H steel welding process

A welding process and steel plate technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low production efficiency, deviation of welding seam, unable to meet the parallelism of H steel, etc., so as to improve work efficiency and reduce workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

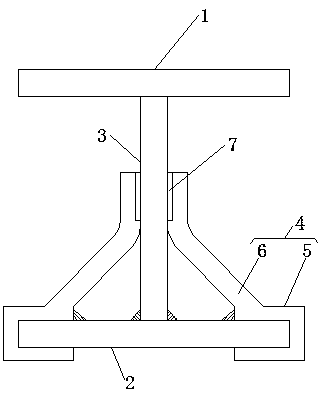

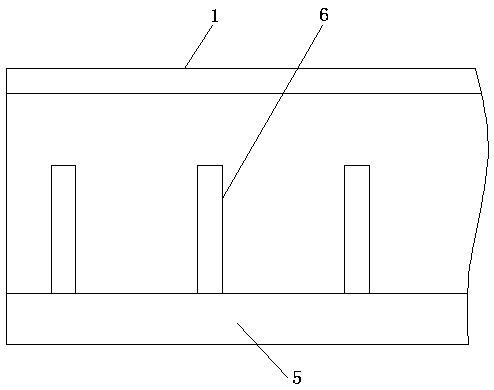

[0024] A kind of H steel welding process is characterized in that comprising the following steps:

[0025] a) Prepare three rectangular steel plates, namely the upper plate, the lower plate and the vertical plate. The vertical plate is a steel plate welded vertically between the upper plate and the lower plate. The upper side is placed vertically along a straight line;

[0026] b) Install fixing clips on both sides of the vertical plate to fix the vertical plate. The fixed clip includes a U-shaped base and an inclined splint. The inclined splint is installed on the U-shaped base, and the U-shaped base is installed on the lower plate. The two ends of the plate are welded to the two ends of the U-shaped base, and the magnet sheet is installed on the inclined splint, and the magnet sheet is attracted to the side of the vertical plate;

[0027] c) Interval spot welding of the weld to be welded between the lower edge of the vertical plate and the upper side of the lower plate;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com