Vegetable greenhouse capable of automatically removing snow and controlling temperature

An automatic technology for vegetable greenhouses, applied in snow traps, greenhouse cultivation, roofing, etc., can solve the problems of collapsed greenhouses, losses, high maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The invention utilizes the heat exchange tube to access heat, and exchanges energy with the greenhouse through the cooling fins, thereby changing the temperature of the insulation layer of the greenhouse, and in winter, the heat exchange tube can be connected to an independent heating boiler or an urban heating system; , as required, the heat exchange tubes can pass cold water to cool down the temperature, so as to realize the warm winter and cool summer of the greenhouse. The structure of the present invention will be described below using specific embodiments.

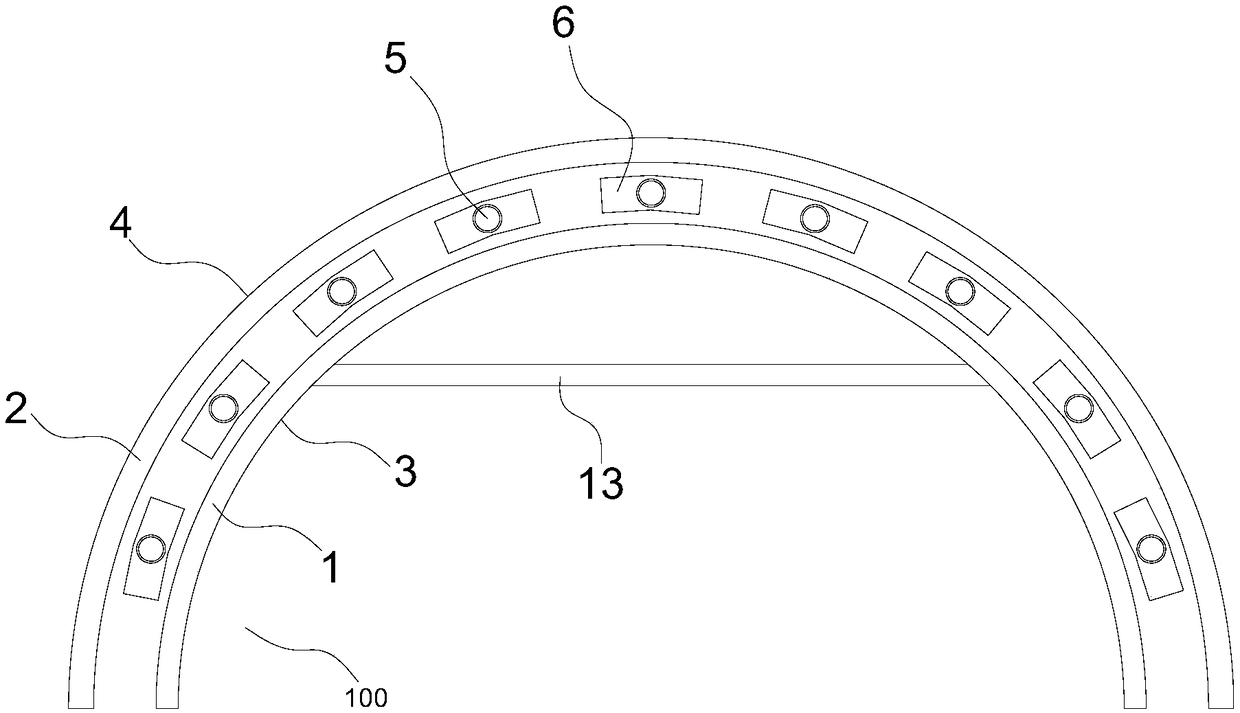

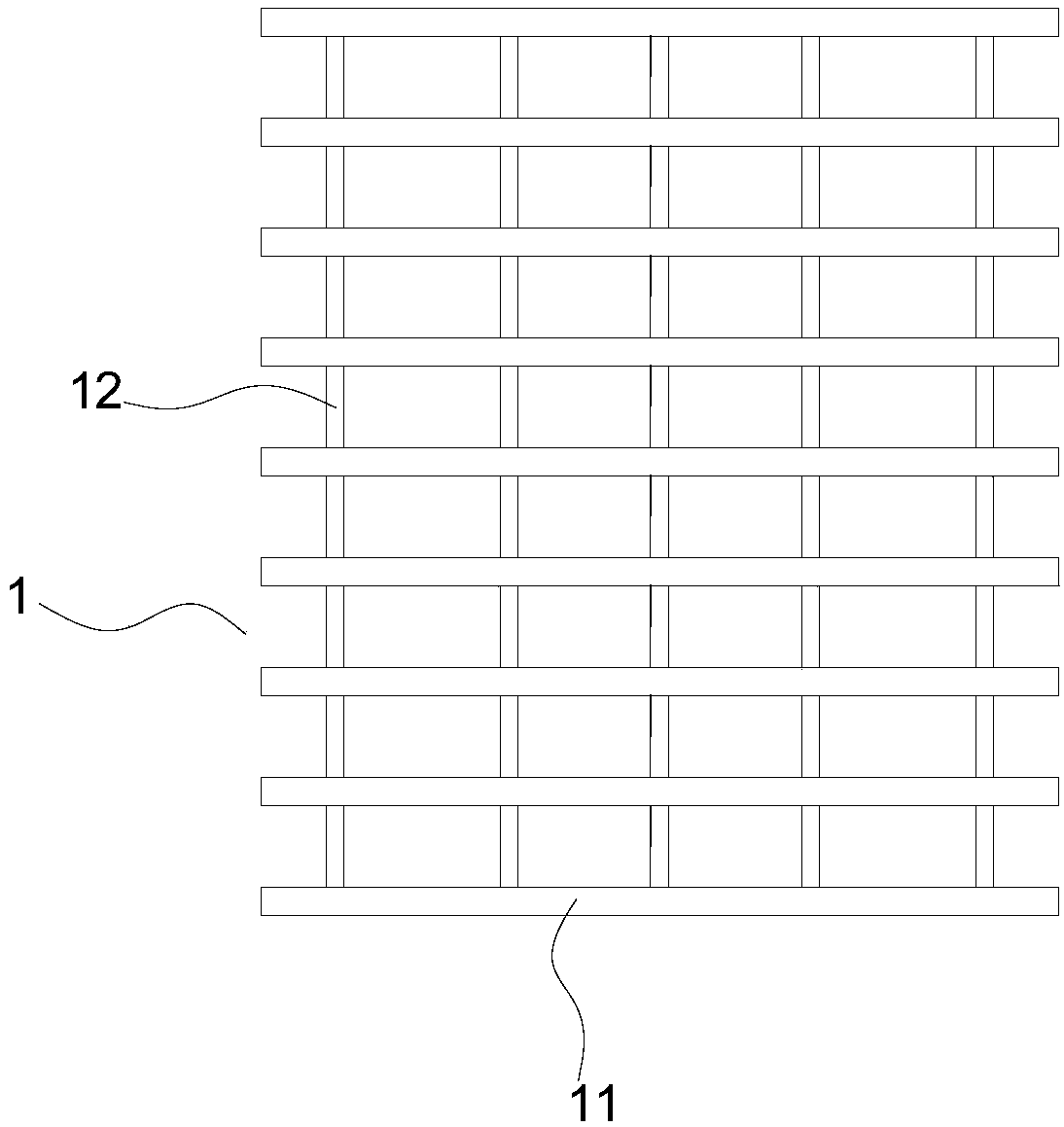

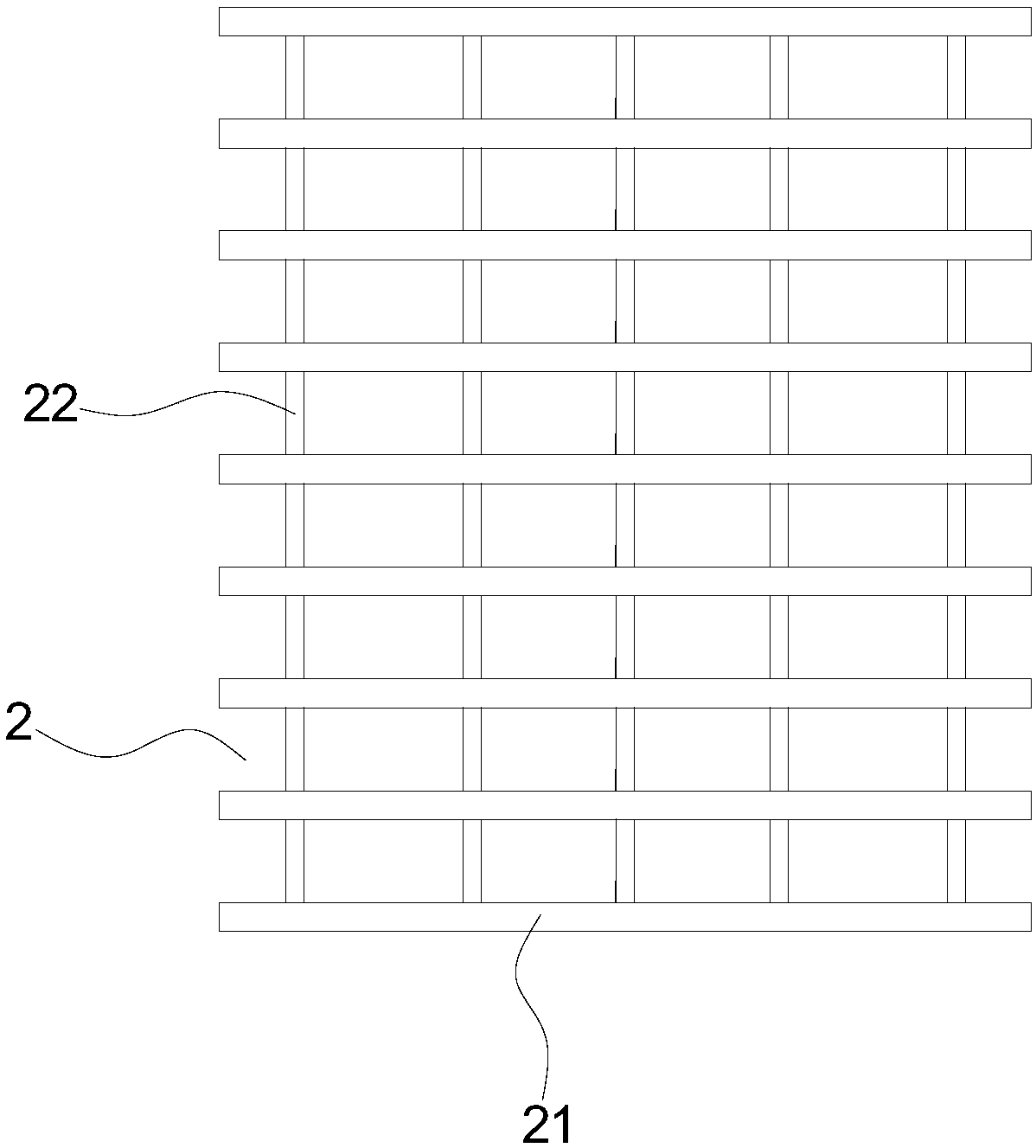

[0024] Please refer to Figure 1 to Figure 4 , a vegetable greenhouse capable of automatic snow removal and temperature control, including a greenhouse main body 100, the greenhouse main body 100 includes an inner shed skeleton 1 and an outer shed skeleton 2, and the inner shed skeleton 1 and the outer shed skeleton 2 are arc-shaped steel frame structures The inner side of the inner shed skeleton 1 is laid wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com