Power battery tab die-cutting and winding integrated machine

A technology of power battery and all-in-one machine, which is applied in the field of winding of power battery cells, can solve the problems of waste of pole piece coils, long time consumption, affecting the winding efficiency and yield of cells, etc., so as to improve efficiency and yield , Improve production efficiency and product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

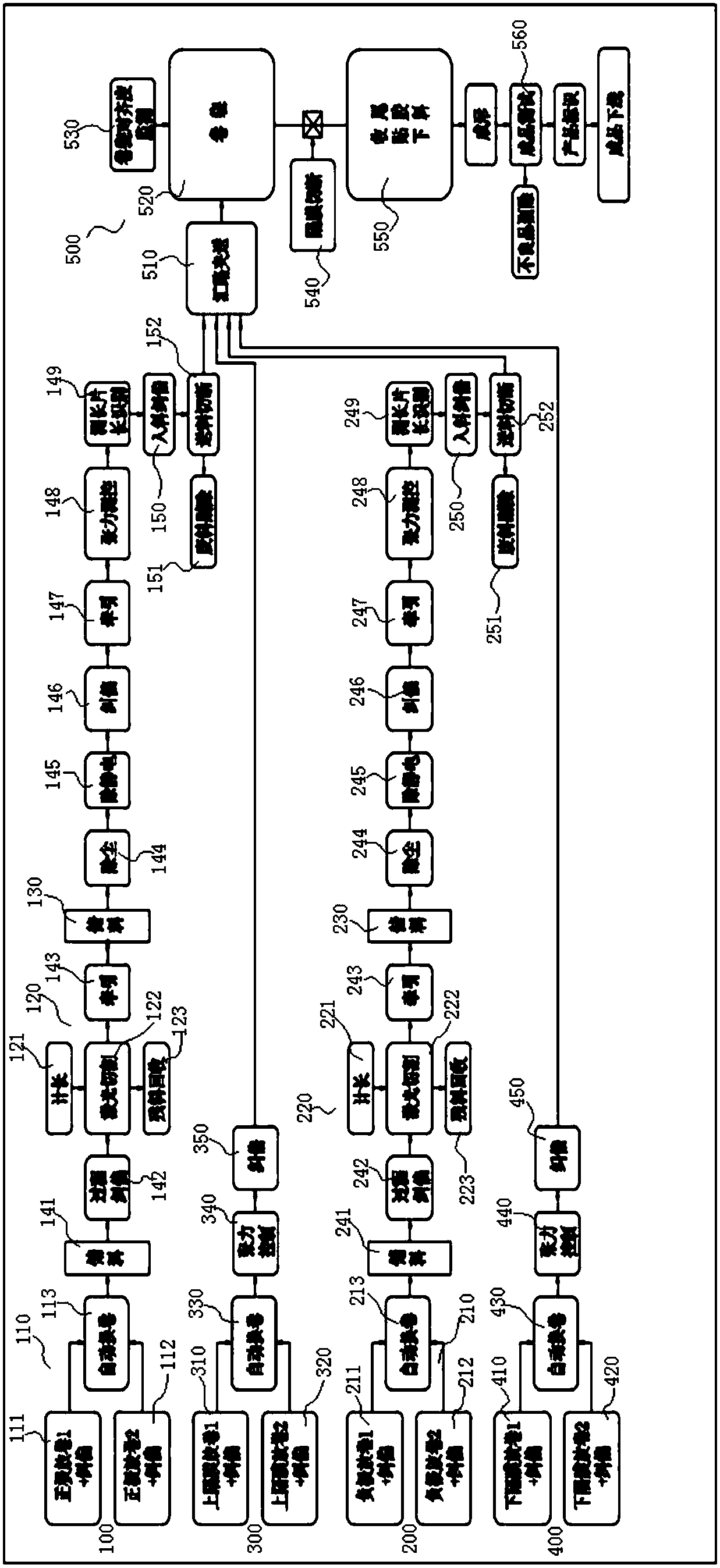

[0036] In this example, the power battery tab die-cutting and winding integrated machine organically integrates the tab die-cutting process and the cell winding forming process in the cell forming process, and realizes the combination of tab die-cutting and cell winding forming. Simultaneously, so that the die-cut tab material enters the cell winding and forming process in real time for direct cell winding and forming, which can greatly improve the production efficiency of the product, and at the same time make the tabs on the wound and formed cells neat Uniform, greatly improving the performance of the product.

[0037] see figure 1 , which shows an example diagram of the functional principle of the power battery tab die-cutting and winding ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com