Fabricated toilet convenient to mount and mounting method thereof

A prefabricated and bathroom technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of complex installation and decoration process, long installation period, low installation efficiency, etc., to reduce material costs and reduce interference between upstairs and downstairs Less, the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

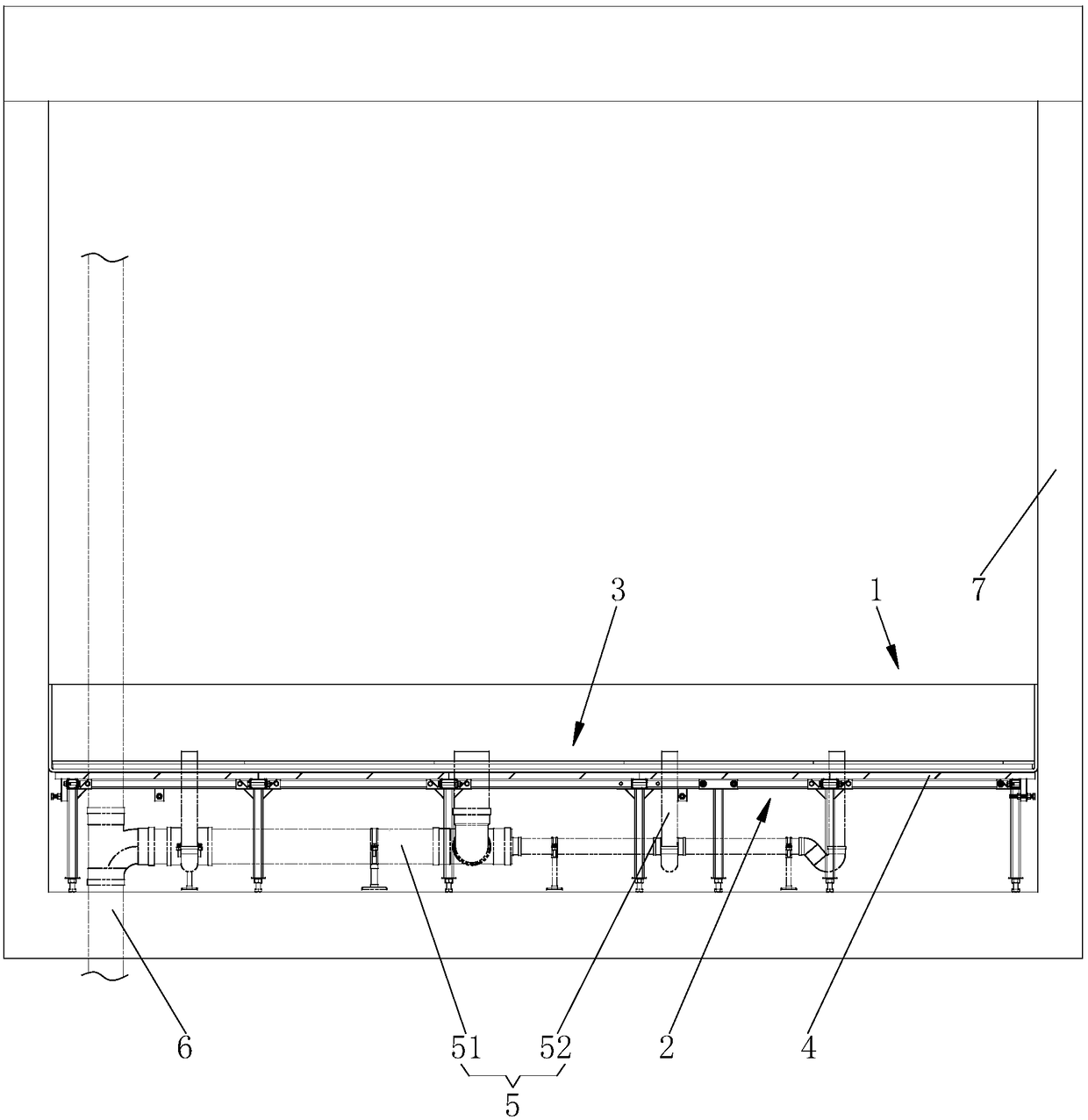

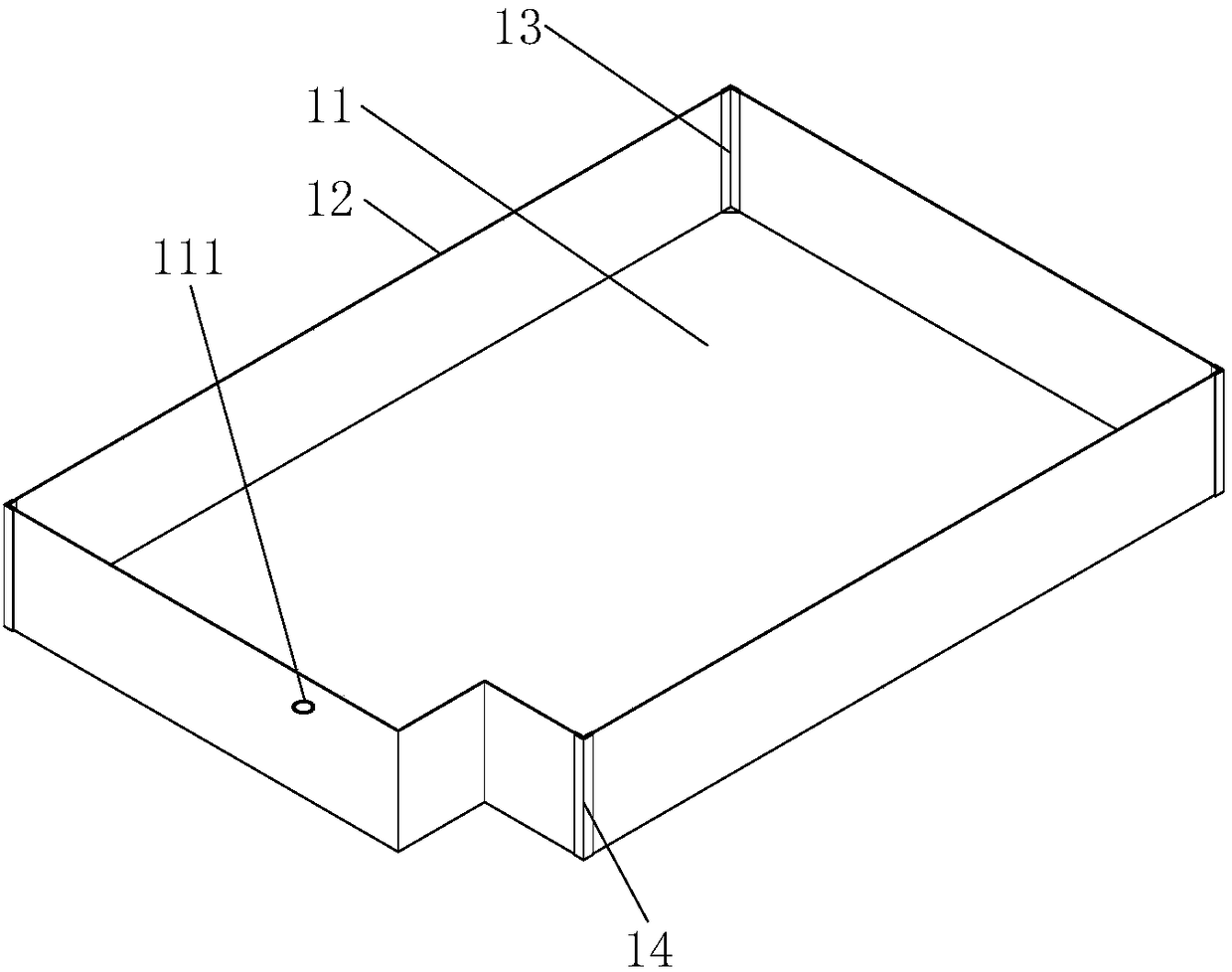

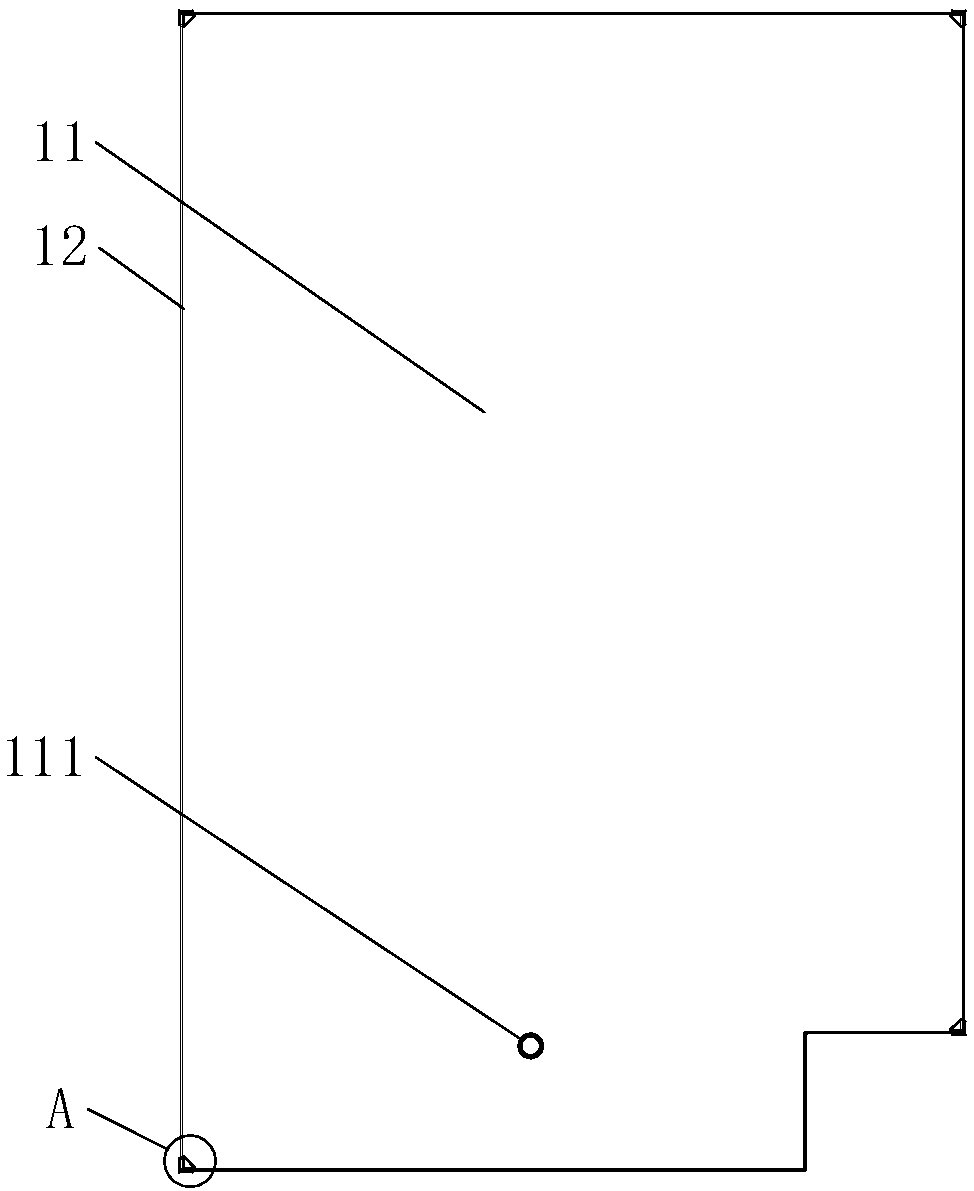

[0053] Such as figure 1 As shown, a prefabricated toilet in this embodiment has a steel frame 2, a flexible waterproof pan 1, a prefabricated floor and drainage pipes 5 on the same floor, the above-mentioned steel frame 2, flexible waterproof pan 1, prefabricated floor and drainage pipes on the same floor Pipe 5 is all arranged in toilet 7.

[0054] Such as figure 1 with Figure 13 As shown, in this embodiment, the steel frame 2 is arranged on the upper side of the toilet 7, and the steel frame 2 has a keel 21, a vertical support frame 22 and a horizontal support frame 23, wherein the keel 21 constitutes a rectangular platform with a gap at one corner and the rectangular platform The inner keel 21 is a grid; vertical support 22 is used to support the keel 21 and adjust the height of the keel 21, and the horizontal support frame 23 is fixed on the keel 21 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com