Plastic fused mass color-mixture device of plastic pipe extruder

A technology for plastic pipes and extruders, which is applied in the direction of tubular objects, other household appliances, household appliances, etc., and can solve the problems of air marks and shadows on the product surface, underutilized colorants, and reduced colorant utilization efficiency. Achieve the effect of solving obvious air marks and shadow problems, solving uneven texture, and increasing utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings and specific embodiments.

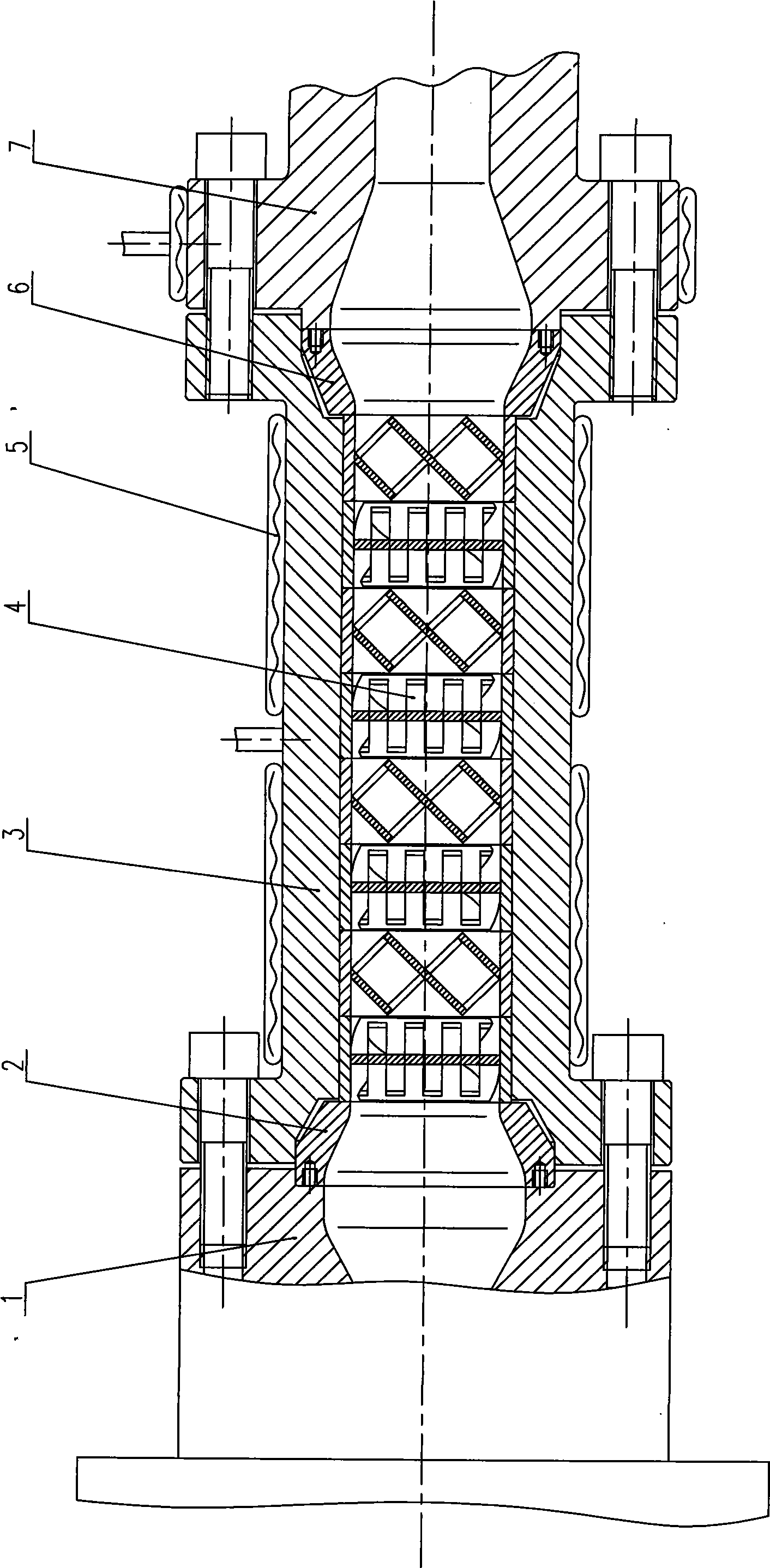

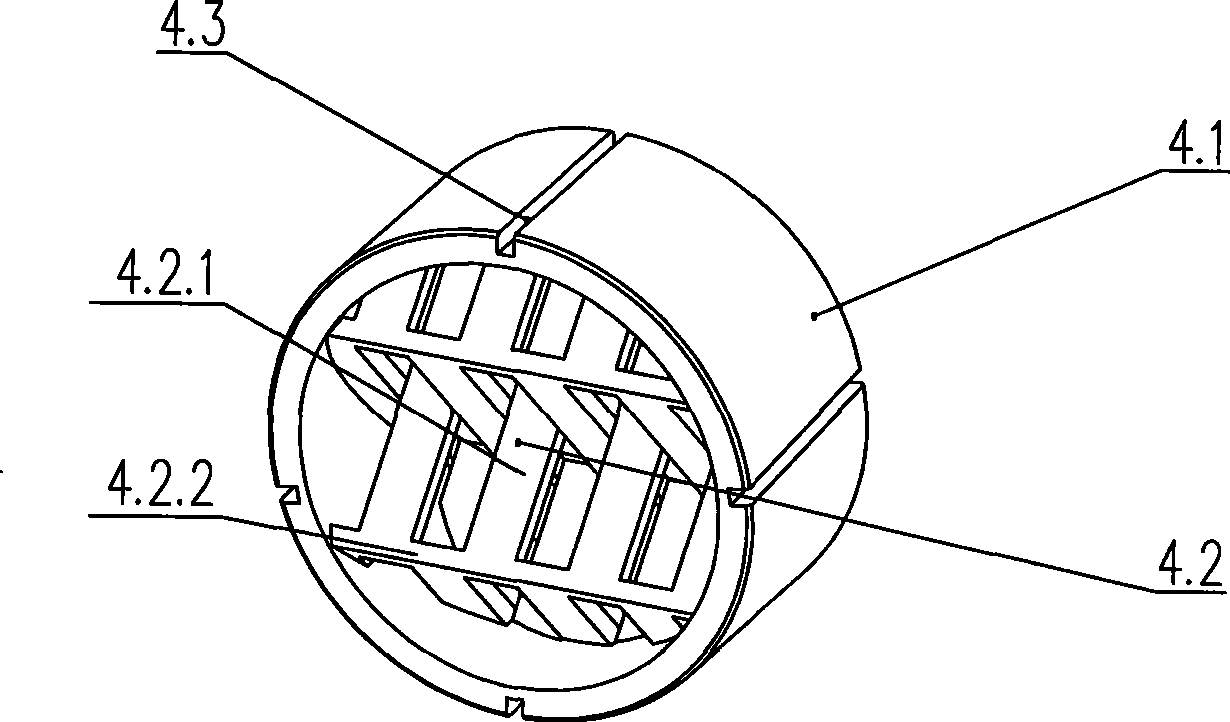

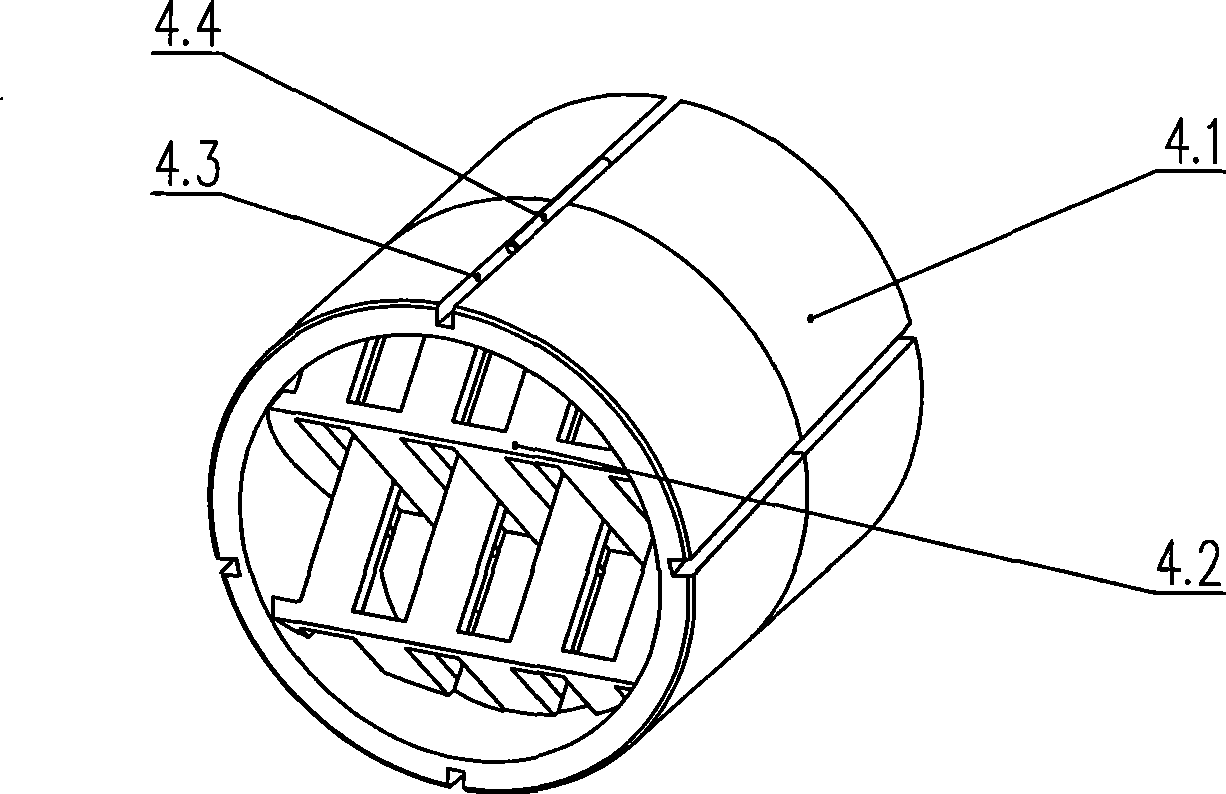

[0017] Such as figure 1 , figure 2 , image 3 As shown, the plastic melt color mixing device of the plastic pipe extruder of the present invention is characterized in that it includes a transition coupling body 3, a front transition sleeve 6, a rear transition sleeve 2, a heating ring 5 and at least two color mixing components 4. The number of color mixing components in this embodiment is eight. The heating ring 5 is arranged on the outer circumferential surface of the transition coupling body 3 to heat the plastic melt flowing through the color mixing assembly 4, and the color mixing assembly 4 is sequentially arranged in the inner cavity of the transition coupling body 3, and the two ends are respectively connected to the front The transition sleeve 6 and the rear transition sleeve 2 are opposed to each other, and the following connection is specifically ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com