Vehicle-mounted camera

A camera and lens technology, applied in the camera field, can solve problems such as severe image noise, easy deformation of gaskets, and waterproof failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

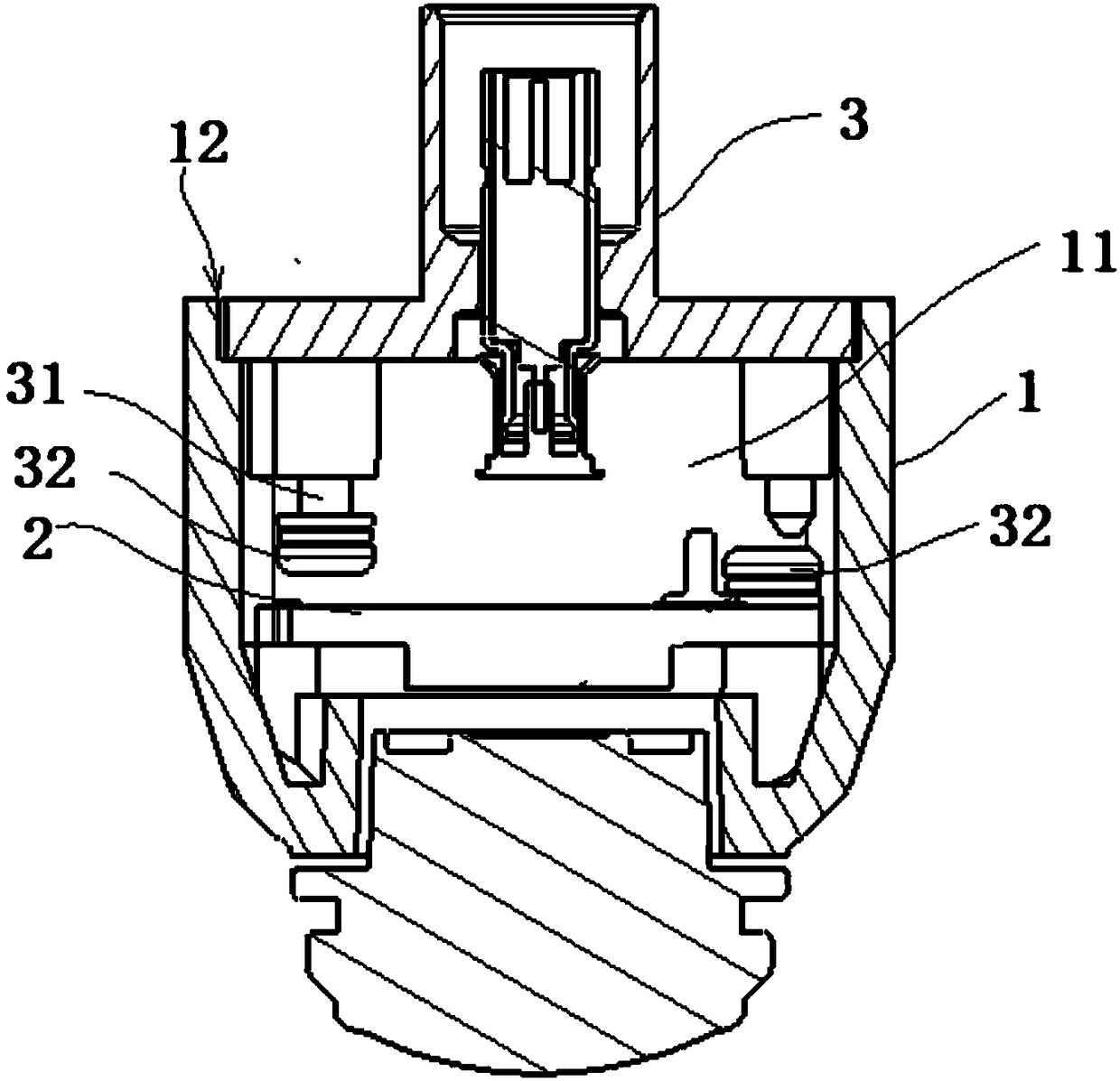

[0019] Example: such as figure 1 As shown, a vehicle-mounted camera includes a lens housing 1 , a circuit board 2 , and a rear housing 3 .

[0020] Wherein, a mounting slot 11 is provided at the rear end of the lens housing 1 , and a groove 12 is provided inside the notch of the mounting slot 11 . The rear casing 3 is sealed and welded in the groove 12 by laser.

[0021] The circuit board 2 is fixed in the installation groove 11 by screws, and faces the lens in the lens housing 1; the rear housing 3 and the lens housing 1 are metal housings, which are beneficial to heat dissipation.

[0022] A guard is provided between the circuit board 2 and the rear case 3 . The guard includes a column 31 and an elastic ring 32, which is arranged on the side of the rear housing 3 facing the circuit board 2, the elastic ring 32 is sleeved on the front end of the column 31, and is pressed between the column 31 and the Between the above-mentioned circuit substrates 2.

[0023] The rear hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com