Fireproof smoke discharge valve

A technology of smoke exhaust valve and valve plate, which is applied in the direction of lifting valve, valve details, valve device, etc., which can solve the problems that the valve blade cannot be closed and closed flexibly and reliably, wear, shaft deformation, etc. The effect of large and uniform rotation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

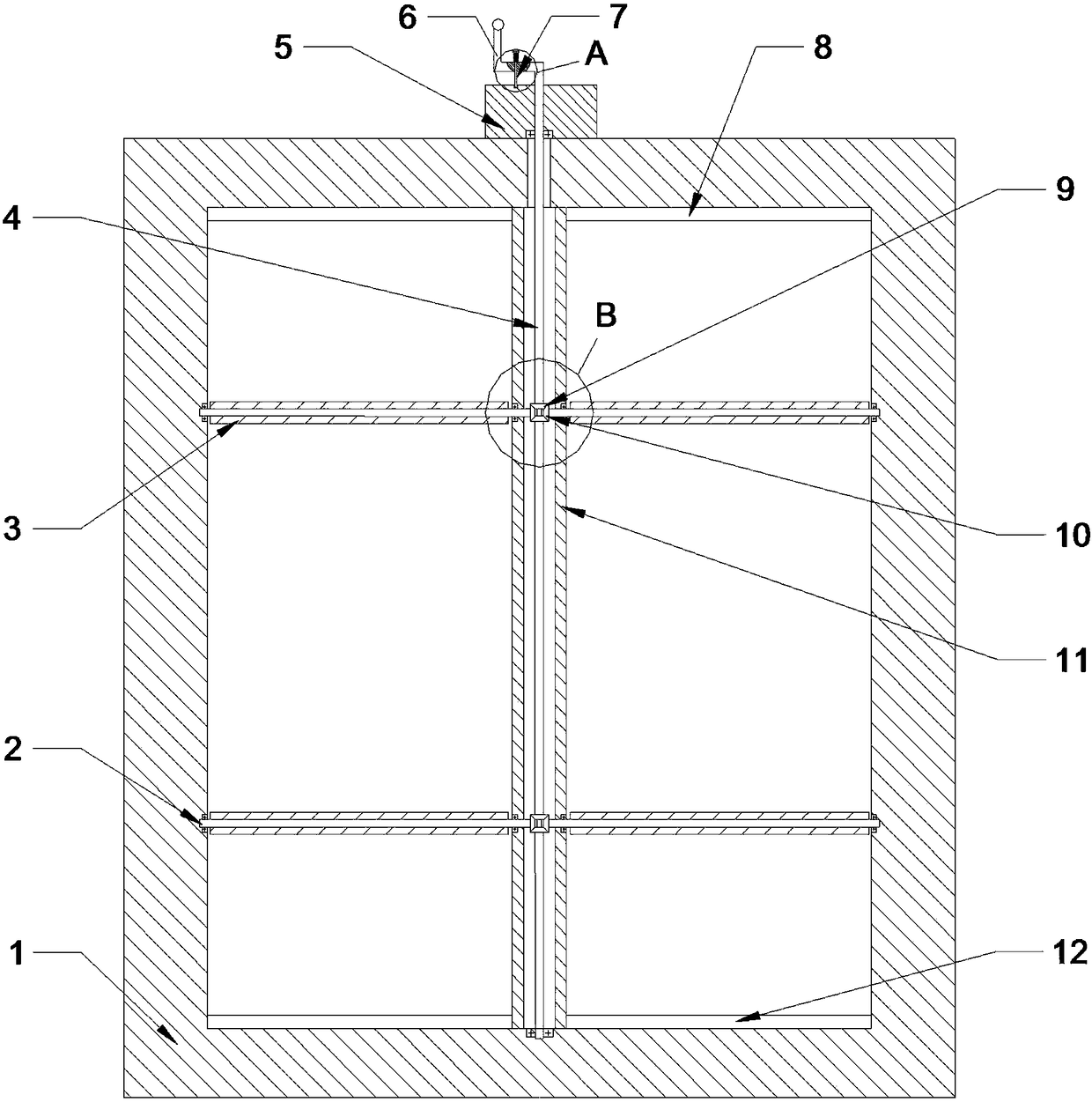

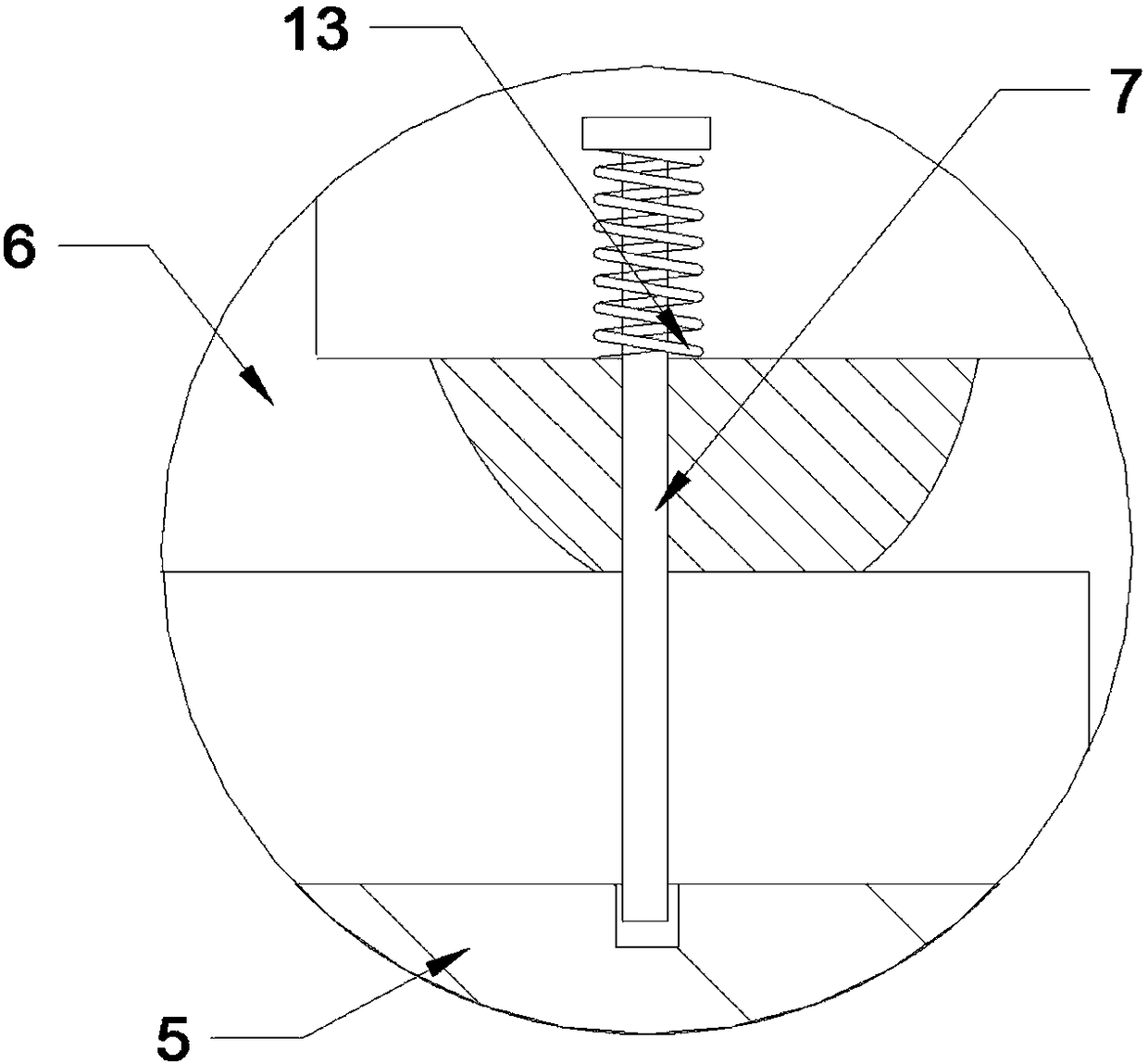

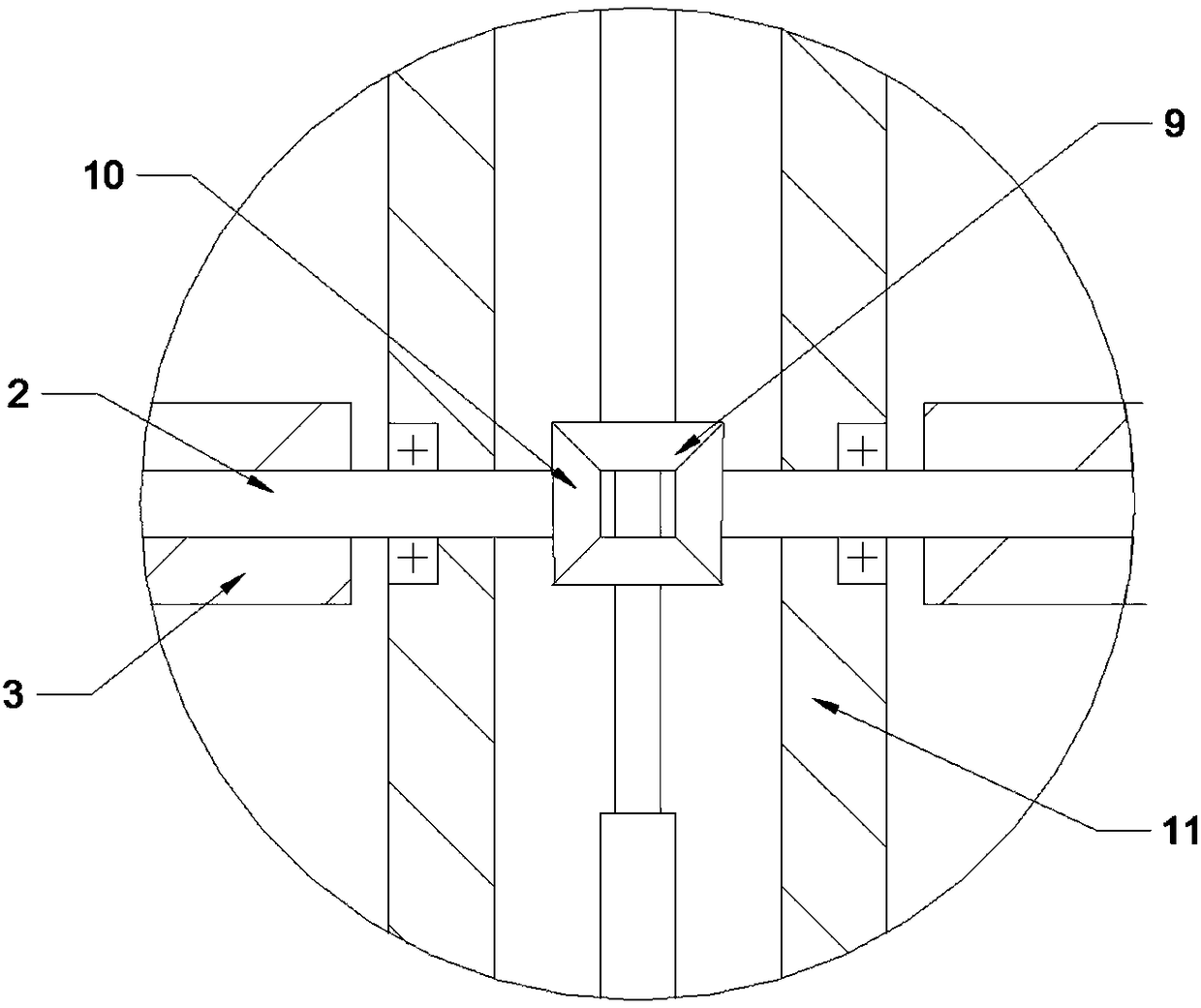

[0034] see Figure 1~5 , a fire and smoke exhaust valve, including a valve body 1, a valve blade 3, a driving shaft 4 and a valve blade rotating shaft 2 are installed on the valve body 1, the driving shaft 4 and the valve blade rotating shaft 2 are perpendicular to each other, and a driving shaft 4 is installed on the driving shaft 4. Bevel gear 9, driven bevel gear 10 is installed on the end of valve disc rotating shaft 2 towards driving shaft 4, driving bevel gear 9 and driven bevel gear 10 mesh with each other, valve blade 3 is installed on valve disc rotating shaft 2.

[0035] In the present invention, when the driving shaft 4 is rotated, the driving bevel gear 9 on the driving shaft 4 drives the driven bevel gear 10 meshed with it to rotate, thereby driving the valve disc rotating shaft 2 to rotate, and the valve blade 3 turns from a horizontal state to a vertical state. Close the outlet on the inner frame of the valve body 1 to achieve the purpose of closing. At the same...

Embodiment 2

[0037] see Figure 1~5 , a fire and smoke exhaust valve, including a valve body 1, a valve blade 3, a driving shaft 4 and a valve blade rotating shaft 2 are installed on the valve body 1, the driving shaft 4 and the valve blade rotating shaft 2 are perpendicular to each other, and a driving shaft 4 is installed on the driving shaft 4. Bevel gear 9, driven bevel gear 10 is installed on the end of valve disc rotating shaft 2 towards driving shaft 4, driving bevel gear 9 and driven bevel gear 10 mesh with each other, valve blade 3 is installed on valve disc rotating shaft 2.

[0038] The valve blade 3 includes a valve plate 3-1, and the valve plate 3-1 is provided with a rotating shaft hole 3-3 through which the valve rotating shaft 2 passes, and the valve plate 3-1 is socketed in the valve plate through the rotating shaft hole 3-3. On the valve disc rotating shaft 2, the valve disc plate 3-1 is fixedly installed on the valve disc rotating shaft 2 through its rotating shaft hole ...

Embodiment 3

[0041] see Figure 1~5 , a fire and smoke exhaust valve, including a valve body 1, a valve blade 3, a driving shaft 4 and a valve blade rotating shaft 2 are installed on the valve body 1, the driving shaft 4 and the valve blade rotating shaft 2 are perpendicular to each other, and a driving shaft 4 is installed on the driving shaft 4. Bevel gear 9, driven bevel gear 10 is installed on the end of valve disc rotating shaft 2 towards driving shaft 4, driving bevel gear 9 and driven bevel gear 10 mesh with each other, valve blade 3 is installed on valve disc rotating shaft 2.

[0042] The valve blade 3 also includes a matching platform 3-2, which is a long plate-shaped body, and its thickness is slightly smaller than that of the valve plate 3-1, and the matching platform 3-2 is installed on the valve plate 3-1. The upper and lower ends of the valve blade 3 are fitted with the fitting platform 3-2, so that the two valve blades 3 form a stepped sealing surface in contact, so as to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com