Experiment method for observing three-dimensional square crack damage and strain field as well as experiment apparatus thereof

An experimental method and strain field technology, applied in the fields of surveying and geotechnical engineering, can solve the problems that the strain field cannot be tested, the problem of three-dimensional crack expansion has not been well solved, and the development cannot accurately observe the three-dimensional crack failure mode, etc., to achieve The effect of the production process is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

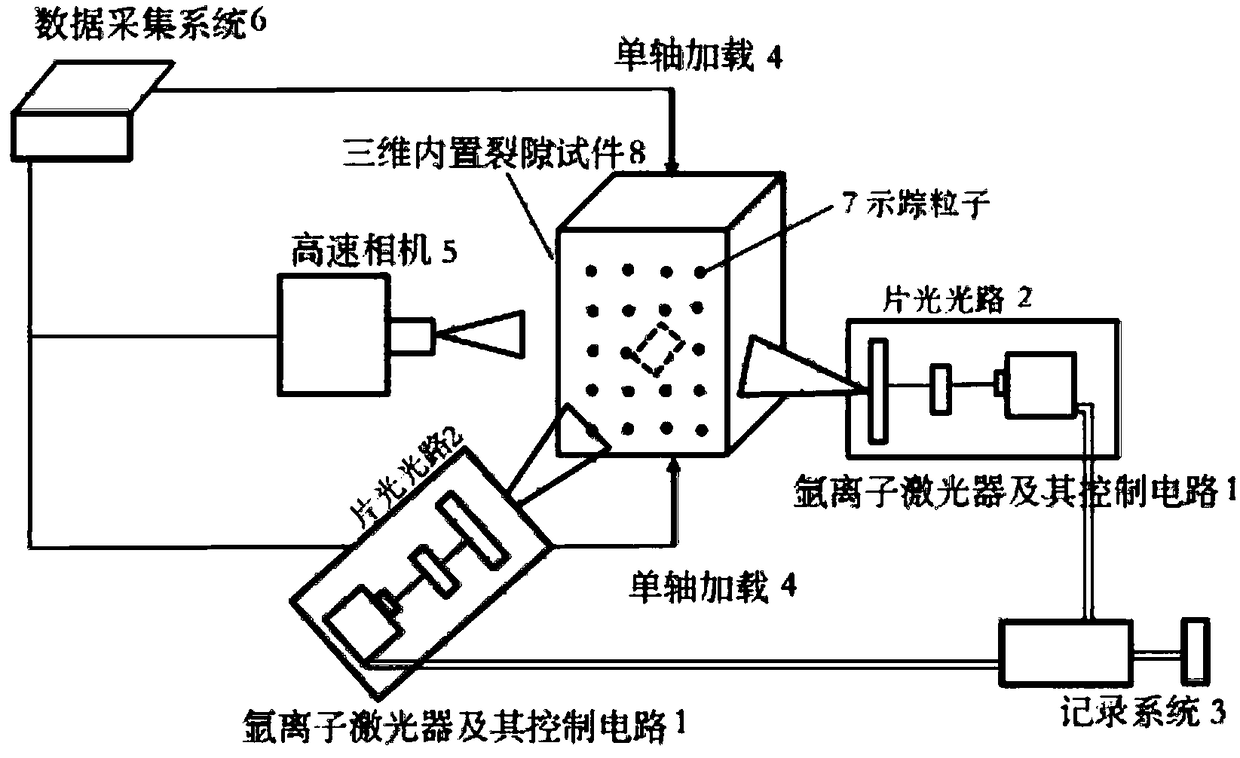

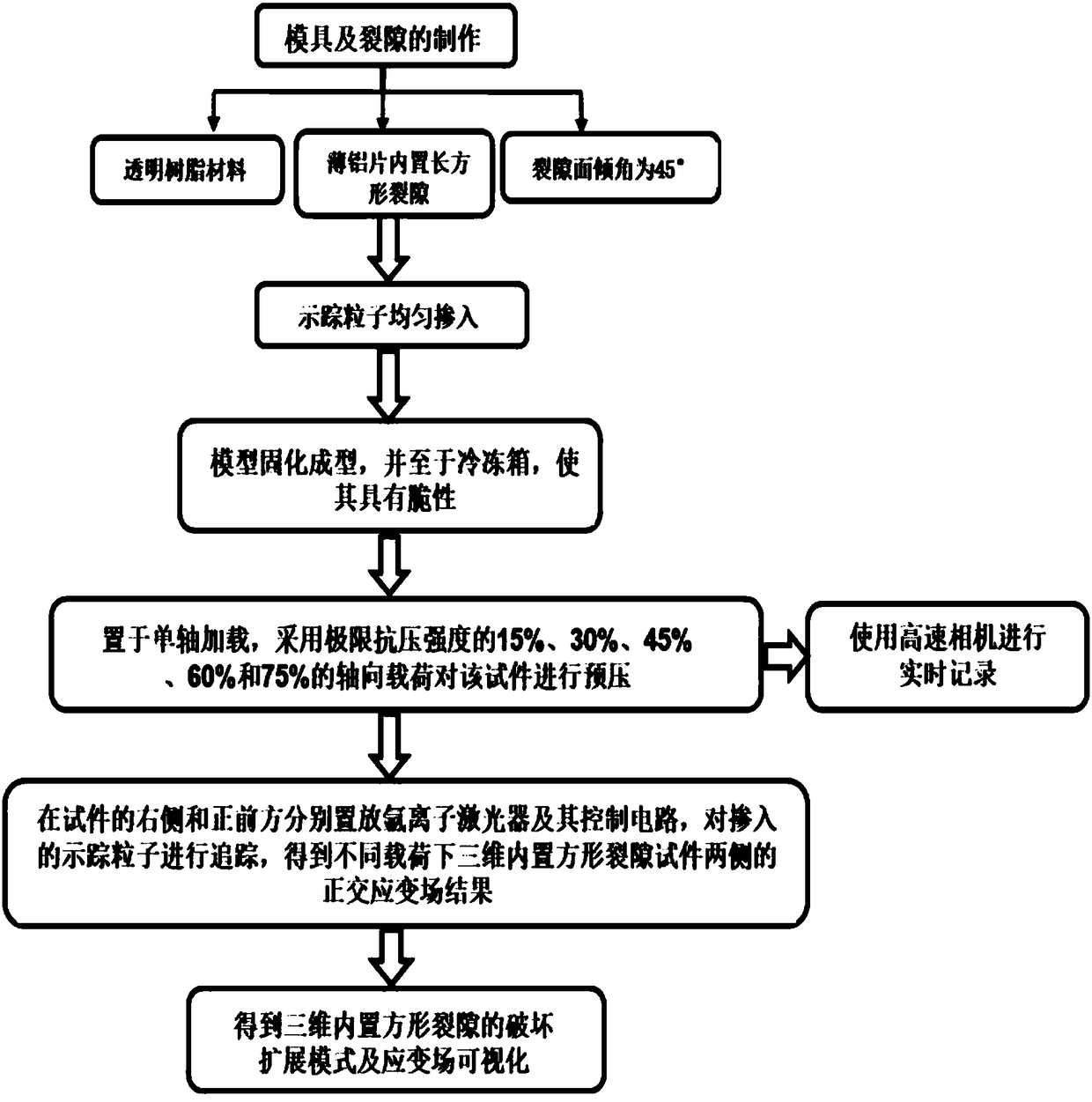

[0033] In this embodiment, the experimental method for observing three-dimensional crack damage and strain field, the specific steps are as follows:

[0034] 1. The production of the mold and the crack: the mold is made of unsaturated resin, and the length, width and thickness of the mold are 100, 100 and 50mm respectively. The upper mouth of the mold is open and the lower end is closed, and small holes are drilled on both sides of the mold. Using a thin aluminum sheet to simulate primary cracks, the propagation and penetration process of parallel three-dimensional crack groups under uniaxial compression was studied. According to the needs of the experiment, the length, width and thickness of the thin aluminum sheet are cut to 30, 25 and 8mm respectively. The inclination angle of the fracture surface (the angle with the loading direction) is 45°. Fix the prefabricated rectangular slit inside the mold by passing a thin cotton thread through the small hole, and seal the small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com