Textile displaying equipment

A technology for displaying equipment and textiles, applied in display stands, display hangers, display shelves, etc., can solve the problems of textile dust accumulation and inconvenience in taking textiles, and achieve good fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

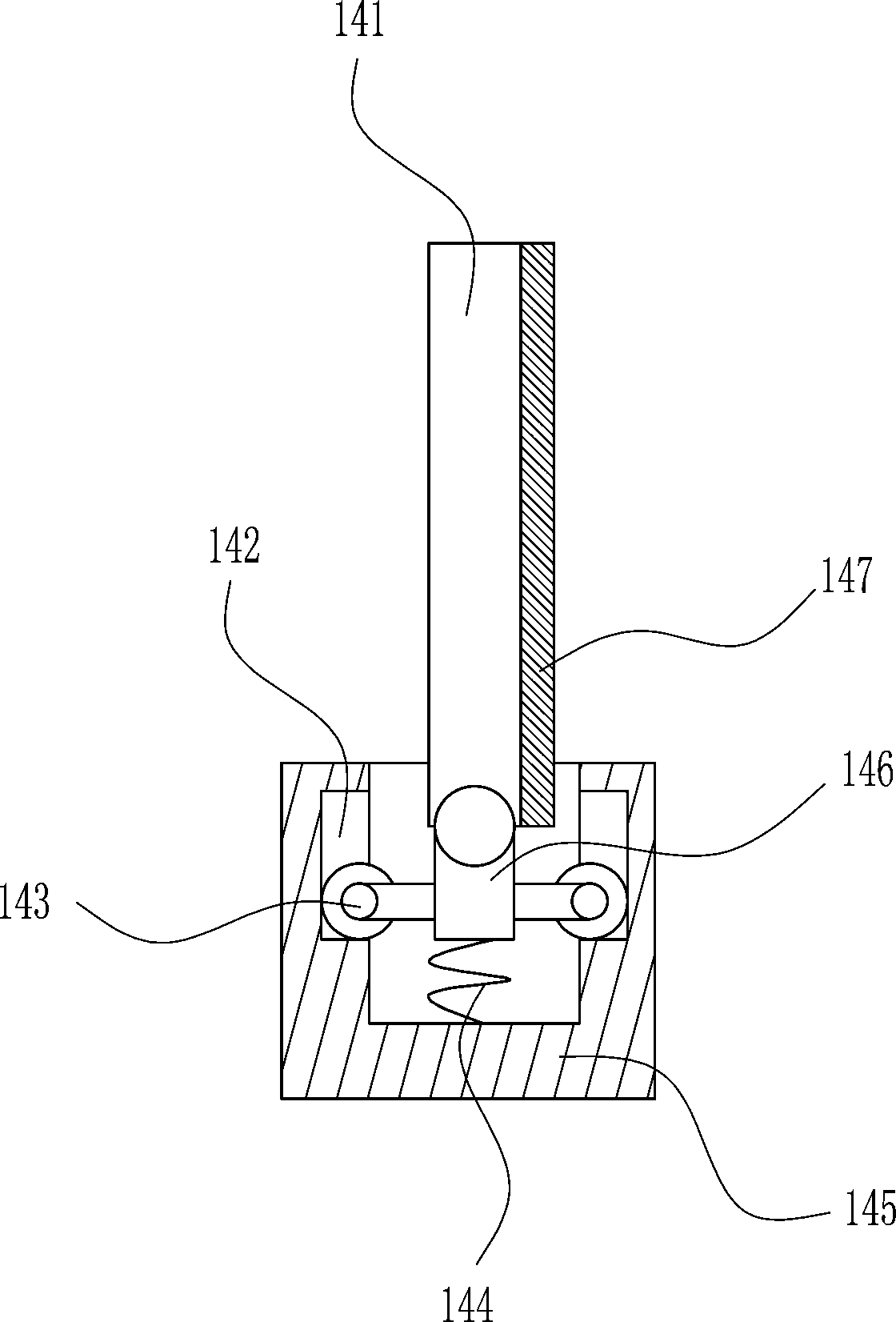

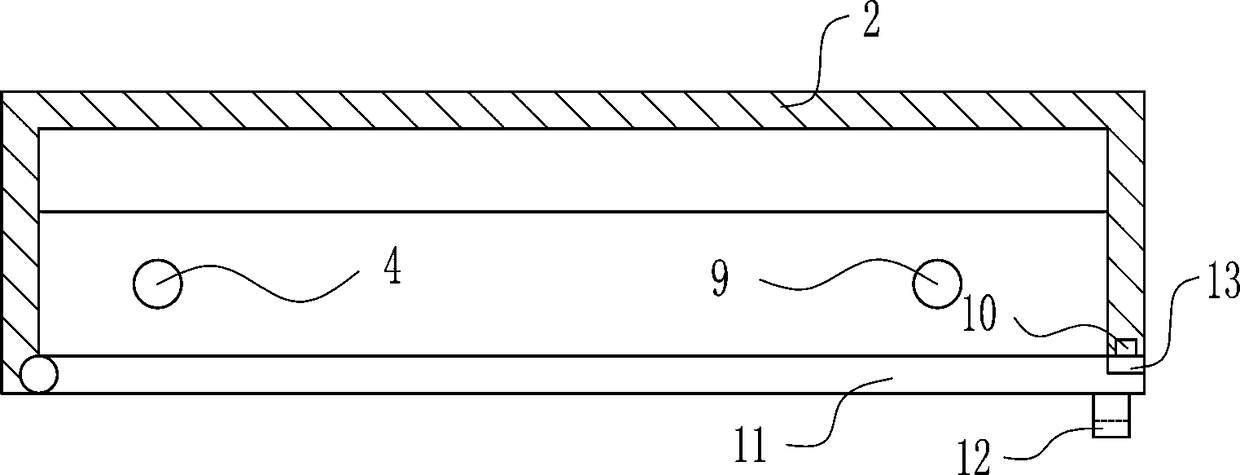

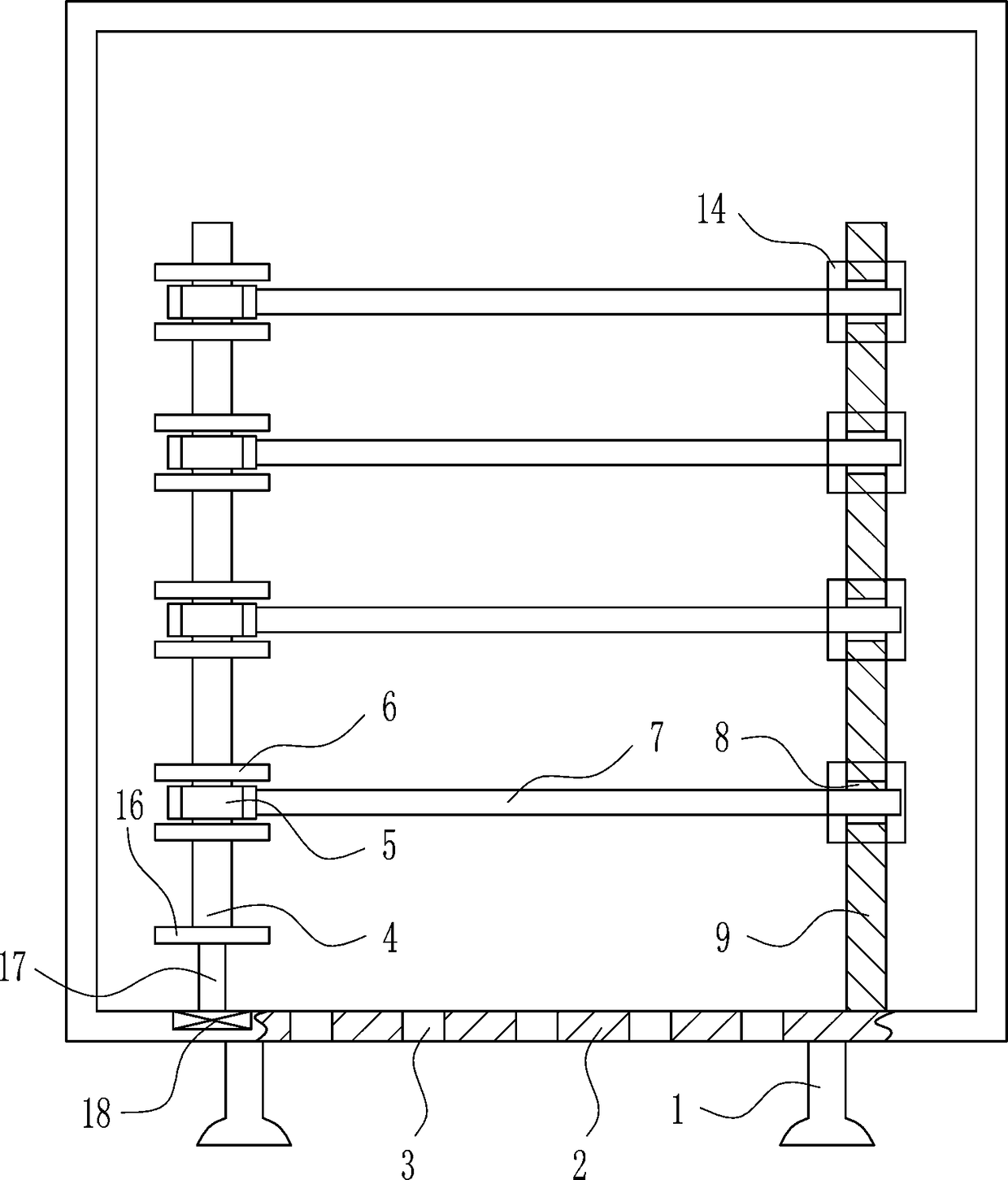

[0030] A textile display device such as Figure 1-8 As shown, it includes a pillar 1, a box body 2, a first pole 4, a swivel ring 5, a limit plate 6, a placement pole 7, a second pole 9, a first magnet block 10, a glass door 11, and a pull ring 12 With the second magnet block 13, the bottom of the box body 2 is symmetrically arranged with pillars 1, the bottom wall of the box body 2 is evenly provided with small holes 3, and the left side of the box body 2 is rotated to be provided with a glass door 11, and the right part of the glass door 11 A draw ring 12 is provided in the front, a second magnet block 13 is provided on the right rear side of the glass door 11, and a first magnet block 10 is provided at the front of the right wall of the casing 2, and the first magnet block 10 cooperates with the second magnet block 13. A first pole 4 and a second pole 9 are arranged on the front side of the inner bottom of the box body 2, the second pole 9 is located on the right side of th...

Embodiment 2

[0032] A textile display device such as Figure 1-8 As shown, it includes a pillar 1, a box body 2, a first pole 4, a swivel ring 5, a limit plate 6, a placement pole 7, a second pole 9, a first magnet block 10, a glass door 11, and a pull ring 12 With the second magnet block 13, the bottom of the box body 2 is symmetrically arranged with pillars 1, the bottom wall of the box body 2 is evenly provided with small holes 3, and the left side of the box body 2 is rotated to be provided with a glass door 11, and the right part of the glass door 11 A draw ring 12 is provided in the front, a second magnet block 13 is provided on the right rear side of the glass door 11, and a first magnet block 10 is provided at the front of the right wall of the casing 2, and the first magnet block 10 cooperates with the second magnet block 13. A first pole 4 and a second pole 9 are arranged on the front side of the inner bottom of the box body 2, the second pole 9 is located on the right side of th...

Embodiment 3

[0035] A textile display device such as Figure 1-8 As shown, it includes a pillar 1, a box body 2, a first pole 4, a swivel ring 5, a limit plate 6, a placement pole 7, a second pole 9, a first magnet block 10, a glass door 11, and a pull ring 12 With the second magnet block 13, the bottom of the box body 2 is symmetrically arranged with pillars 1, the bottom wall of the box body 2 is evenly provided with small holes 3, and the left side of the box body 2 is rotated to be provided with a glass door 11, and the right part of the glass door 11 A draw ring 12 is provided in the front, a second magnet block 13 is provided on the right rear side of the glass door 11, and a first magnet block 10 is provided at the front of the right wall of the casing 2, and the first magnet block 10 cooperates with the second magnet block 13. A first pole 4 and a second pole 9 are arranged on the front side of the inner bottom of the box body 2, the second pole 9 is located on the right side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com