Reactor parallel air cooling heat-removal system

A heat dissipation system and reactor technology, applied in the cooling/ventilation of substation/switchgear, electrical components, substation/power distribution device shell, etc., can solve the problems of low reliability, high cost of reactor, heavy weight of reactor, etc. , to achieve the effect of convenient installation and maintenance, high protection level and efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

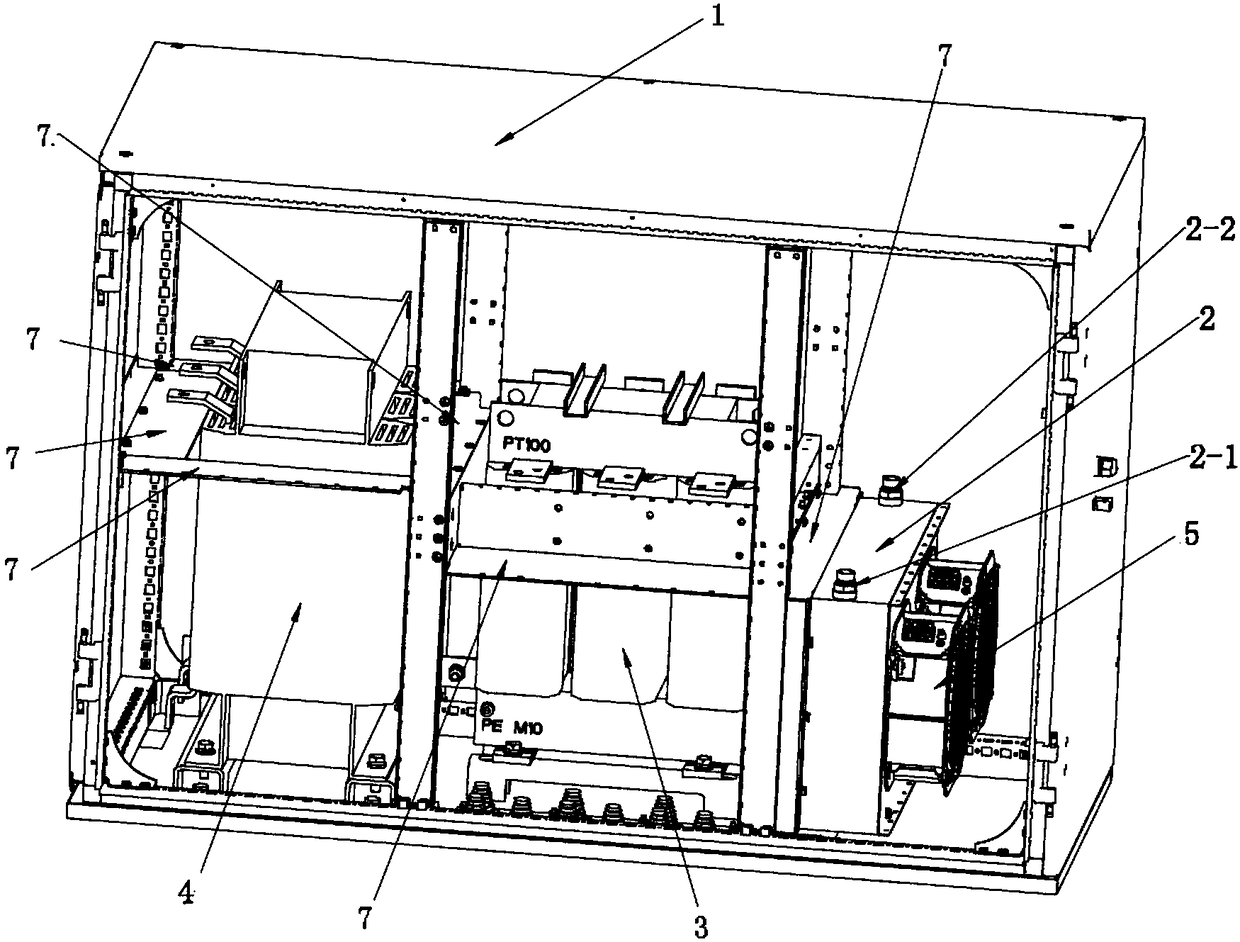

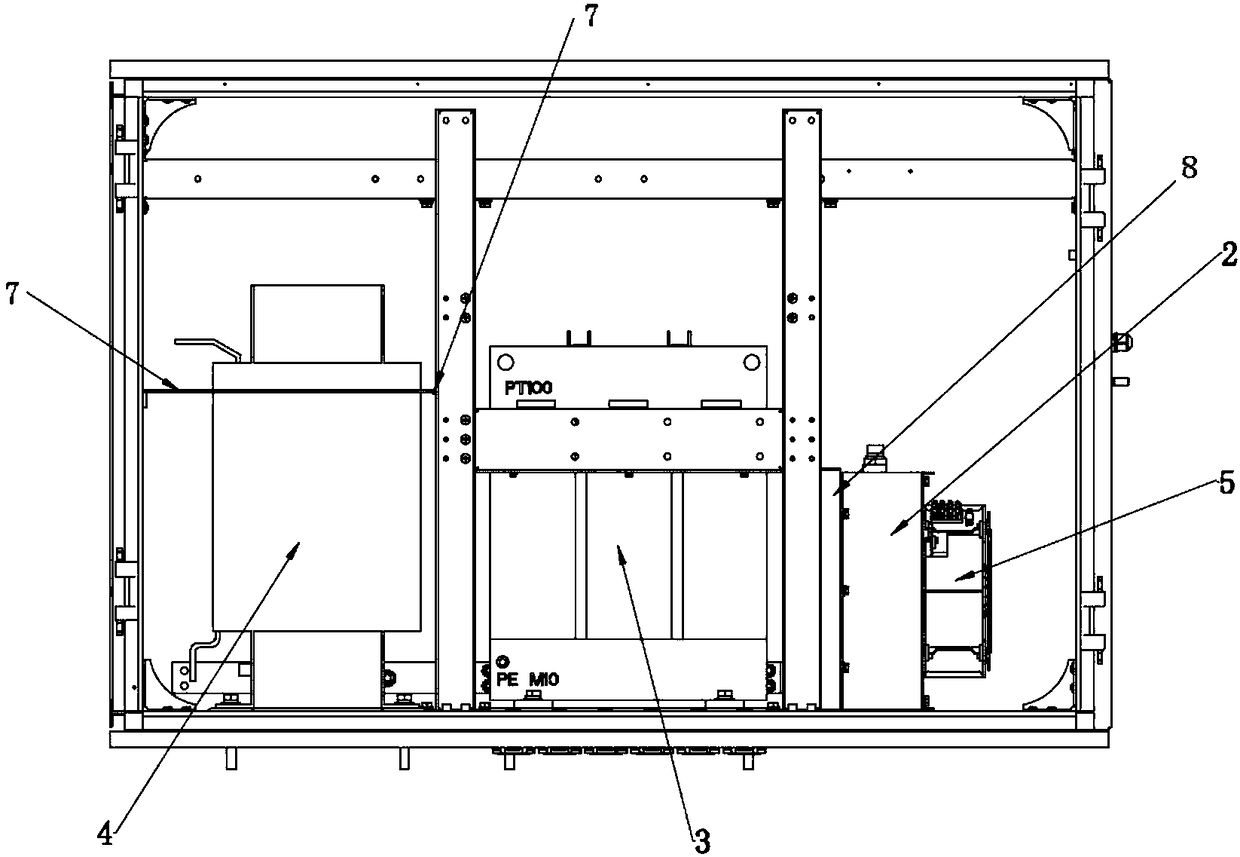

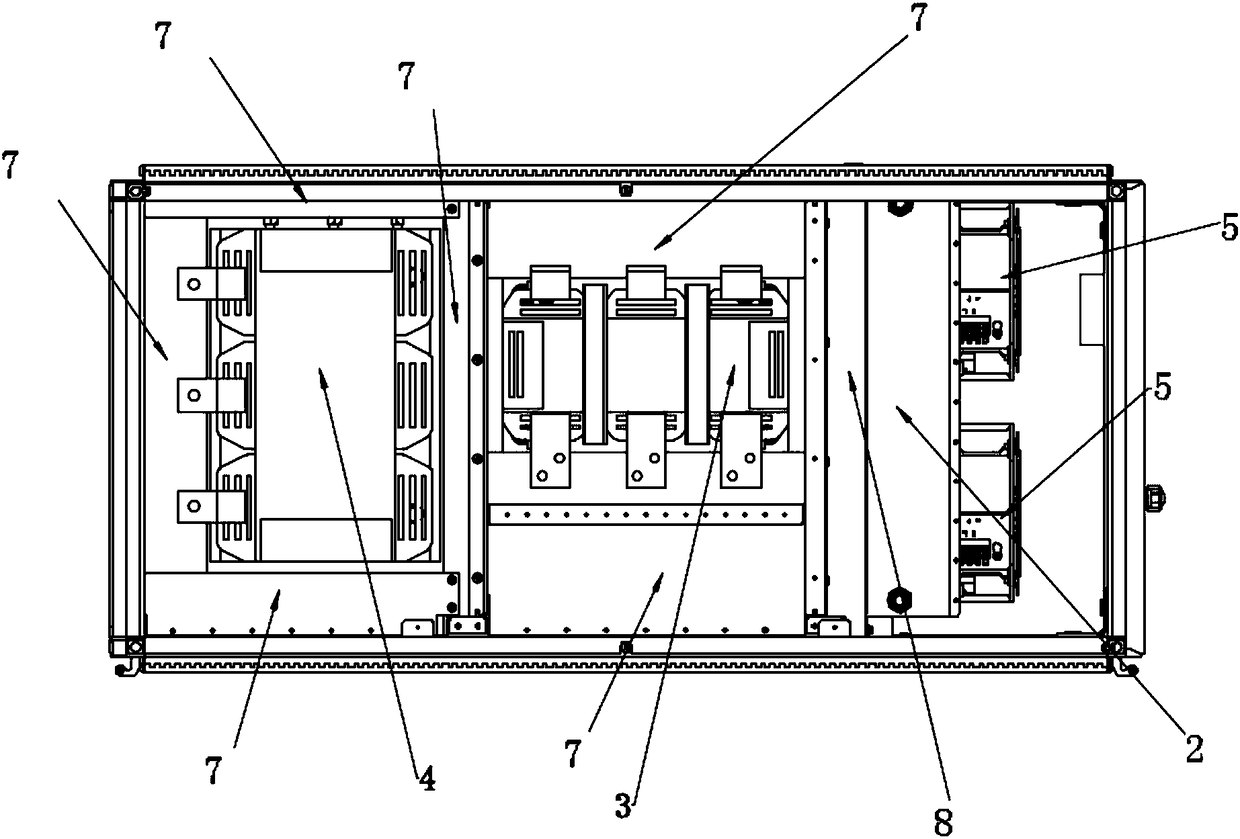

[0021] A reactor parallel air-cooled heat dissipation system, such as Figure 1~4 As shown, including the cabinet 1, the cabinet 1 is equipped with an organic side reactor 3 and a grid side reactor 4, and the generator side reactor 3 and the grid side reactor 4 are adjacent to and arranged in parallel at the bottom of the cabinet 1; it also includes a fan 5 and the water-air heat exchanger 2; the water-air heat exchanger 2 is arranged on the side close to the machine-side reactor 3, and an air cavity 6 is arranged between the water-air heat exchanger 2 and the machine-side reactor 3; the fan 5 is fixed On the water-wind heat exchanger 3, and the air outlet of the fan 5 is facing the air inlet of the water-wind heat exchanger; a wind cavity 8 is formed between the air outlet of the fan 5 and the air inlet of the water-wind heat exchanger 2; The sides of the side reactor 3 and the grid side reactor 4 and the side of the cabinet 1 are provided with several windshields 7 to preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com