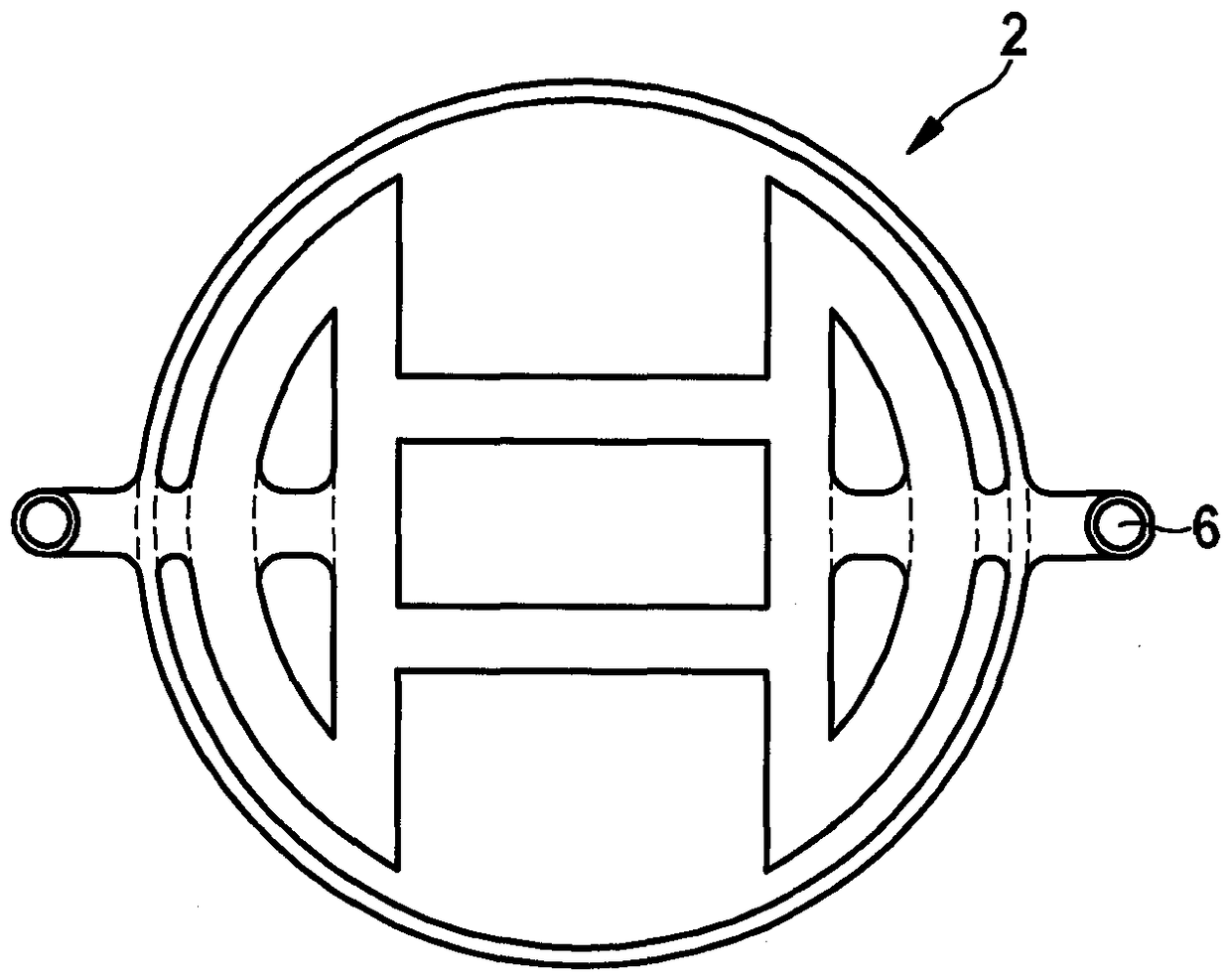

[0043] Here, first in Figure 1a A diagram of the method steps for producing a three-dimensional structure 2 having at least one light guide 4 , which is produced by means of a first injection molding tool 10 from a first light-scattering plastic, is seen in c. here, Figure 1a A three-dimensional structure 2, shown as a molded part of this method step, is accommodated in an injection molding tool 10, where the structure 2 forms a disk-shaped profile, said profile in Figure 1b in, in planar top view and in Figure 1c can be better identified in side view. There, the structure 2 is recognized as a transparent body which has, at two opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com