Blue reactive dye and preparation method thereof

A reactive dye and dye technology, applied in the field of blue reactive dye and its preparation, can solve the problems of large sewage discharge, unfavorable environmental protection, long process time, etc., and achieve the effects of increased solubility, thorough reaction and high dyeing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

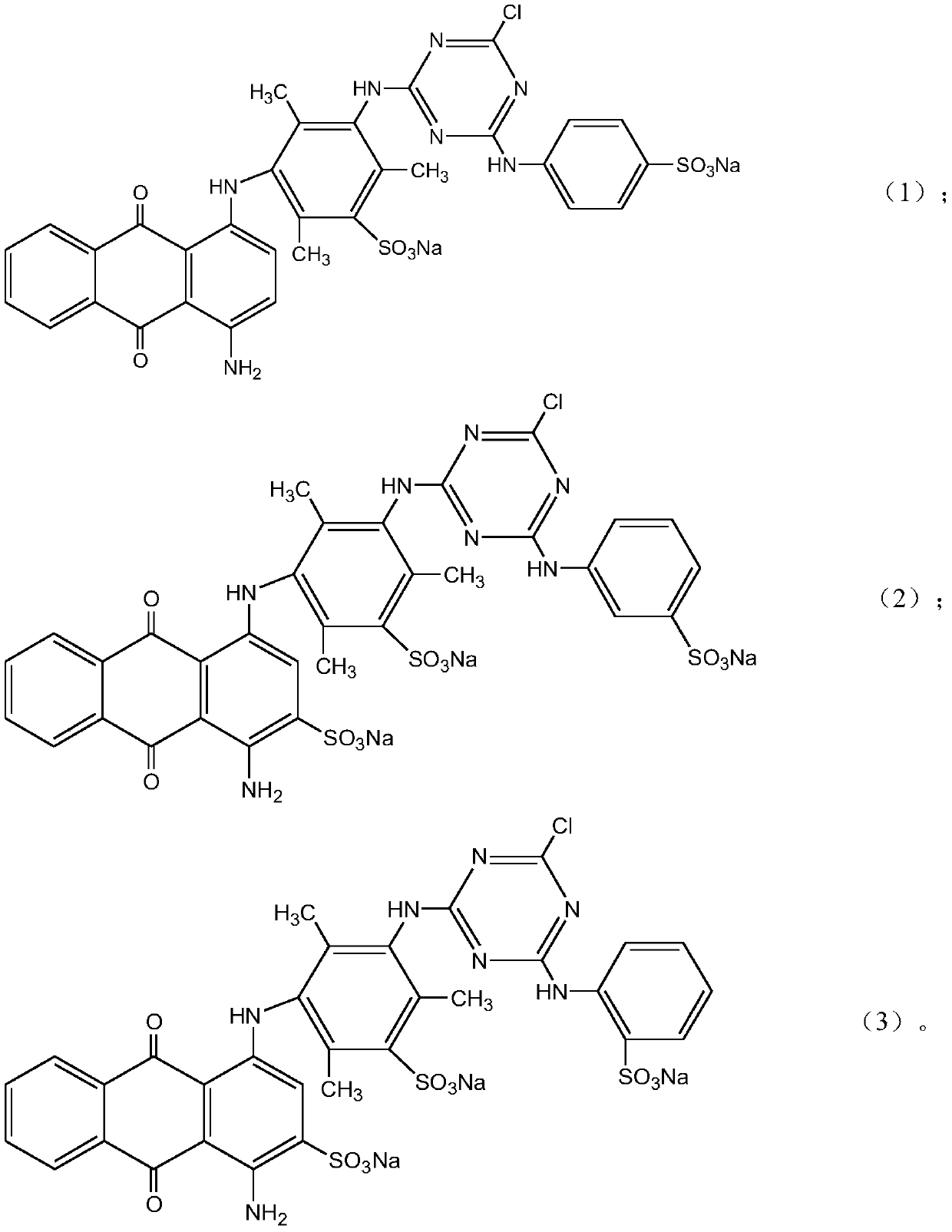

[0026] A kind of blue active dye, its molecular structure is as shown in formula (1):

[0027]

[0028] In the consumption of each component of this blue reactive dye, 1 part represents 0.1mol, and its preparation method comprises the following steps:

[0029] S1. Ullmann Condensation: Dissolve and disperse 1 part of bromonic acid in 100ml of water, heat up to 80°C and disperse for 2 hours, add 200ml of 1.2 parts of M acid (3,5-diamino -2,4,6-trimethylbenzenesulfonic acid) clarified solution, then add 0.05 parts of stannous chloride in percent, and react at a temperature of 85°C for 6 hours to obtain a primary condensate, the primary condensate When HPLC>98%, it is used as the end point of reaction; the reaction equation of Ullman reaction is as follows:

[0030]

[0031] S2. Recovery of M acid: cool the primary condensate in step S1 to 0°C, adjust pH=1-1.5 to precipitate crystalline M acid, filter and squeeze the crystals through a filter press, and recover 0.2 parts o...

Embodiment 2

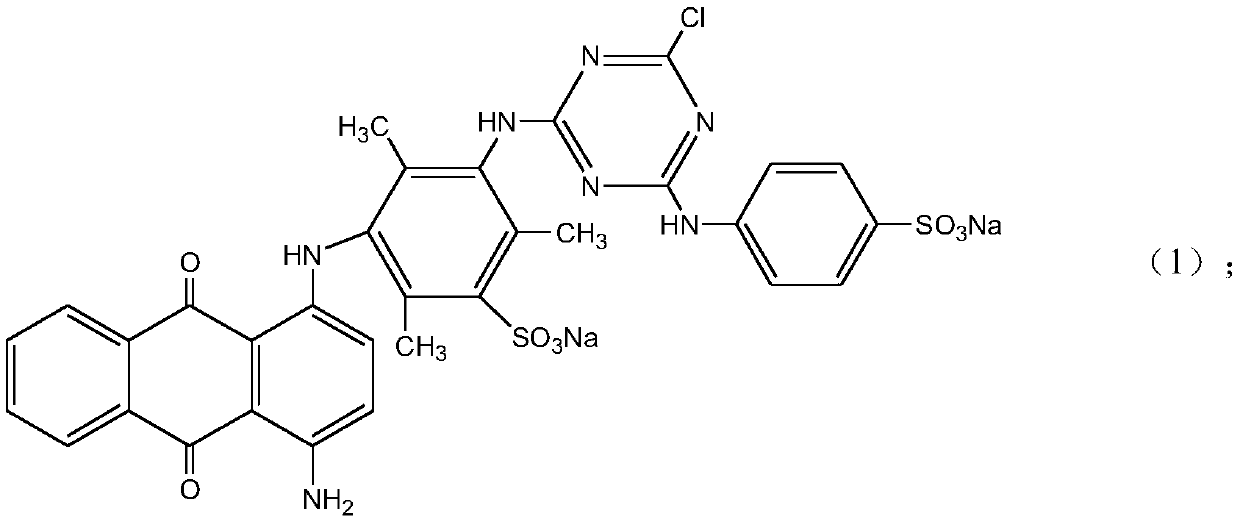

[0038] A kind of blue active dye, its molecular structure is as shown in formula (2):

[0039]

[0040] In the consumption of each component of this blue reactive dye, 1 part represents 0.1mol, and its preparation method comprises the following steps:

[0041] S1. Ullmann condensation: Dissolve and disperse 1 part of bromonic acid in 100ml of water, heat up to 80°C and disperse for 2 hours, add 200ml of 1.2 parts of M acid (3,5-di Amino-2,4,6-trimethylbenzenesulfonic acid) clarified solution, then add 0.05 parts of tin protochloride in percent, react at a temperature of 87°C for 7 hours to obtain a condensate, and use a condensate When the HPLC>98% of the product is used as the reaction end point; the reaction equation of the Ullman reaction is as follows:

[0042]

[0043] S2. Recovery of M acid: cool down the primary condensate in step S1 to 2°C, adjust the pH=1-1.5 to precipitate crystalline M acid, filter through a filter press and squeeze the crystalline M acid, an...

Embodiment 3

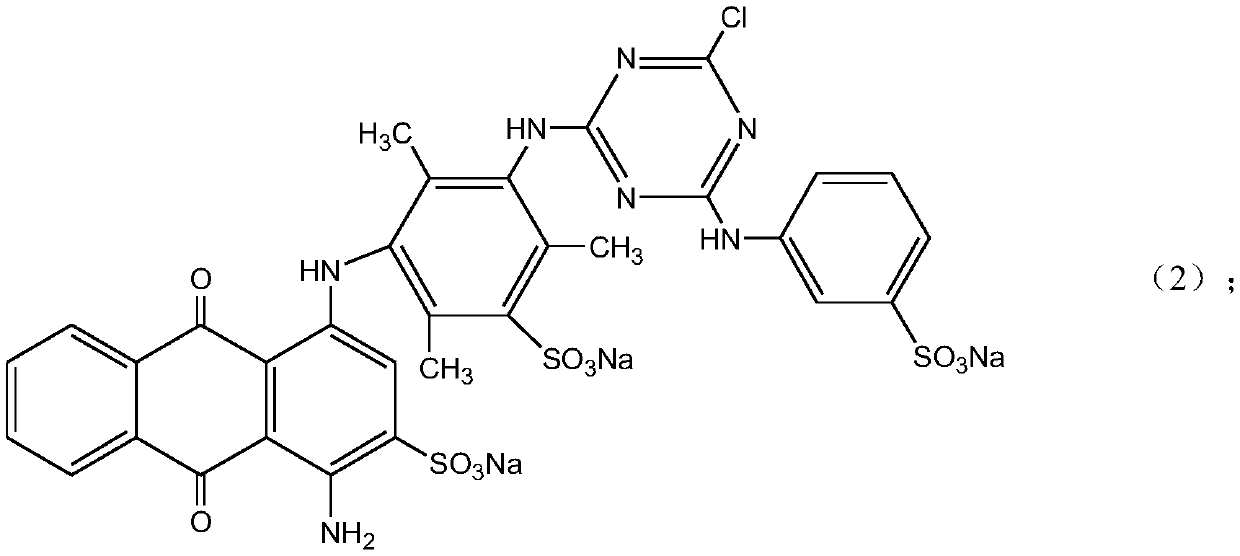

[0050] A kind of blue active dye, its molecular structure is as shown in formula (3):

[0051]

[0052] In the consumption of each component of this blue reactive dye, 1 part represents 0.1mol, and its preparation method comprises the following steps:

[0053] S1. Ullmann condensation: Dissolve and disperse 1 part of bromonic acid in 100ml of water, heat up to 80°C and disperse for 2 hours, then add 200ml of 1.2 parts of M acid (3,5- Diamino-2,4,6-trimethylbenzenesulfonic acid) clarified solution, add 0.05 parts of tin protochloride in percent, and react at a temperature of 90°C for 8 hours to obtain a primary condensation product, to obtain a primary condensation When the HPLC>98% of the product is used as the reaction end point; the reaction equation of the Ullman reaction is as follows:

[0054]

[0055] S2. Recover M acid: cool down the primary condensate in step S1 to 4°C, adjust pH=1-1.5 to precipitate crystalline M acid, filter and squeeze crystalline M acid thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com