Large stroke precision two-stage electric cylinder

A large stroke, electric cylinder technology, applied in the direction of electric components, transmission devices, electromechanical devices, etc., can solve the problems that affect the transmission speed, working accuracy and service life of the electric cylinder, cannot meet the requirements of the working stroke, and the electric cylinder is unstable. , to achieve the effects of small installation space occupation, high reliability and small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

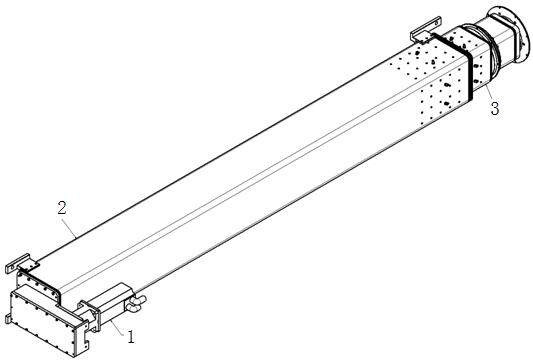

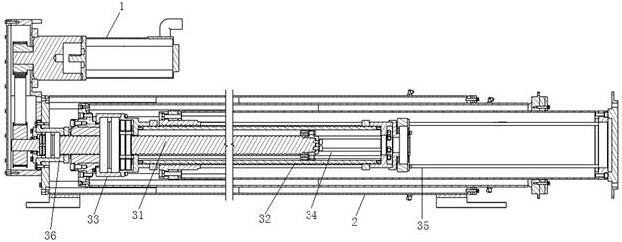

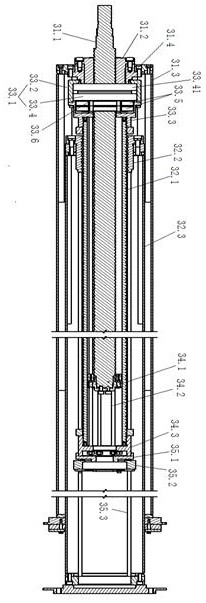

[0026] Combine below Figure 1 to Figure 4 Embodiments of the present invention are described in detail.

[0027] Large-stroke precision two-stage electric cylinder, including two-stage piston assembly 3, electric input assembly 1 that provides power for the expansion and contraction of two-stage piston assembly 3, and cylinder assembly 2 with a square cross section, electric input assembly 1 is fixed on the cylinder assembly 2, the two-stage piston assembly 3 is set in the cylinder assembly 2, one end is in transmission connection with the electric input assembly 1, and the other end passes through the cylinder assembly 2. It is characterized in that the two-stage piston assembly 3 includes an electric The primary screw piston assembly 31 connected to the input assembly 1 and the secondary screw piston assembly 32 coaxially installed in the primary screw piston assembly 31, the primary screw piston assembly 31 and the secondary screw piston assembly 32 Transmission connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com