Preparation method of vat dark blue BO capable of reducing discharge of the three wastes

An emission, dark blue technology, applied in the direction of dibenzoxanthrone/isobenzoxanthrone dyes, etc., can solve the problems of complex process steps, three-waste pollution, large water consumption, etc., to speed up the reaction rate and improve the dyeing performance. , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

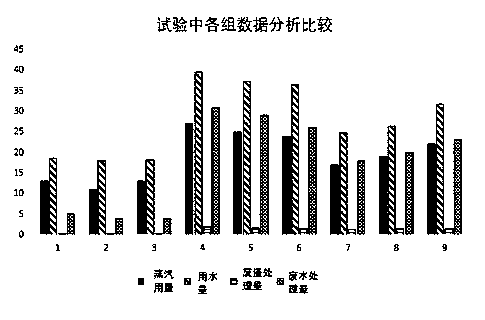

Image

Examples

Embodiment 1

[0014] A method for preparing reduced dark blue BO capable of reducing the discharge of three wastes, comprising the following steps:

[0015] (1) Weigh 0.5 kg of europium oxide and 1.5 kg of silicon oxide, grind and mix them, place them in a resistance furnace preheated to 330°C, raise the temperature to 750°C at a rate of 7°C / min, keep the heat for 90 minutes, and cool naturally to After room temperature, the modified composite ceramic powder is obtained by grinding, the condensation kettle is cleaned and dried, and 450 kg of triethylene glycol and the prepared modified composite ceramic powder are added into the kettle from the metering tank. The particle size of the modified composite ceramic powder is Between 10-15 nanometers; start stirring, put 72 kg of anhydrous sodium acetate and 520 kg of potassium hydroxide into a 2000L condensation pot in turn under stirring conditions, heat up to 103°C with 0.24MPa steam to liquefy the alkali for 45 minutes, let the alkali Fully m...

Embodiment 2

[0019] A method for preparing reduced dark blue BO capable of reducing the discharge of three wastes, comprising the following steps:

[0020] (1) Weigh 0.55kg of europium oxide and 1.8kg of silicon oxide, grind and mix them, place them in a resistance furnace preheated to 340°C, raise the temperature to 760°C at a rate of 7.5°C / min, keep the heat for calcination for 95 minutes, and cool naturally to Grinding after room temperature to obtain modified composite ceramic powder, the particle size of the modified composite ceramic powder is between 10-15 nanometers, the condensation kettle is cleaned and dried, and 455 kilograms of triethylene glycol is added into the kettle from a metering tank to prepare The obtained modified composite ceramic powder was started to stir, and under stirring conditions, 73 kg of anhydrous sodium acetate and 525 kg of potassium hydroxide were successively put into a 2000L condensation pot, and heated to 104°C with 0.25MPa steam to make alkali for 48...

Embodiment 3

[0024] A method for preparing reduced dark blue BO capable of reducing the discharge of three wastes, comprising the following steps:

[0025](1) Weigh 0.6 kg of europium oxide and 2.0 kg of silicon oxide, grind and mix them, place them in a resistance furnace preheated to 350 °C, raise the temperature to 780 °C at a rate of 8 °C / min, keep the heat for 100 minutes, and cool naturally to After grinding at room temperature, the modified composite ceramic powder is obtained. The particle size of the modified composite ceramic powder is between 10-15 nanometers. The condensation kettle is cleaned and dried, and 460 kilograms of triethylene glycol and the prepared Modified composite ceramic powder, start stirring, put 74 kg of anhydrous sodium acetate and 530 kg of potassium hydroxide into a 2000L condensation pot in turn under stirring conditions, use 0.26MPa steam to heat up to 105°C for 50 minutes to dissolve the alkali, let the alkali fully melt , the temperature is raised to 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com