Environment-friendly high-intensity disperse dye composition and preparation method thereof

A technology for disperse dyes and compositions, applied in the direction of organic dyes, etc., can solve the problems of continuous pollution of halogenated aromatic hydrocarbons with high COD, high salt waste water and other problems, and achieve good application prospects, high dyeing strength, and good friction resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

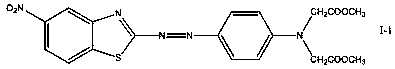

[0040] In a sand mill, add 200 g (structure I-2) compound, add 840 g of water, 500 g of dispersant MF, and 2000 g of glass beads, and sand. After the diffusibility is qualified, filter and spray dry to obtain a yellow disperse dye product.

Embodiment 2

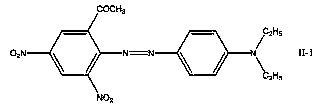

[0044] In a sand mill, add 200 g of (structure II-2) compound, add 840 g of water, 500 g of dispersant MF, and 2000 g of glass beads, and sand. After the diffusibility is qualified, filter and spray dry to obtain a purple disperse dye product.

Embodiment 3

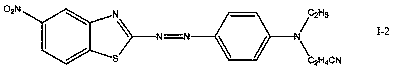

[0048] In a sand mill, add 200 g of (structure III-2) compound, add 840 g of water, 500 g of dispersant MF, and 2000 g of glass beads, and sand. After the diffusibility is qualified, filter and spray dry to obtain a blue disperse dye product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com