Heat dissipation double-sided adhesive tape

A technology of double-sided adhesive tape and thermally conductive adhesive layer, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of low heat dissipation capacity and unsatisfactory heat dissipation effect, and achieve improved heat conduction, simple structure, and thin thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

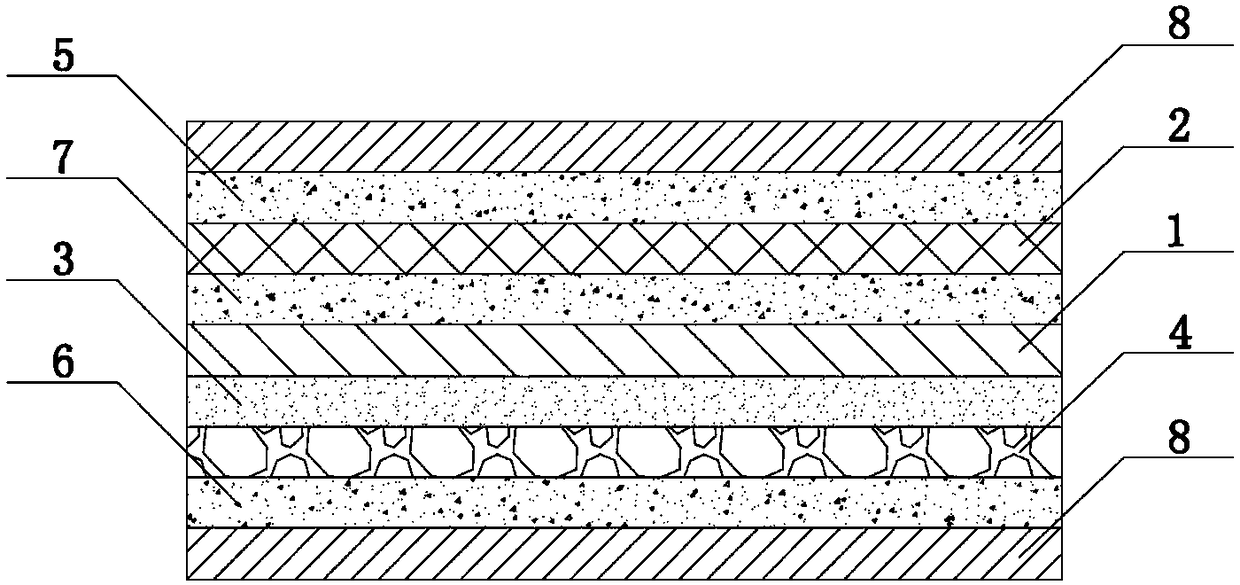

[0021] see figure 1 As shown, it includes a thermally conductive PET substrate, a graphite layer, a silica gel layer, a ceramic layer, a first thermally conductive adhesive layer, and a second thermally conductive adhesive layer. One surface of the thermally conductive PET substrate is compounded with a graphite layer, and the other surface is Composite with a silica gel layer, the silica gel layer is provided with a ceramic layer, the graphite layer is provided with a first thermally conductive adhesive layer, and the ceramic layer is provided with a second thermally conductive adhesive layer. It also includes a third thermally conductive adhesive layer, and the third thermally conductive adhesive layer is arranged between the graphite layer and the thermally conductive PET substrate. The graphite layer is fixedly supported by the first thermally conductive adhesive layer and the third thermally conductive adhesive layer to prevent the graphite sheet from breaking. The thick...

Embodiment 2

[0023] see figure 1 As shown, it includes a thermally conductive PET substrate, a graphite layer, a silica gel layer, a ceramic layer, a first thermally conductive adhesive layer, and a second thermally conductive adhesive layer. One surface of the thermally conductive PET substrate is compounded with a graphite layer, and the other surface is Composite with a silica gel layer, the silica gel layer is provided with a ceramic layer, the graphite layer is provided with a first thermally conductive adhesive layer, and the ceramic layer is provided with a second thermally conductive adhesive layer. It also includes a third thermally conductive adhesive layer, and the third thermally conductive adhesive layer is arranged between the graphite layer and the thermally conductive PET substrate. The graphite layer is fixedly supported by the first thermally conductive adhesive layer and the third thermally conductive adhesive layer to prevent the graphite sheet from breaking. The thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com