Method for improving production efficiency of vat dark blue BO

A production efficiency, dark blue technology, applied in chemical instruments and methods, organic dyes, anthracene dyes, etc., can solve the problems of large production input, complex process steps, low production efficiency, etc., to reduce losses, speed up reaction rate, performance Balanced improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

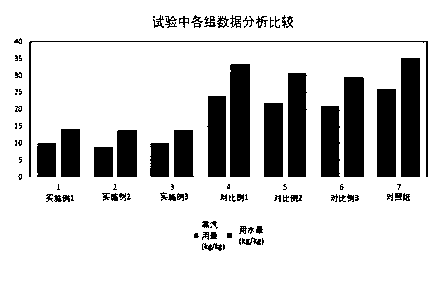

Examples

Embodiment 1

[0022] A method for improving the production efficiency of reduced dark blue BO, using three synthetic methods of triethylene glycol, primary mother liquor, and secondary mother liquor to carry out simultaneously, comprising the following steps:

[0023] Step 1: While synthesizing the triethylene glycol process, add 1077 liters of mother liquor from the metering tank to the mother liquor secondary concentration kettle, distill out 485 liters of water under reduced pressure, and add the material to the condensation kettle, start stirring, and 36 kg of Water sodium acetate and 255 kg of potassium hydroxide are successively put into a 2000L condensation pot, heated to 115°C with 0.24Mpa steam for 45 minutes to heat up to 126°C for later use;

[0024] The invention also provides the processing technology of the triethylene glycol process as follows: washing and drying the condensation kettle, adding 450 kilograms of triethylene glycol from the metering tank to the kettle, starting ...

Embodiment 2

[0035] A method for improving the production efficiency of reduced dark blue BO, using three synthetic methods of triethylene glycol, primary mother liquor, and secondary mother liquor to carry out simultaneously, comprising the following steps:

[0036] Step 1: While synthesizing the triethylene glycol process, add 1078 liters of mother liquor from the metering tank to the mother liquor secondary concentration kettle, distill 488 liters of water under reduced pressure, and add the material to the condensation kettle, start stirring, and 37 kg of Water sodium acetate and 258 kg of potassium hydroxide are successively put into a 2000L condensation pot, heated to 118°C with 0.25Mpa steam for 48 minutes to heat up to 128°C for later use;

[0037] Step 2: Add 1155 liters of secondary mother liquor from the metering tank to the mother liquor secondary concentration kettle, and add 578 liters of water after decompression distillation to the condensation kettle, start stirring, and 31...

Embodiment 3

[0048] A method for improving the production efficiency of reduced dark blue BO, using three synthetic methods of triethylene glycol, primary mother liquor, and secondary mother liquor to carry out simultaneously, comprising the following steps:

[0049] Step 1: While synthesizing the triethylene glycol process, add 1080 liters of mother liquor from the metering tank to the mother liquor secondary concentration kettle, distill 500 liters of water under reduced pressure, and then add the material to the condensation kettle, start stirring, and 38 kg of Water sodium acetate and 260 kg of potassium hydroxide are successively put into a 2000L condensation pot, heated to 120°C with 0.26Mpa steam for 50 minutes to heat up to 130°C for later use;

[0050] Step 2: Add 1160 liters of secondary mother liquor from the metering tank to the secondary concentration kettle of mother liquor, and add 580 liters of water after decompression distillation to the condensation kettle, start stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com