Friction wheel pressure detecting mechanism and detection method thereof

A detection mechanism and detection method technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems such as the method of detecting pressure without two friction wheels, the inconvenient detection, detection and adjustment of friction wheel pressure, etc. Achieve the effect of eliminating debugging work, saving energy, and concise operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

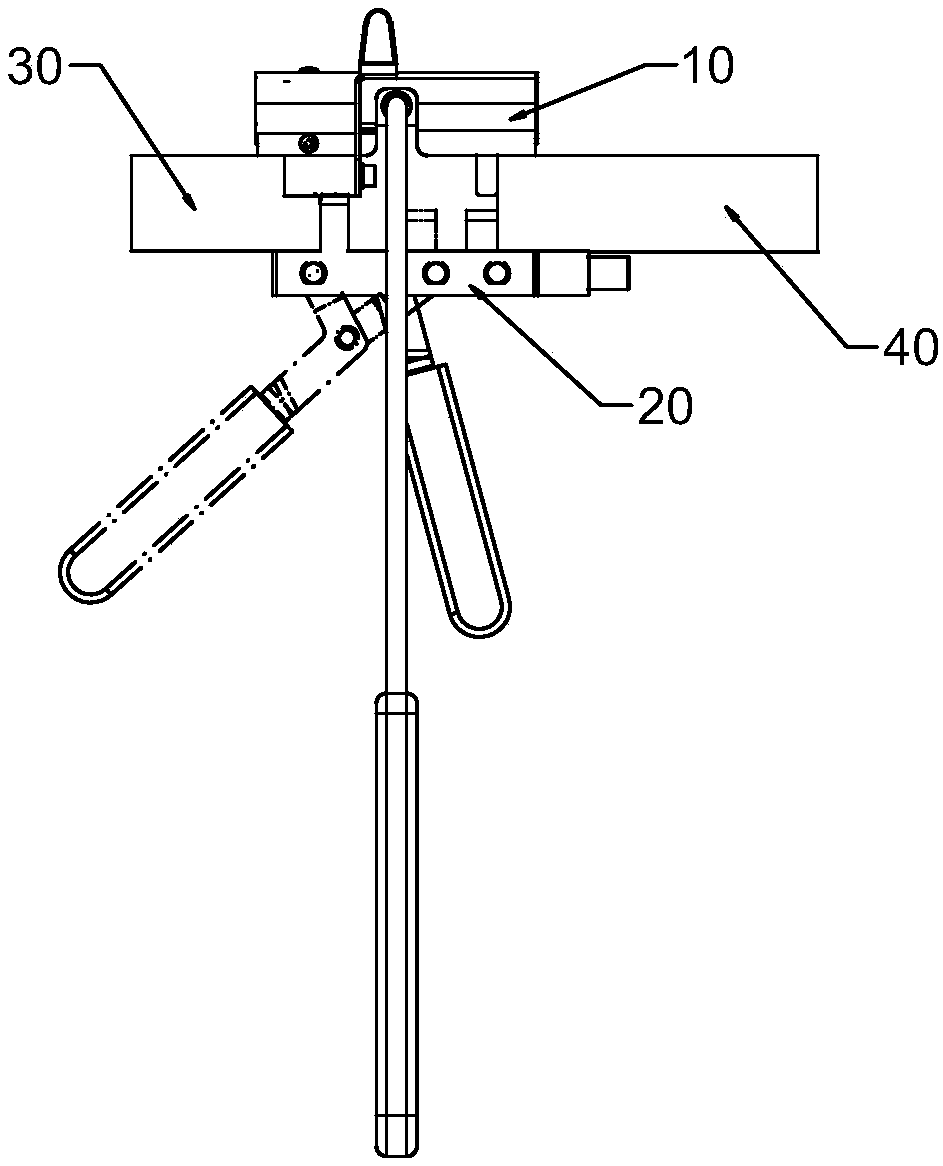

[0020] refer to figure 1 , a friction wheel pressure detection mechanism, including a pressure detection device 10 for detecting the pressure between the first friction wheel and the second friction wheel and a spreader 20 used in conjunction with it, and the spreader 20 makes the first friction The wheel 30 is separated from the second friction wheel 40 , and the pressure between the first friction wheel 30 and the second friction wheel 40 is detected by the pressure detection device 10 after the first friction wheel 30 is separated from the second friction wheel 40 .

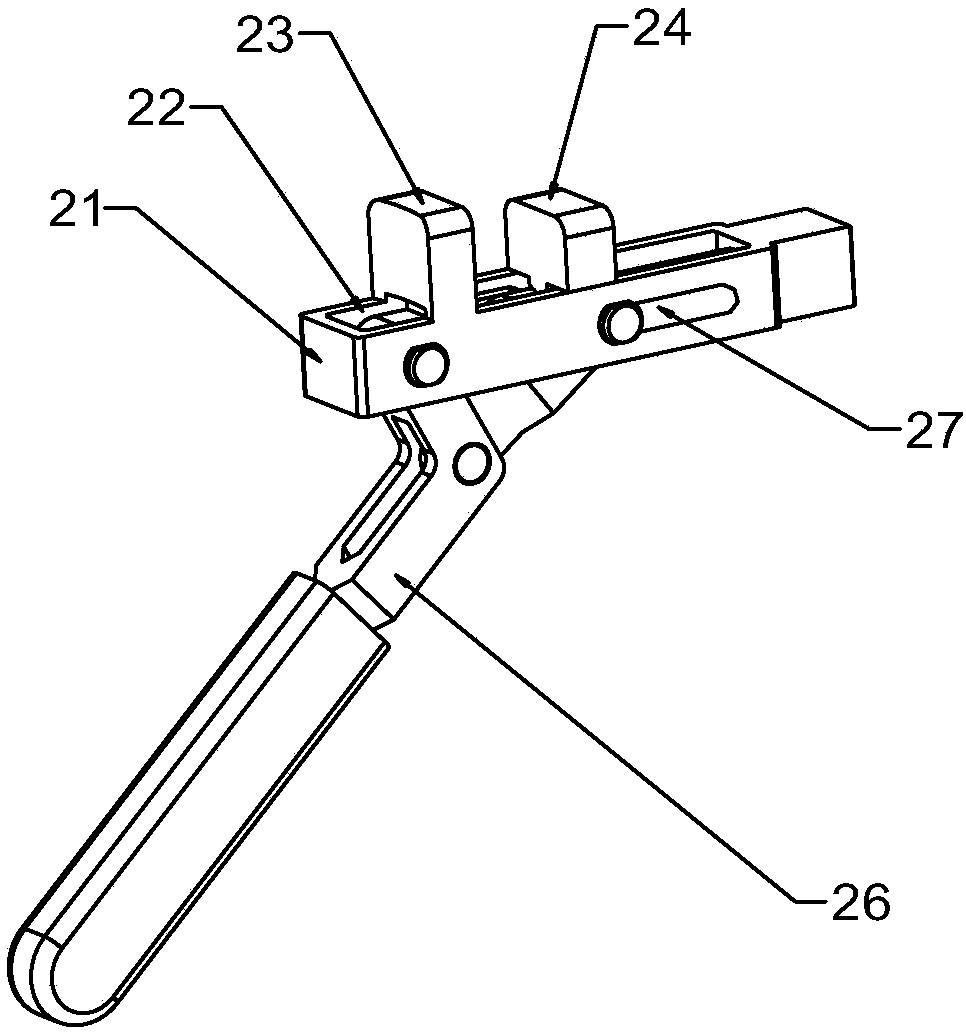

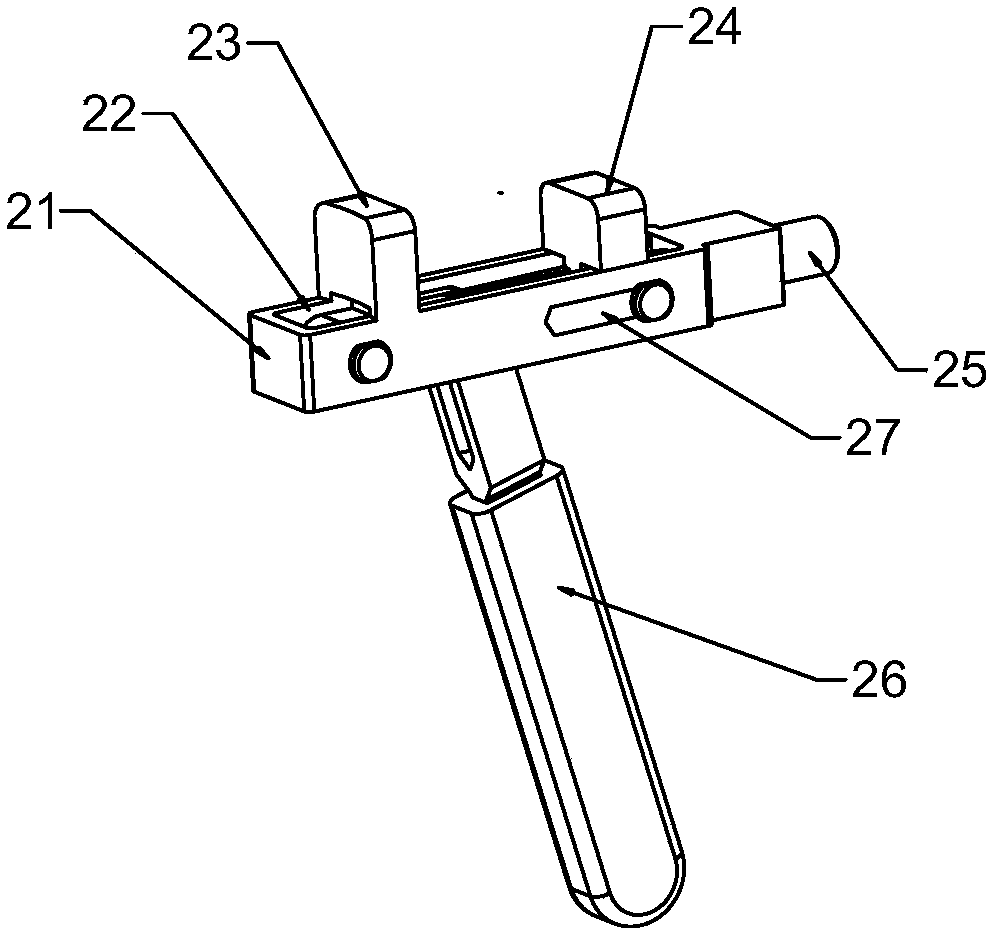

[0021] refer to figure 2 , image 3 Specifically, the spreader 20 includes a strip-shaped support seat 21, and the support seat 21 is provided with a bar-shaped sliding groove 22 that runs through the upper and lower surfaces of the support seat 21, and at one end of the support seat 21 A fixing seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com